Note 1: To return to a previous menu level, keep the / pressed.

Note 2: The alarm duration time and the maximum measured temperature can be updated while the

alarm is ocurring.

To delete all HACCP alarm records follow the steps below:

a) Enter the main function menu by simultaneously pressing < and> (short press) during temperature

display;

b) Select [Code] option in the menu and press/:

c) Using the< or> keys enter the access code 123 (one hundred and twenty three) and confirm

with/;

d) Using the <or>keys again, enter the [HACC] menu and select the [Hrst] option and press /;

e) If you are sure you want to permanently delete the HACCP alarm logs and if the access code has

been entered correctly, use the <or> keys select the [,yes]option and press/;

f) The message [rset] will be displayed and all HACCP records have been cleared. From this

moment on, any new generated HACCP alarm will be stored in position 1 of the alarm category to which

it belongs.

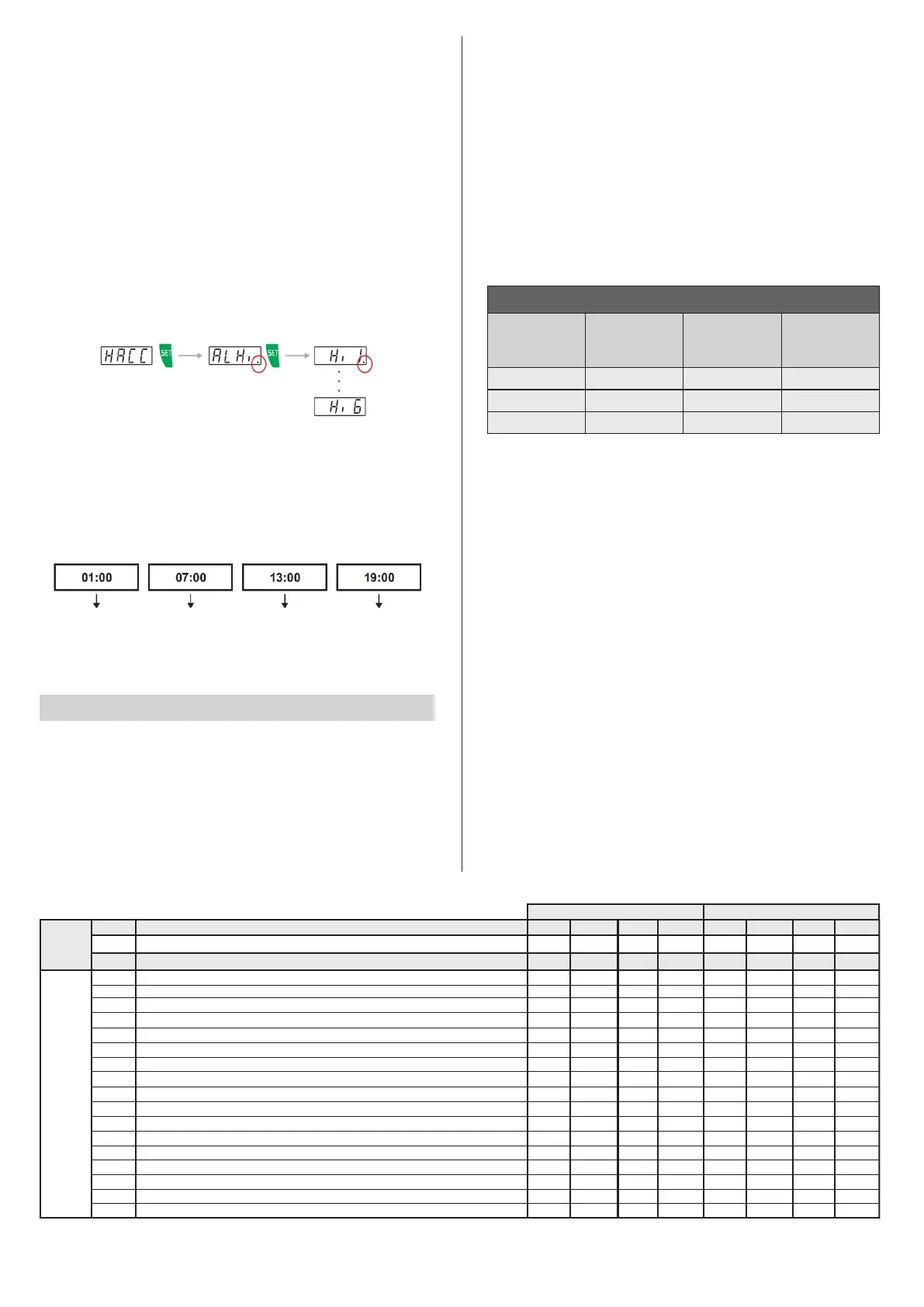

HACCP signaling

When a new HACCP alarm occurs, the indication (ccc) on the display will be lit. The indication will only

be cleared after this alarm is displayed in the [HACC]menu.

The facilitate viewing of new HACCP alarms, the dot in the lower right corner of the alarm type will be lit,

indicating which alarms have not yet been viewed, as shown in the figure below.

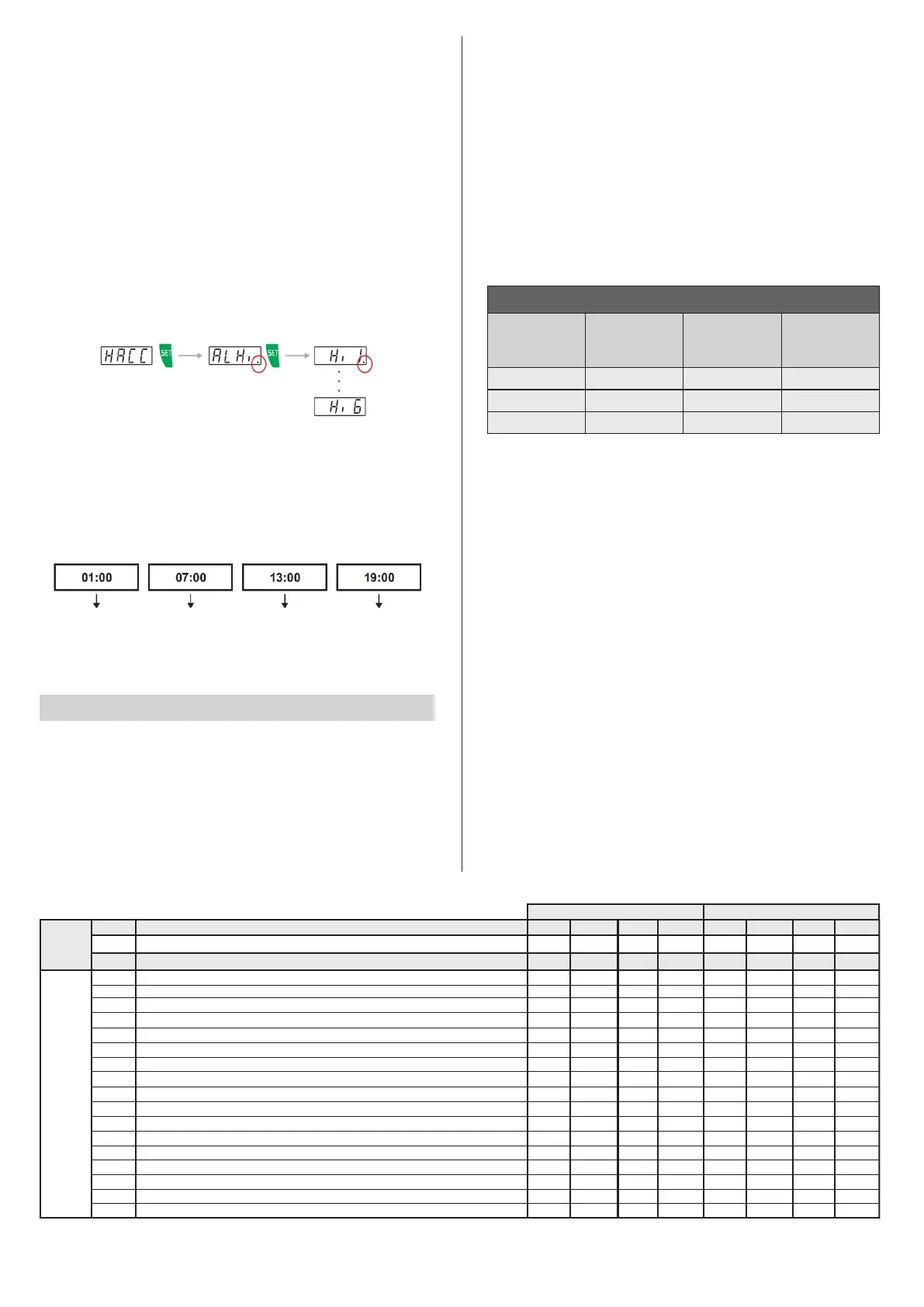

9.4.7 Scheduled Defrosting

You can configure the defrosting schedule to be equally distributed across the day by programming the

number of defrost cycles per day. To do this, you need to set the start of the defrosting as part of a

defrosting schedule, setting [F19] to 5, and configuring functions [F28] to [F37] to determine the

number of defrost cycles per day and their preferred times. With this, the defrost schedule makes it

possible to create a program from Monday to Friday, another program for Saturday and another for

Sunday. E.g. If the program for Monday to Friday consists of a preferred time of 1 pm (and the number of

defrosting cycles is 4, with an interval of 6 hours), the defrost schedule will be operate at 1:00 am, at 7:00

am, at 1:00 pm and 7:00 pm on each day.

9.4.8 Variable compressor control

The control settings of the variable compressor differ depending on the brand and model of the variable

compressor used. Consult the compressor’s technical manual.

In traditional cooling applications, the demand for using the compressor at full load is rare and restricted

to a few days a year. The control of the operating frequency of a variable capacity compressor adapts its

use to the real demand. This way, the compressor runs at a low speed most of the time, minimizing

energy consumption.

The operating frequency is proportional to the cooling capacity defined in parameters [F74] and

[F75]. The parameter [F76] defines the maximum operating frequency of the compressor and is

used in situations where it is needed to quickly lower the temperature of the controlled environment.

It is possible to keep the compressor operating continuously, keeping the temperature of the controlled

environment stable and reducing the number of compressor starts, thereby resulting in energy savings.

To use this characteristic, parameter [F82] - Variable compressor time on after reaching the setpoint

must be programmed.

9.4.9 Control PID

The PID controller is made up of a combination of three control actions: Proportional action (P), Integral

action (I) and Derivatice action (D). Each action receives a weighting (adjustable via parameters)

which represents a gain or adjustment time. This enables the PID to perform better when controlling

the process. Any control action is limited by the quality and capacity of the existing actuators in the

process.

P - Proportional gain (Pg) - The use of proportional action in a control system enables the difference

(error) between the desired output (reference, setpoint) and the current value of the process, to be

reduced. The proportional gain speeds up process’s response, however, the increased gains can

result in control oscillating.

I - Integral time (It) - The integral action has an energy storage function, which allows it to remove the

error between the reference and the output. It accumulates the error at a ‘’It’’ rate and attempts to

reduce it to zero. Low It values can cause the control to oscillate, however, long It times tend to slow

down the process Integral action must not be used on its own.

D - Derivative time (Dt) - The use of derivative action enables the process’s response time to be

increased and reduces oscillation, as it tries to anticipate the process’s behavior. Low values of Dt act

in a way to reduce the oscillatory anticipating the behavior of the process, however, high Dt values will

make the control very reactive, causing instability. Integral action must not be used on its own.

Obs.: Change the parameters individually, check the response and then modify another parameter. Proceed with

caution, to monitor the behavior of the process, analyze and modify the control parameters*. This guide is widely applied

in the technical literature on PID controllers, however processes with latency in their response may differ from the

indication in the table. The technician responsible for the process must correct small deviations manually. ** In specific

applications, the behavior can be reversed to that indicated.

SUMMARY TABLE - GENERAL GUIDANCE*

PID PARAMETER

OVERSHOOT

(peak, sobressinal)

STABILIZATION

TIME

(delay in stabilizing the

controller)

Increase KP**

Increase Little Effect Reduce

Increase Increase Null error

No effectReduce Reduce

Reduce Ti

Increase Td

ERROR

(the difference between

the setpoint and the

sensor)

9.5 Parameters Table

Min

Max

Standard Standard

Unit

Description

Fun

[,F00]

[CODE]

[,F01]

[,F02]

[,F03]

[,F04]

[,F05]

[,F06]

[,F07]

[,F08]

[,F09]

[,F10]

[,F11]

[,F12]

[,F13]

[,F14]

[,F15]

[,F16]

[,F17]

Min

Max

Unit

0

0

2

999

0

0

-9,0

0

0

0

0

2

999

°C

15,8

-

-

-

-

°C

°C

minutes

minutes

minutes

minutes

minutes

[,F04]

[,F04]

[,F04]

[,F04]

[,F04]

°F

°F

°F

[,F03]

[,F03]

[,F03]

-50,0

0,1

0,1

0,1

0,1

[,F03]

[,F03]

-4,0

-11,0

24,8

12,2

[,F04]

[,F04]

[,F03]

[,F03]

°C

°C

°C

°C

105,0

20,0

20,0

20,0

20,0

°C

°C

°C

°C

°F

°F

°F

°F

221,0

°F

°F

°F

°F

36,0

36,0

36,0

36,0

0,1

0,1

0,1

0,1

hh:mm

hh:mm

hh:mm

hh:mm

hh:mm

hh:mm

20,0

20,0

999

999

999

999

999

999

36,0

36,0

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

24:00(Off)

105,0

221,0

0,1

0,1

0(Off)

0(Off) 300

0(Off) 0(Off)0(Off)

minutes

0(Off)

0(Off)

0(Off)

-50,0

-58,0

-58,0

[,F04]

[,F03]

3,0

3,0

3,0

3,0

5,4

5,4

5,4

5,4

00:00

00:00

00:00

00:00

00:00

00:00

2,0

5,0

120

120

300

3,6

9,0

0,1

0,1

Controller operating mode

Access code: 123 (one hundred and twenty three)

Setpoint temperature

Desired temperature (economic setpoint)

Minimum desired temperature (setpoint) allowed to the user

Maximum desired temperature (setpoint) allowed to the user

Operating setpoint control differential (cooling)

Economic setpoint control differential (cooling)

Operating setpoint control differential (heating)

Economic setpoint control differential (heating)

Time for economic mode to begin (Monday to Friday)

Time for economic mode to begin (Saturday)

Time for economic mode to begin (Sunday)

Temperature difference (S3-S1) below which the economic setpoint is activated

Temperature difference (S3-S1) above which the economic setpoint is activated

Maximum temperature in economic mode

Fast Freezing temperature limit

Maximum fast freezing time

Delay time when powering up the controller

CELSIUS (°C)

FAHRENHEIT (°F)

COOLING / HEATING

MODO

MONDAY TO FRIDAY

DEFROST DEFROST DEFROST DEFROST

Loading...

Loading...