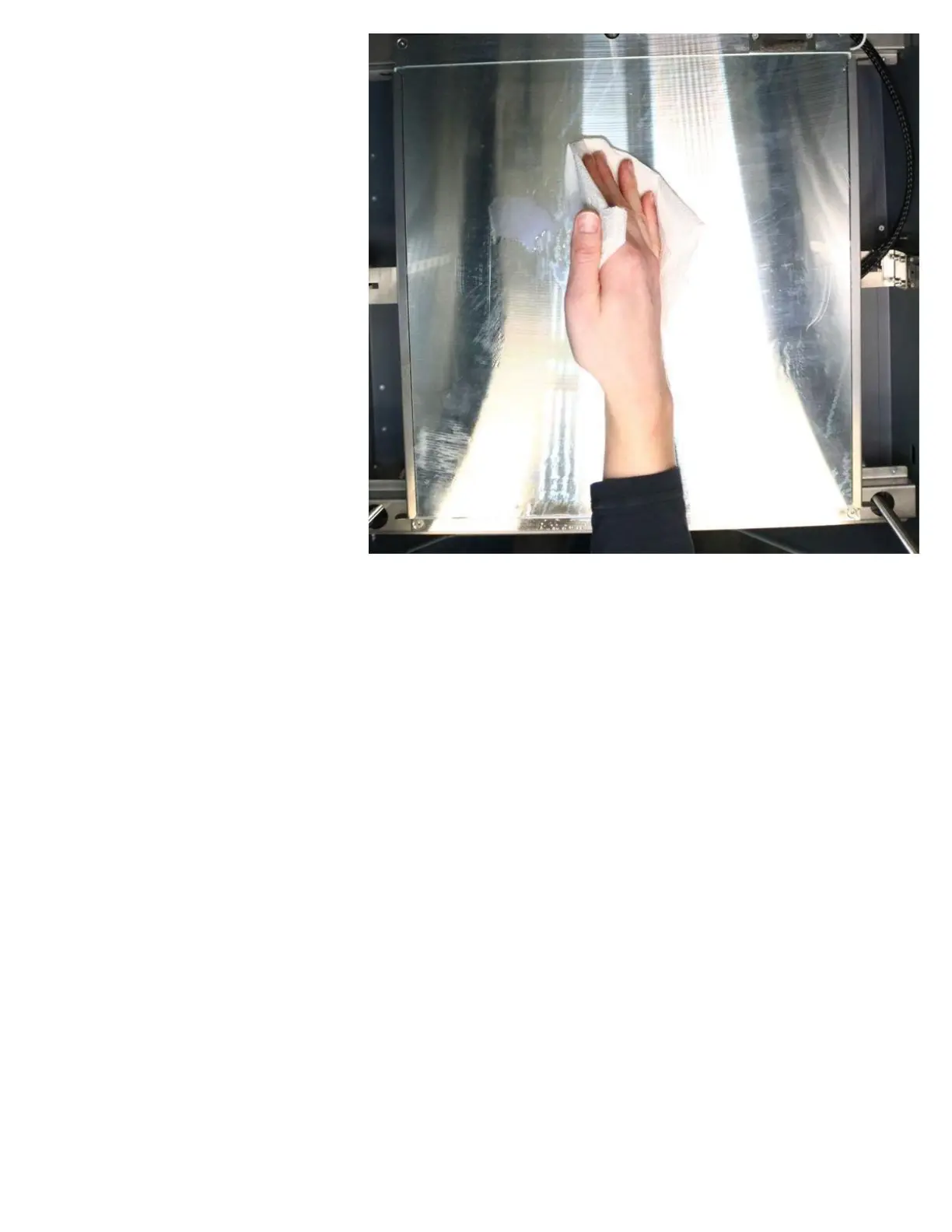

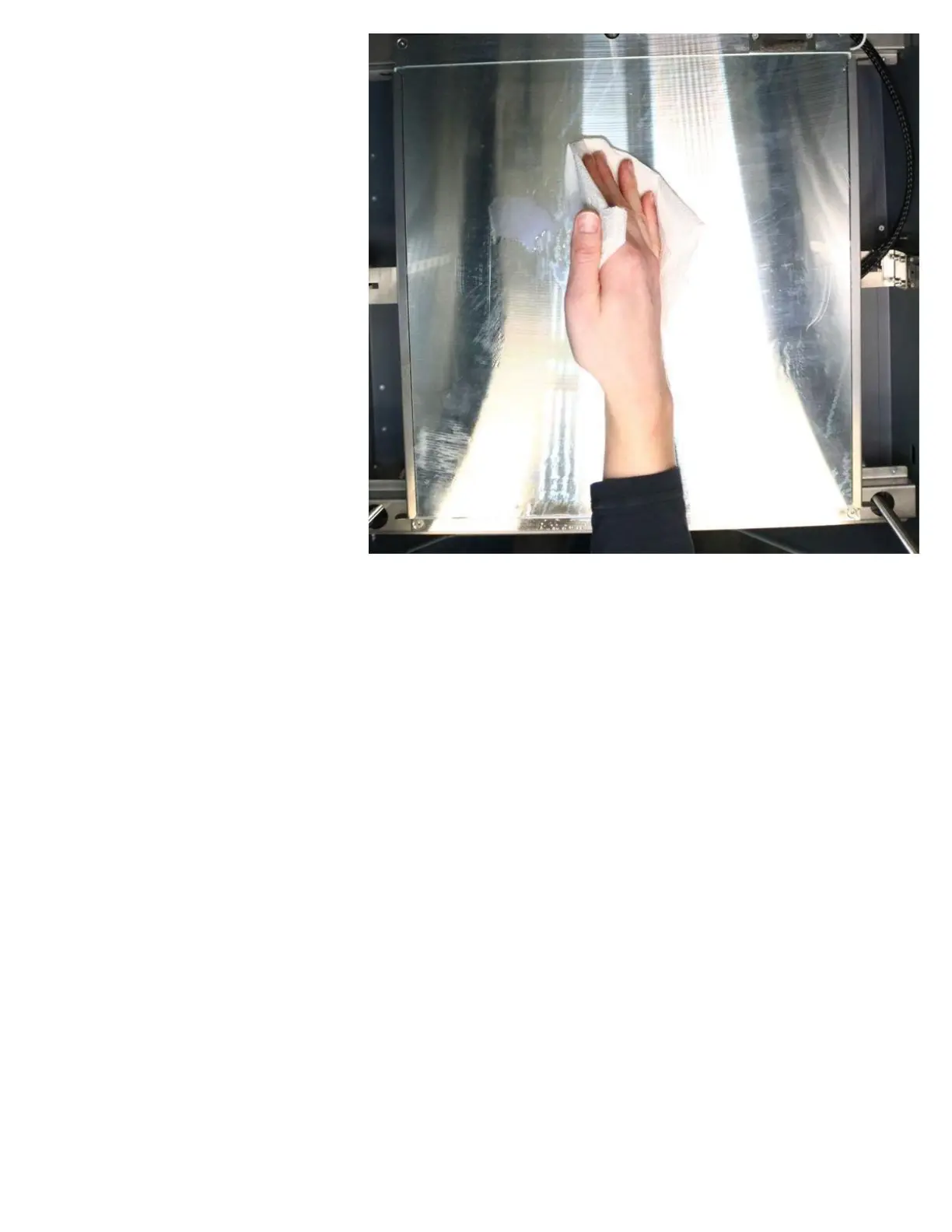

5. Collect the water and scraped-off

coating in a paper towel and wipe

it off the bed. Repeat as needed to

get all the coating and water off.

6. If desired, you can remove the

glass from the printer and clean it

separately, but the basic steps are

the same.

NOTE: If water gets between the

glass and the tool plate, it's a good

idea to remove the glass and wipe

it up. Over time, water can deposit

scale which is unsightly and can

prevent good heat transfer

between the tool plate and the

glass.

Preparing The Surface For Printing:

NOTE: The exact preparation you need will depend on what material you're printing. We're going

to cover the basics below, but if you have material-specific documentation that says something

different, follow those instructions.

General Notes:

- Surface must be clean

- Surface must be dry; wait for all water residue to evaporate off of the glass after cleaning

- Surface must be less than 45 C. Applying the bed coating with the surface hotter than this will lead to

poor first layer adhesion

Most materials will use 1 to 3 layers of purple gluestick applied to the glass.

1. Hold the gluestick at 90 degrees to the bed; it should stick straight up.

2. Apply only very light downward pressure during application; let the gluestick do the work.

3. Cover the area your print is going to need with back-and-forth passes with the gluestick, like a 3D printer

printing infill. You should have no gaps in your gluestick coverage.

Loading...

Loading...