Maintenance at

every start-up

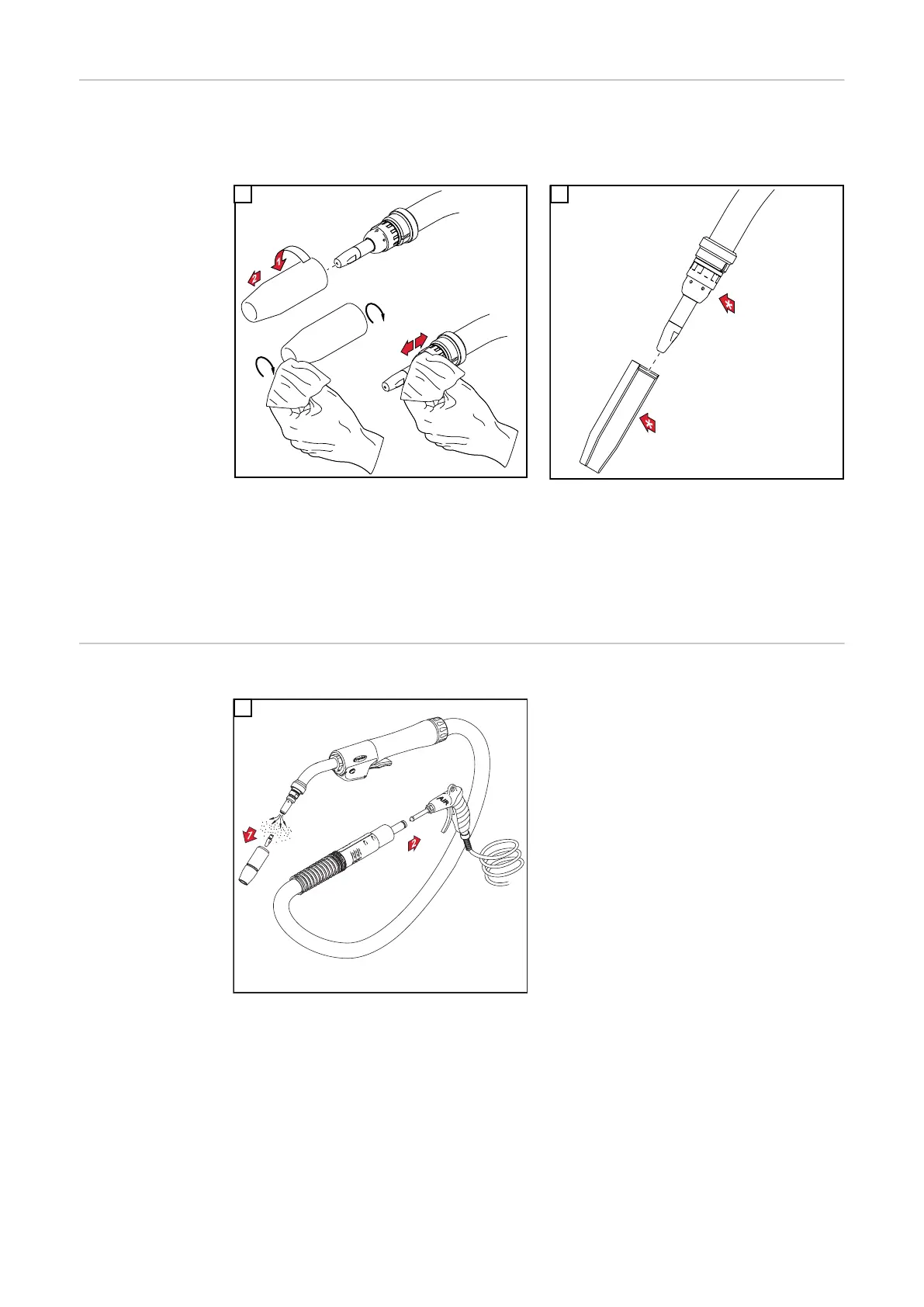

- Check wearing parts

• Replace defective wearing parts

- Purge the gas nozzle of welding spatter

1 2

* Check gas nozzle, spatter guard, and insulations for damage and replace dama-

ged components.

- In addition to the steps listed above, prior to starting up water-cooled welding tor-

ches always:

• Ensure that all coolant connections are leak-tight

• Ensure that there is a proper coolant return flow

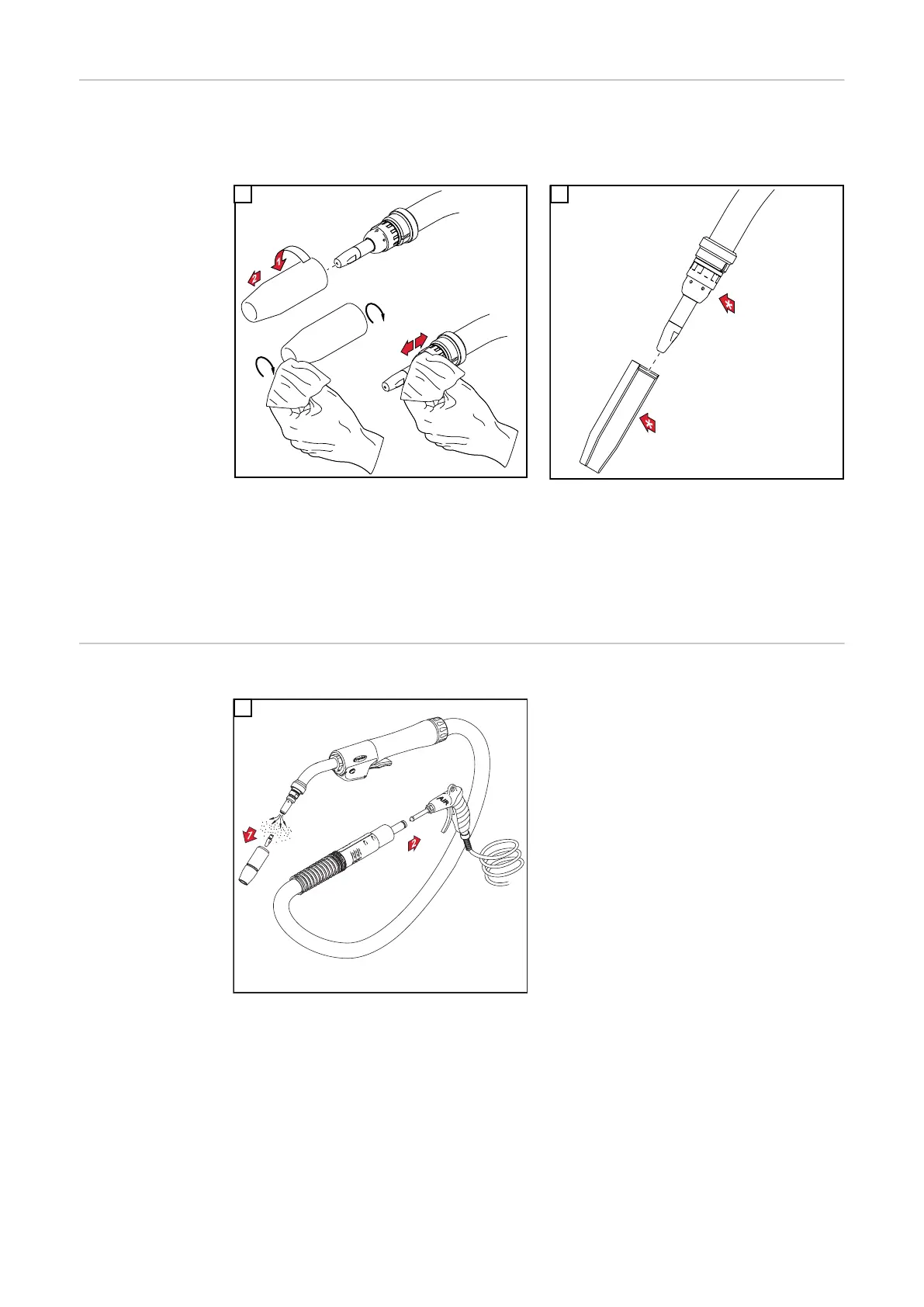

Maintenance at

every wire spool/

basket-type spool

replacement

Clean the wirefeeding hose with reduced compressed air:

1

44

Loading...

Loading...