QUICKSTART GUIDE

Electrical Installation

3

Electrical Installation

Wiring Guidelines

1. Mount the drive as close as possible to the service entrance panel. Wire directly to the service entrance.

Do not connect to a sub-panel.

2. Use a dedicated branch circuit for the drive.

3. Route motor wiring out of the building as soon as possible. Separate input power and motor wiring by

at least 8 in. (20.3 cm).

4. Cross over other branch circuits and facility wiring at a 90 angle. If it is necessary to run wiring in par-

allel, separate by at least 8 in. (20.3 cm).

5. All control wiring—sensors, switches, transducers, etc.—should be in a separate conduit routed individ-

ually, not parallel, from high voltage wiring. In addition, any shielded cables should be properly

grounded.

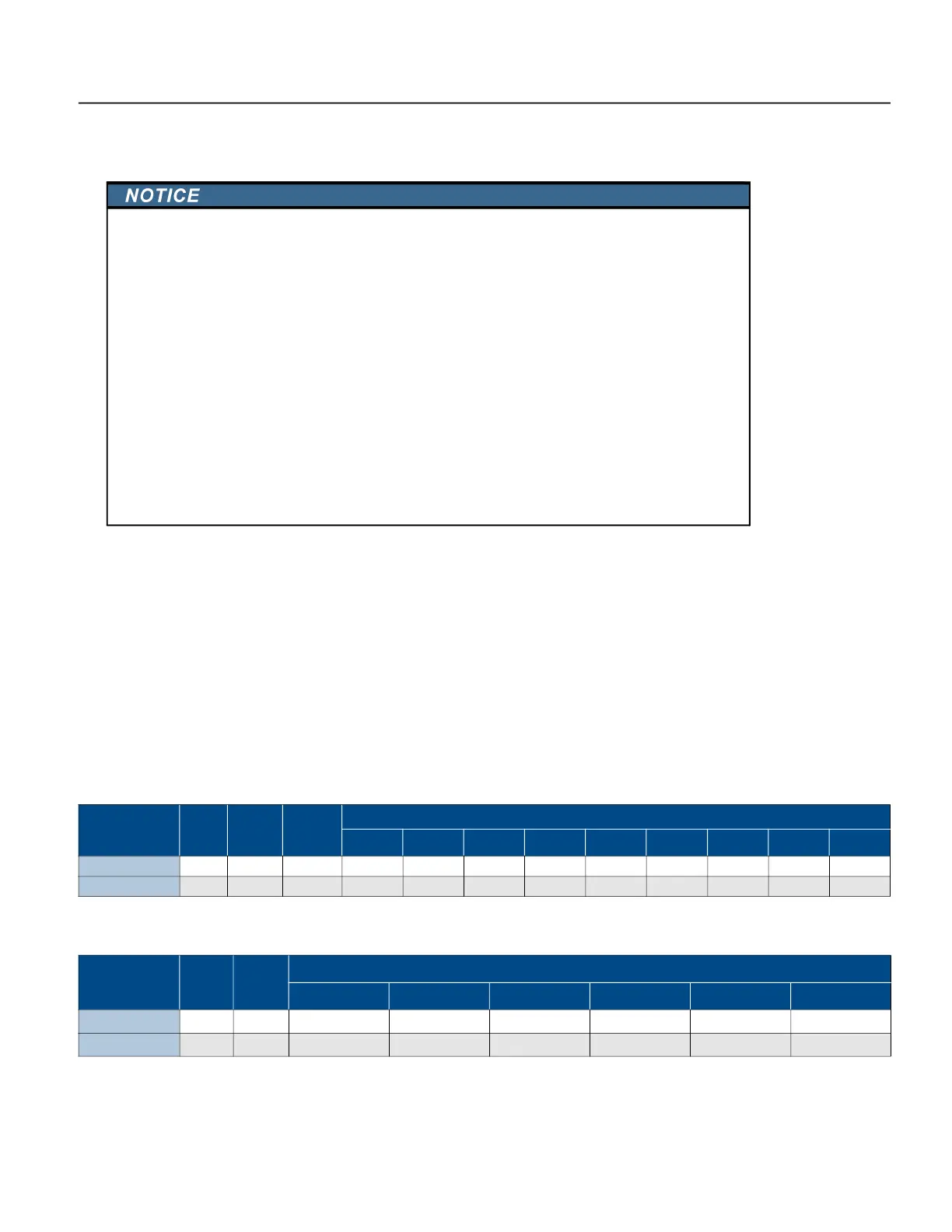

Fuse/Circuit Breaker and Wire Sizing

Verify that the dedicated branch circuit for the drive is equipped with a properly-sized circuit breaker.

1

Based on a 3% voltage drop.

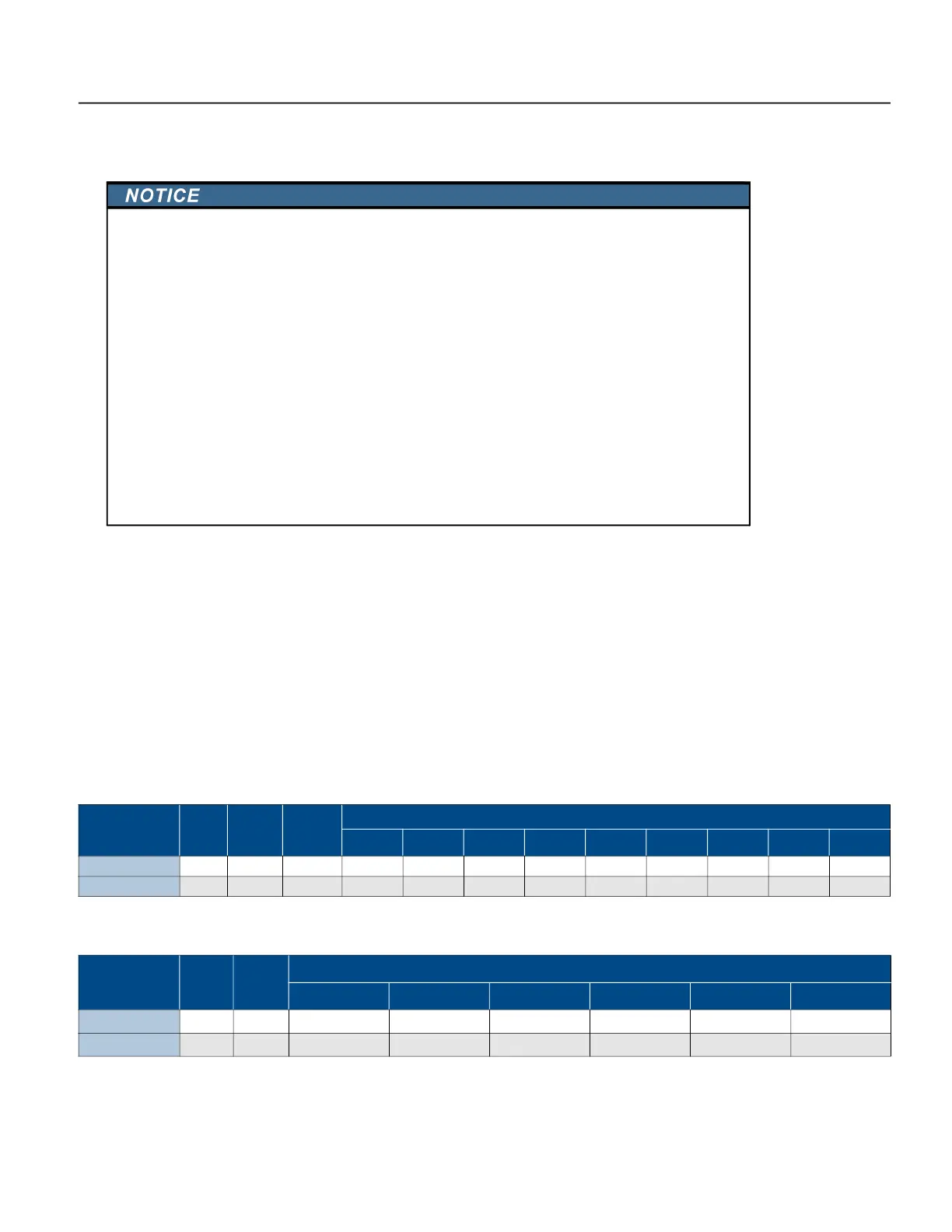

Maximum Motor Cable Length

1

Based on a 5% voltage drop.

NOTE: Flat-jacketed submersible motor cable is recommended. Cable lengths shown are for the highest

power motor supported.

Risk of damage to VFD

, or malfunction can occur.

Follow all wire routing and grounding instructions carefully. Inductive currents caused by parallel wiring,

or close proximity between high voltage and control wiring can cause unexpected behaviors.

• Do not run input power and motor wires in the same conduit.

• Do not run motor wires from multiple VFDs in common conduit.

• Do not run control wiring parallel with high voltage wiring.

• Do not install a magnetic contactor or disconnect in the motor circuit.

• Do not run VFD wiring parallel with house or out-building wiring.

• Do not use aluminum wires for VFD connections.

• Do not use with a Ground Fault Circuit Interrupter (GFCI).

• All wiring must comply with the National Electrical Code and local codes.

• Improper splicing or damage to motor cable insulation may expose the conductor(s) to moisture and

can produce motor cable failure.

• For retrofit application, make sure to check the integrity of power and motor leads. This requires

measuring the insulation resistance with a suitable megohm-meter.

Model

Input

Volts

Rated

Input

Amps

Fuse or

Breaker

Amps

AWG Copper Wire Sizes, 90° C Insulation, and Panel to Drive Cable Lengths (in feet)

1

10 8 6 4 3 2 1 1/0 2/0

SDCP-SUB2043

460 V 42 A 50 A 281 417 639 969 1172 1433 1711 2041 2443

SDCP-SUB1023

230 V 46 A 50 A 124 185 284 432 523 640 766 916 1098

Model

Output

Volts

Rated

Output

Amps

AWG 600V Copper Wire Sizes, 90° C Insulation, and Motor Cable Lengths (in feet)

1

10 8 6 4 3 2

SDCP-SUB2043

460 V 30 A 410 650 1030 – – –

SDCP-SUB1023

230 V 32.5 A 190 310 490 760 950 1000

Loading...

Loading...