13-8-619 Page 26

the oil change intervals planned accordingly by the user. Gardner Denver offers a free oil analysis

program with the AEON lubricants, and we recommend a sample be sent in at 100 hours on a new unit.

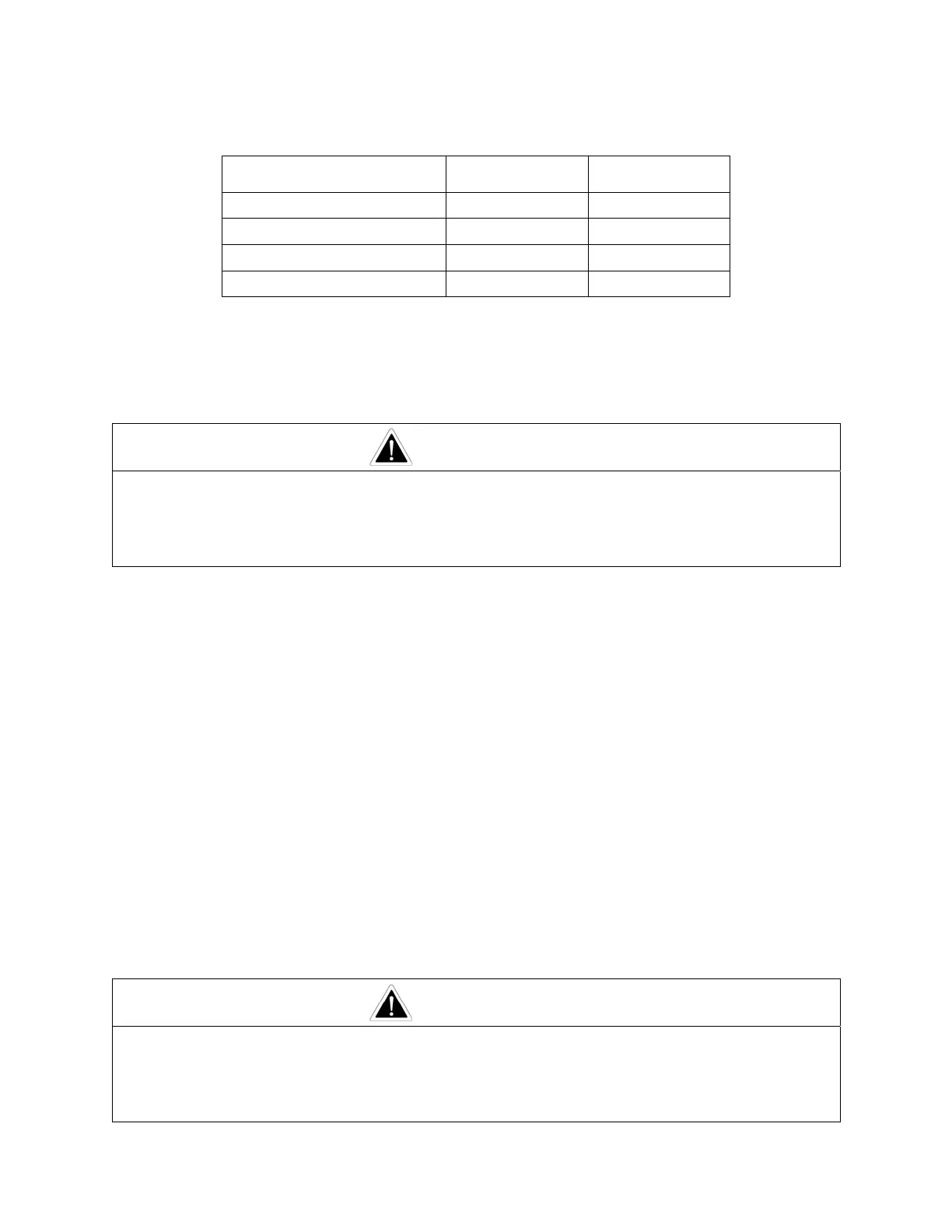

Discharge

Temperature

AEON 4000

Change Interval

AEON 9000SP

Change Interval

Up to 180° F (82° C)

4000 hrs. 8000 hrs.

180° to 190° F (82° to 88° C)

3000 hrs. 6000 hrs.

190° to 200° F (88° to 93° C)

2000 hrs. 4000 hrs.

200° F+ (93° C)

1000 hrs. 2000 hrs.

Figure 5-2 – OIL CHANGE INTERVAL

DRAINING AND CLEANING OIL SYSTEM

DANGER

Air/oil under pressure will cause severe personal injury or death. Shut down

compressor, relieve system of all pressure, disconnect, lockout and tagout

power supply to the starter before removing valves, caps, plugs, fittings, bolts

and filters.

Always drain the complete system. Draining when the oil is hot will help to prevent varnish deposits and

carry away impurities.

To drain the system, use one of the following methods:

1. Be sure the unit is completely off and that no air pressure is in the oil reservoir.

2. Disconnect, lockout and tagout the power supply to the starter.

3. Using the oil reservoir drain, empty the oil reservoir through the drain valve into a suitable container

group.

4. If the drained oil and/or the oil filter element are contaminated with dirt, flush the entire system:

reservoir, oil cooler, mixing valve and lines. Inspect the oil separator elements for dirt accumulation;

replace if necessary. If a varnish deposit exists, contact the factory for recommendations for

removal of the deposit and prevention of varnish.

FILLING OIL RESERVOIR

DANGER

Air/oil under pressure will cause severe personal injury or death. Shut down

compressor, relieve system of all pressure, disconnect, lockout and tagout

power supply to the starter before removing valves, caps, plugs, fittings, bolts

and filters.

Loading...

Loading...