rod ends are threaded in the cross tube past the

clamps and the slots at the cross tube ends.

9. Check the zerk fittings for damage. If a zerk

fitting is damaged, replace it.

Some tie rod ends have no zerk fittings because

they are not greaseable. Do not install a zerk

fitting on a nongreaseable tie rod end.

10. Check that the cotter pin is in place. If it is not,

tighten the tie rod end nut to one of the following

specs depending on the size of the stud.

• 7/8–14, 160 to 300 lbf·ft (217 to 406 N·m)

• 1–14, 250 to 450 lbf·ft (339 to 610 N·m)

• 1-1/8–12, 350 to 650 lbf·ft (475 to 881

N·m)

• 1-1/4–12, 500 to 675 lbf·ft (678 to 915

N·m)

11. Check the steering arm bolts for a minimum

torque of 300 lbf·ft (406 N·m). If the steering arm

bolt torque has fallen below this specification,

remove the bolt, clean all the threads, and apply

new Loctite® 680. Tighten the bolt 300 to 450

lbf·ft (406 to 610 N·m).

12. Remove the chocks from the tires.

33–05 Wheel End Inspection

and Maintenance, 6,000-

Pound and 8,000-Pound

Steer Axles with Oil-

Lubricated Hubs

Periodic inspection and maintenance of wheel ends

on 6,000-pound and 8,000-pound steer axles is

essential to sound wheel bearing performance.

Check for leaks at the oil seal and hub, and inspect

the lubricant per the maintenance intervals provided

in

Group 00 of this manual.

Oil Seal Leak Check

Check for evidence of oil leakage at the oil seal. If a

leak is found, replace the seal. See Group 33 of the

Business Class M2 Plus Workshop Manual for

instructions.

Hub Cap Leak Inspection

Check for evidence of oil leakage between the hub

cap, gasket and hub surface. If leakage is evident,

replace the gasket with a new one. See Section

33.01, Subject 100 of the Business Class M2 Plus

Workshop Manual for instructions.

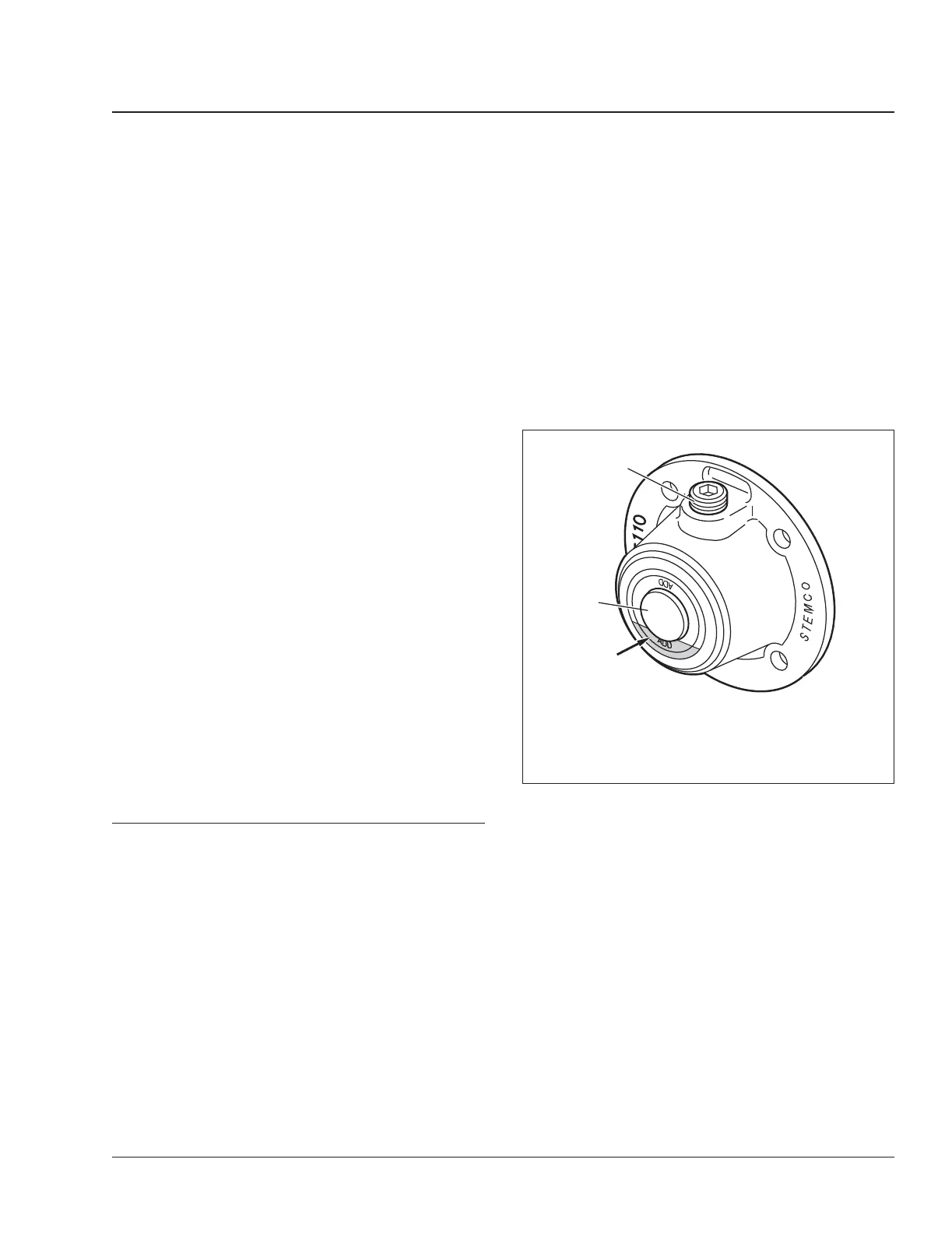

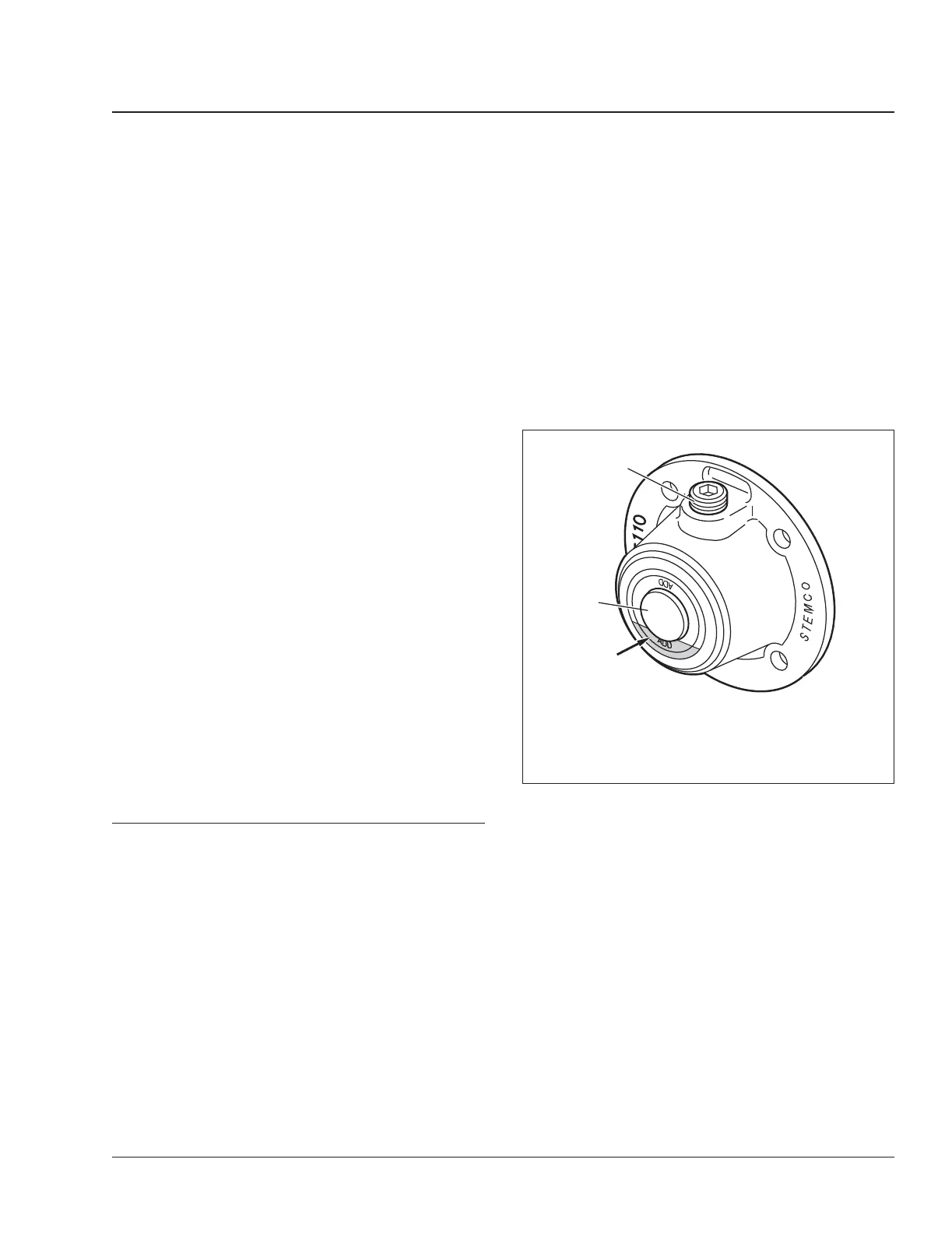

Check for a missing hub cap fill plug or vent plug.

See

Fig. 9. Replace any missing parts. If a vent plug

is missing, the oil quality is compromised and must

be replaced. See Group 33 of the Business Class

M2 Plus Workshop Manual for instructions.

Lubricant Inspection

Rotate the hub so that the fill plug is down, and drain

a small sample of hub oil into a plastic container that

is free of debris, especially any metallic particles.

Then use a magnet to probe the sample. Note

whether there is substantial metallic debris present,

and compare the oil color to new approved oil.

Acceptable oil will have a color similar to new oil and

have no water or metal contaminants.

If the oil is not acceptable, inspect the bearings for

damage. Replace the bearings as needed, and install

the hub per Group 33 of the Business Class M2

Plus Workshop Manual.

f330247a

A

1

2

01/05/2009

A. Hub Cavity Full

1. Vent Plug

2. Magnetic Drain/Fill Plug

Fig. 9, Stemco Hub Cap

Front Axle 33

Business Class M2 Plus Maintenance Manual, 02/10/2023 33/5

Loading...

Loading...