USER GUIDE - MC3001

14

4 - MAINTENANCE

4.1 - MAINTENANCE:

4.1.1 - DIE LUBRICATION:

Friction on the dies whilst crimping is very important. For this reason, it is necessary to lubricate the bearing

surface of the die-carriers on the piston regularly. Indeed, an insufficiently lubricated machine could seize, or

the pistons and die-carriers could be subjected to increased wear.

To achieve correct lubrication, grease with a 60% concentration of molybdenum di-sulphide must be used

(this product is supplied with the machine and can be obtained from GATES, Part No. 7482-19227).

Lubricate every 100 crimping operations as follows:

-Shake the aerosol can, held upside down, for 1 minute (this amount of time is necessary for such a

thick product to be vaporised properly).

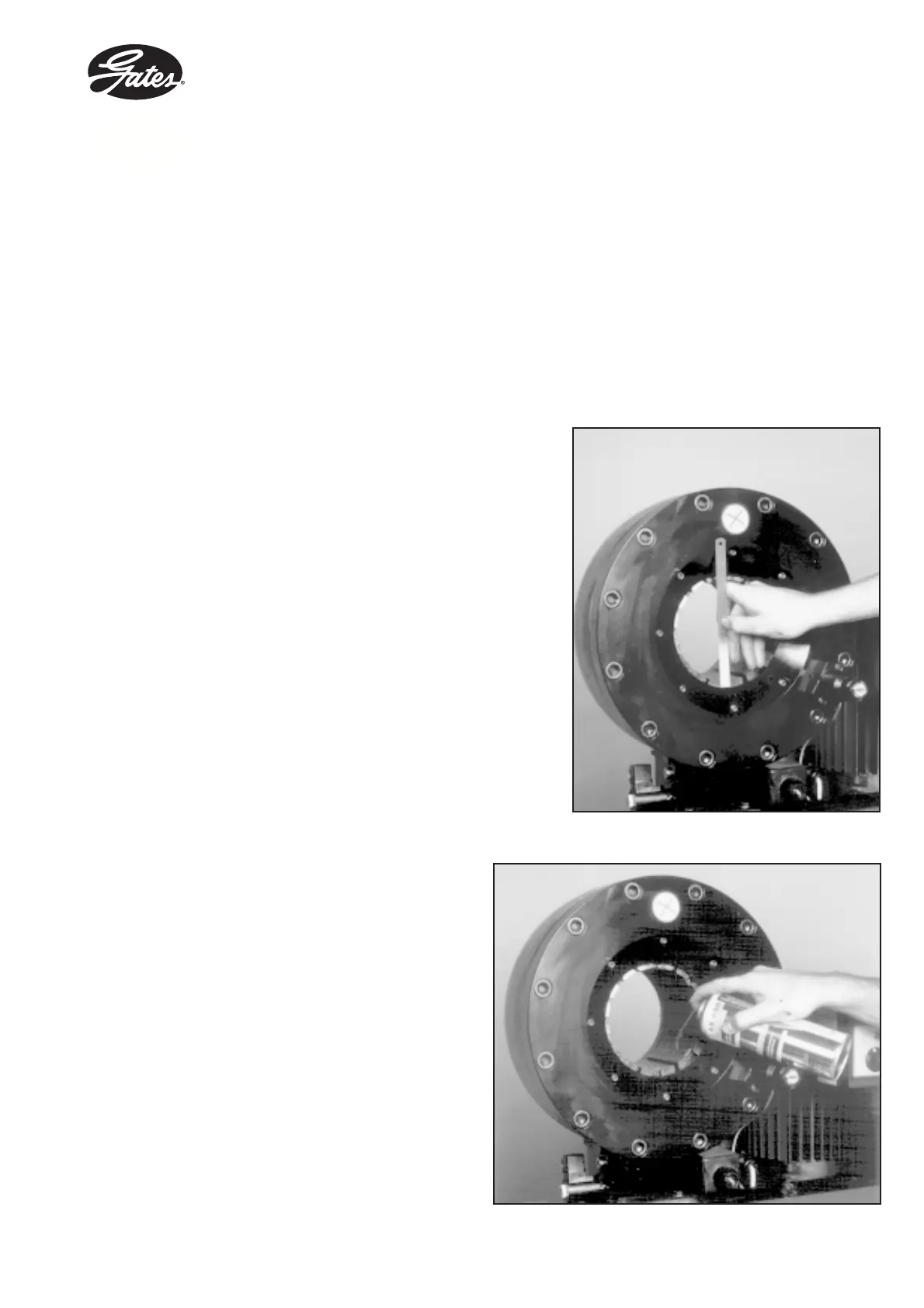

- Advance the die-carriers on the rapid cone. The die-carriers should be 5 mm above the face flange

(see figure 7).

Figure 7 :

Position of die-carriers for lubrication.

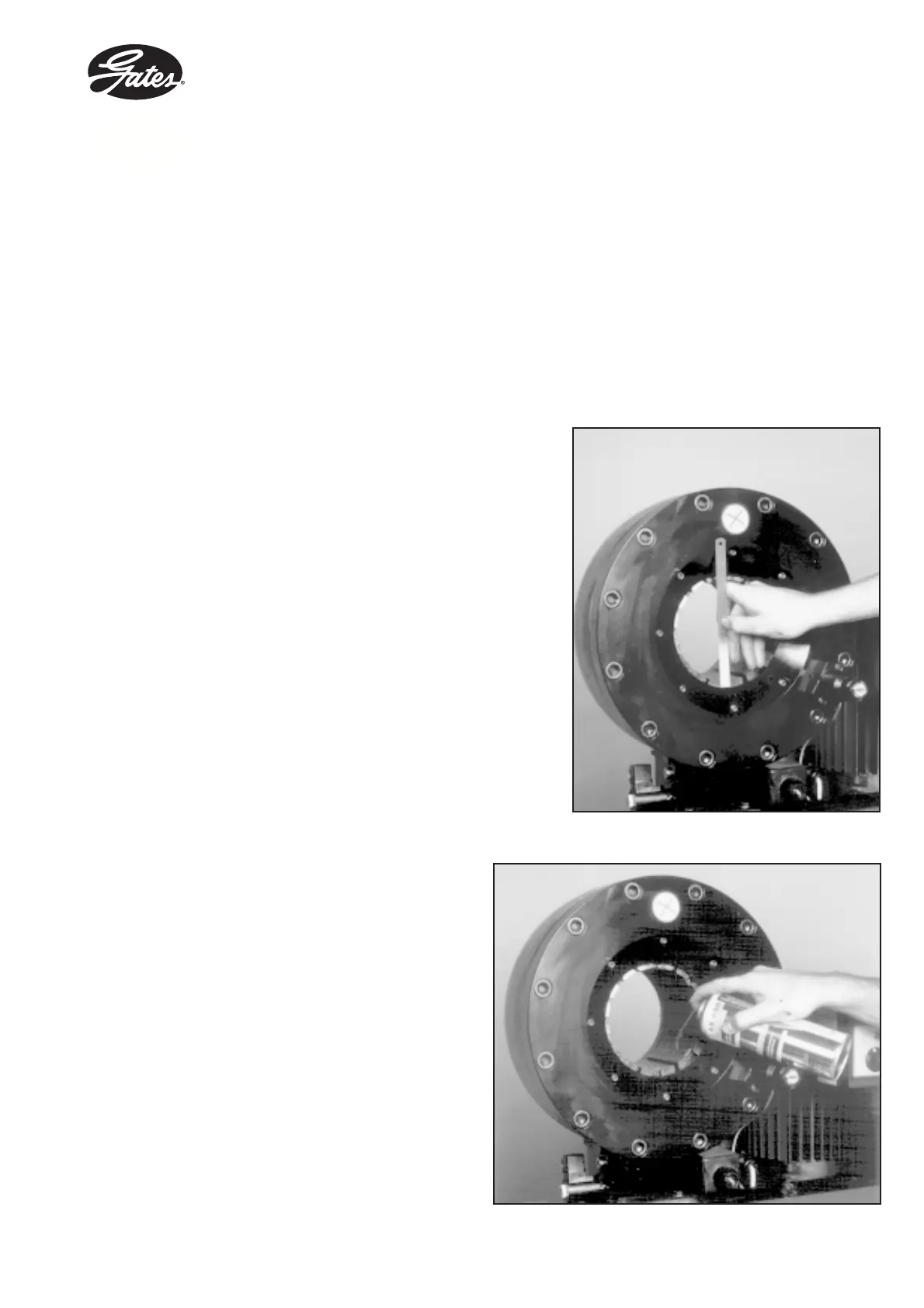

-Introduce the aerosol can plastic tube in the hole located at the rear of the die-carriers

(lubrication point N° 1 - see figure 8).

Figure 8 :

Lubrication point N° 1.

Recommended grease:

see above.

- Grease the piston through the holes of each die-carrier.

Loading...

Loading...