2-4

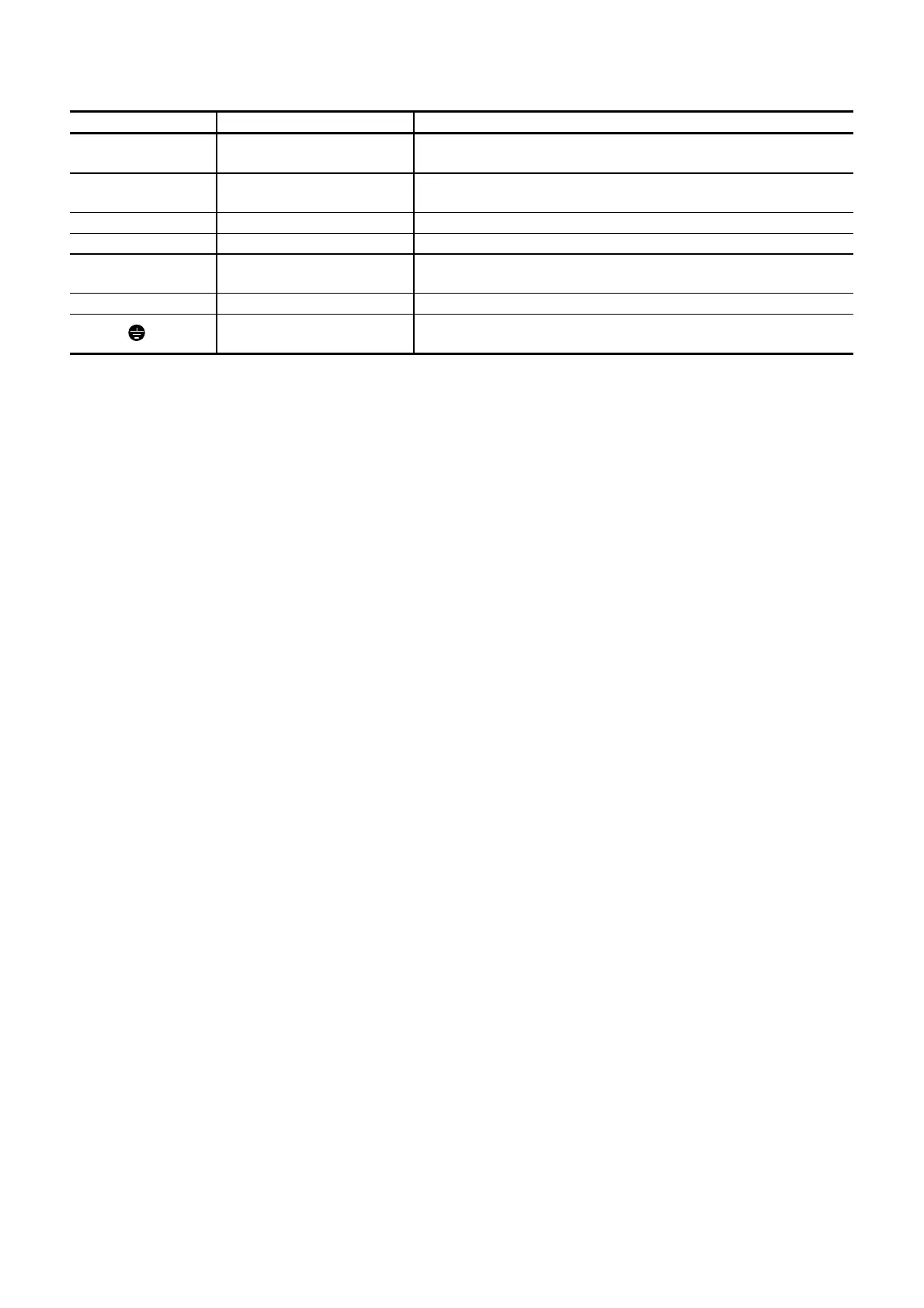

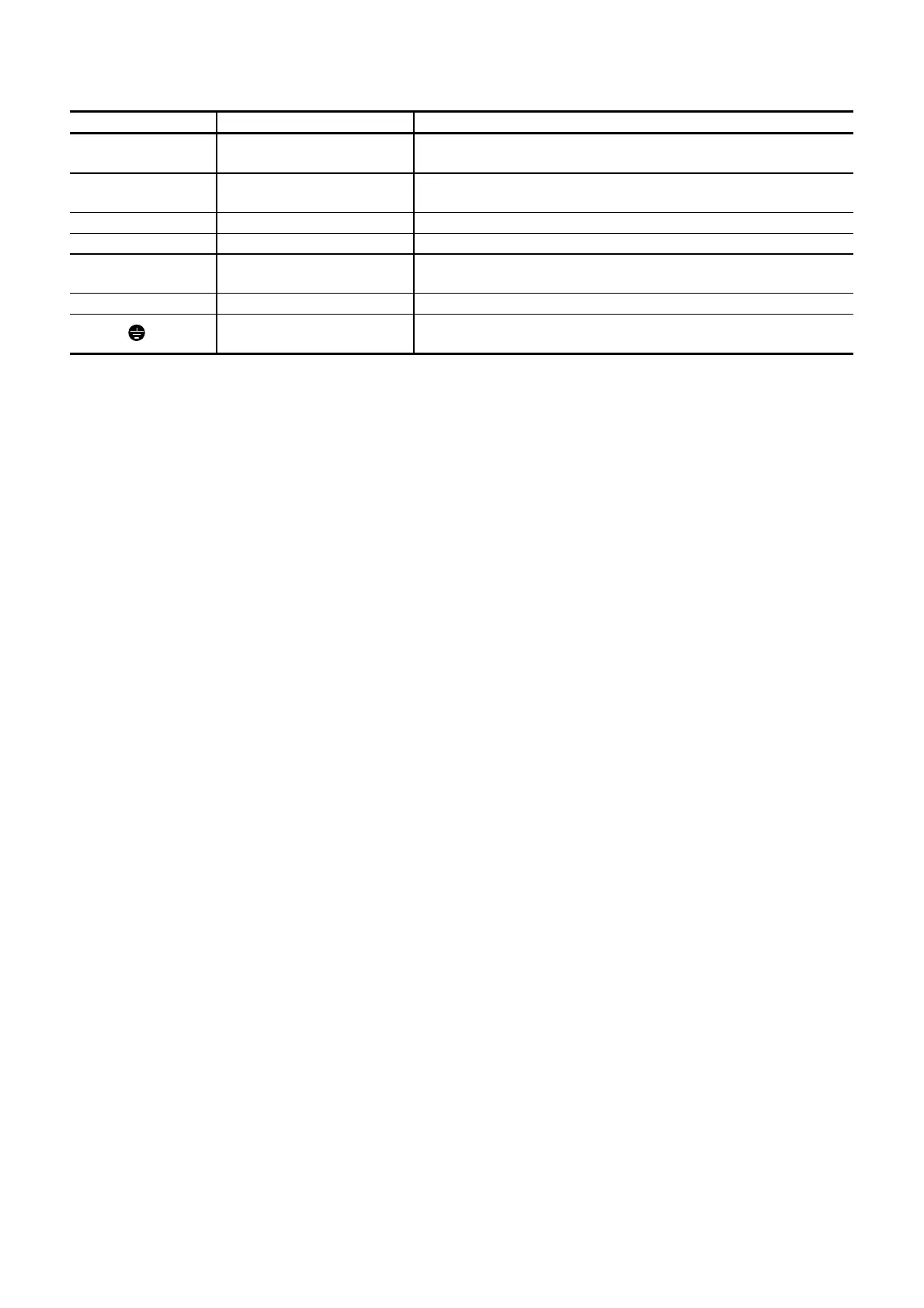

2-3-2 Connection of Main Circuit and Grounding Terminal

Table2-3-1 Connection of Main Circuit and Grounding Terminal

Symbol Name of terminal Description

L1/R,L2/S,L3/T

Main circuit power

input

Connects a 3-phase power supply.

L1/L,L2/N

Main circuit power

input

Connects a 1-phase power supply.

U,V,W

Inverter output Connects a 3-phase induction motor.

P1,P(+)

For DC reactor Connects an optional DC reactor.

P(+),DB

For external braking

resistor

Connects an optional external braking resistor.

P(+),N(-)

DC link circuit terminal Connected to DC link circuit.

G

grounding Grounding terminal of the inverter chassis (housing).

Connect to the protective ground.

(1) Main circuit power input terminal (L1/R, L2/S, L3/T,L1/L,L2/N)

a. Connect the main circuit power input terminals to the power supply through a circuit breaker

for circuit (wiring) protection or an earth leakage breaker. There is not need to match the

phase sequence.

b. It is recommended to connect a magnetic contactor to disconnect the inverter from the power

supply to prevent a failure or accident from becoming serious upon activation of the

protective function of the inverter.

c. Do not turn the main circuit power supply on or off to start or stop the inverter. Instead, use

control circuit terminals FWD and REV or the RUN and STOP keys on the keypad panel. If it

is unavoidable to turn the main circuit power supply on or off to start or stop the inverter, limit

the frequency to once an hour or fewer.

d. Do not connect to a single-phase power supply for 3-phase input inverter.

(2) Inverter output terminals (U, V, W)

a. Connect these terminals to a 3-phase motor with the correct phase sequence. If the direction

of rotation does not match the operation direction, change arbitrary two cables among the U,

V and W phases.

b. Do not connect a phase advance capacitor or surge absorber to the inverter output.

c. If the wiring length between the inverter and the motor is extremely long, the stray capacity

between cables causes a high frequency current, possibly tripping the inverter due to an

overcurrent, increasing the leakage current, or deteriorating the current detection accuracy to

cause deterioration of the performance or other phenomena. To prevent such trouble, limit

the wiring length of the motor to 50 m for 4.0 kW or a smaller output or to 100 m for a larger

output.

Note: When a thermal relay is installed in the path between the inverter and the motor, or especially

in the case of a 400V system, the thermal relay may malfunction even with a wiring length

shorter than 50 m. In such a case, add an OFL filter or lower the Motor sound adjustment

(carrier frequency) of the inverter. ... Function code F26 Motor sound adjustment.

Loading...

Loading...