Framo Cargo Pump SD125-5/ SD150-5

INSTRUCTION FOR MAINTENANCE AND REPAIR

No.

Date/sign.:

Page:

Rev. B:

1000-0131-4

Jan99/AGAa

5 of 21

22Feb06/JEB

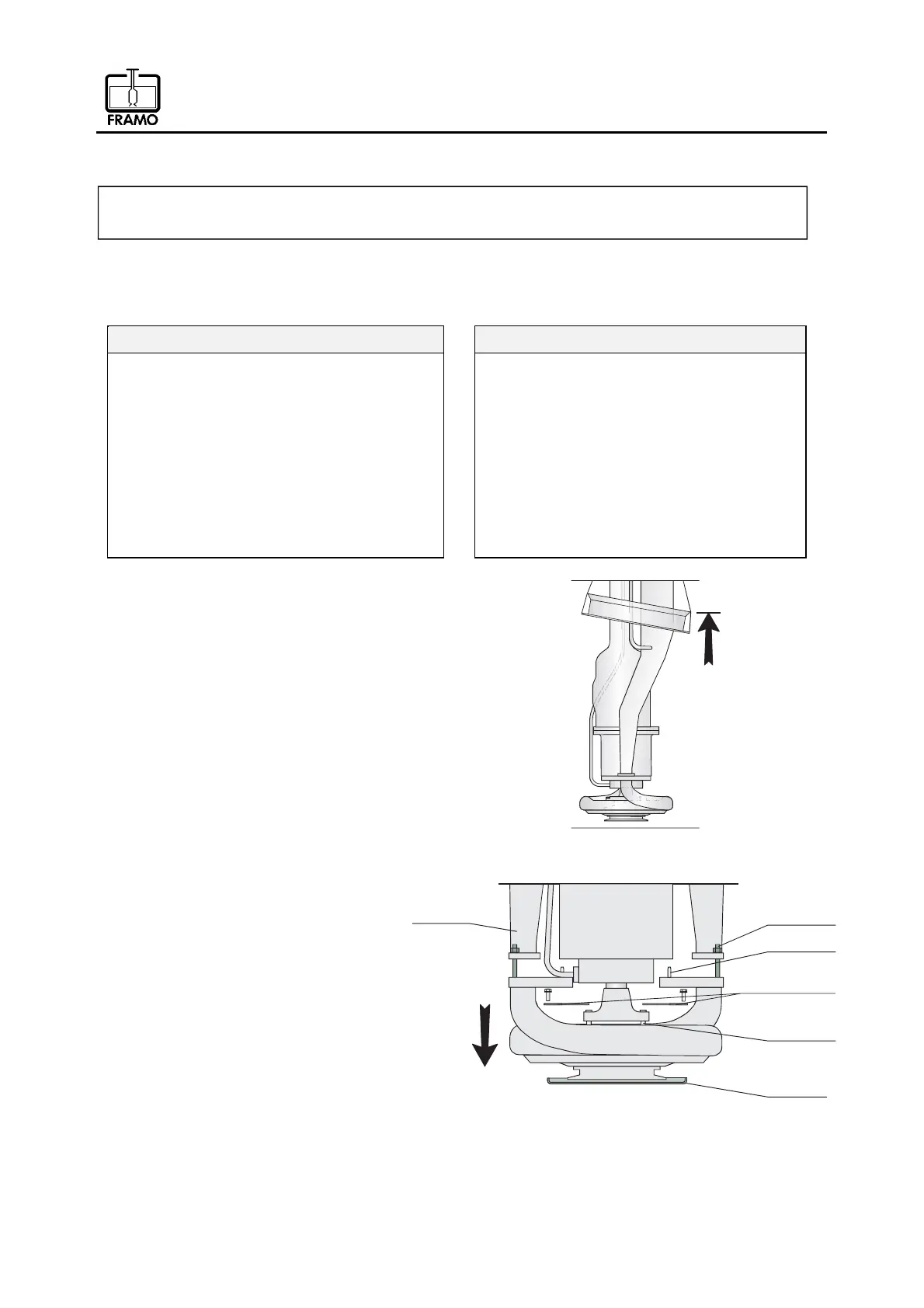

Ô·º¬·²¹¾±´¬-

Ù«·¼·²¹°·²

λ¼«½·²¹°´¿¬»-

Þ±´¬º±®

·³°»´´»®¸«¾

ʱ´«¬»½¿-·²¹

Ы³°«²·¬

É»·¹¸¬½¿ò

ìëµ¹

Ý¿®¹±´»¹

Í´·¼»¬±±´

Fig. 3

2 MAINTENANCE INSTRUCTION

2.1 Dismantling of impeller / wear rings

Standard tools Special tool

Name Name

Allen key 10 mm Threaded bolt M12 x 250

Spanner 13 mm Hexagon nut M12, 2 pcs

Spanner 16 mm Washer 12, 2 pcs.

Spanner 18 mm

Spanner 24 mm

Plastic hammer

Slide tool

Anti rotating tool for impeller hub (for assembling)

Torque wrench

Loosen the bottom support.

Lift and secure the support to pipe stack.

Remove reducing plates.

Loosen bolts for impeller hub two

turns. Knock carefully on (or press

down) all bolts. When impeller is

loose remove all bolts. Remove bolts

between volute casing and cargo leg.

Replace one bolt between volute

casing and pump unit diagonal on

each side of the pump with lifting

bolts(M12x250). Remove remaining

bolts between volute casing and

pump unit.

Lower volute casing, suction cover,

impeller and wear ring in one piece.

Before doing service on pump read the Operation Manual for Cargo Pumps, Chapter 3,

Maintenance information.

Fig. 2

Loading...

Loading...