– 26 –

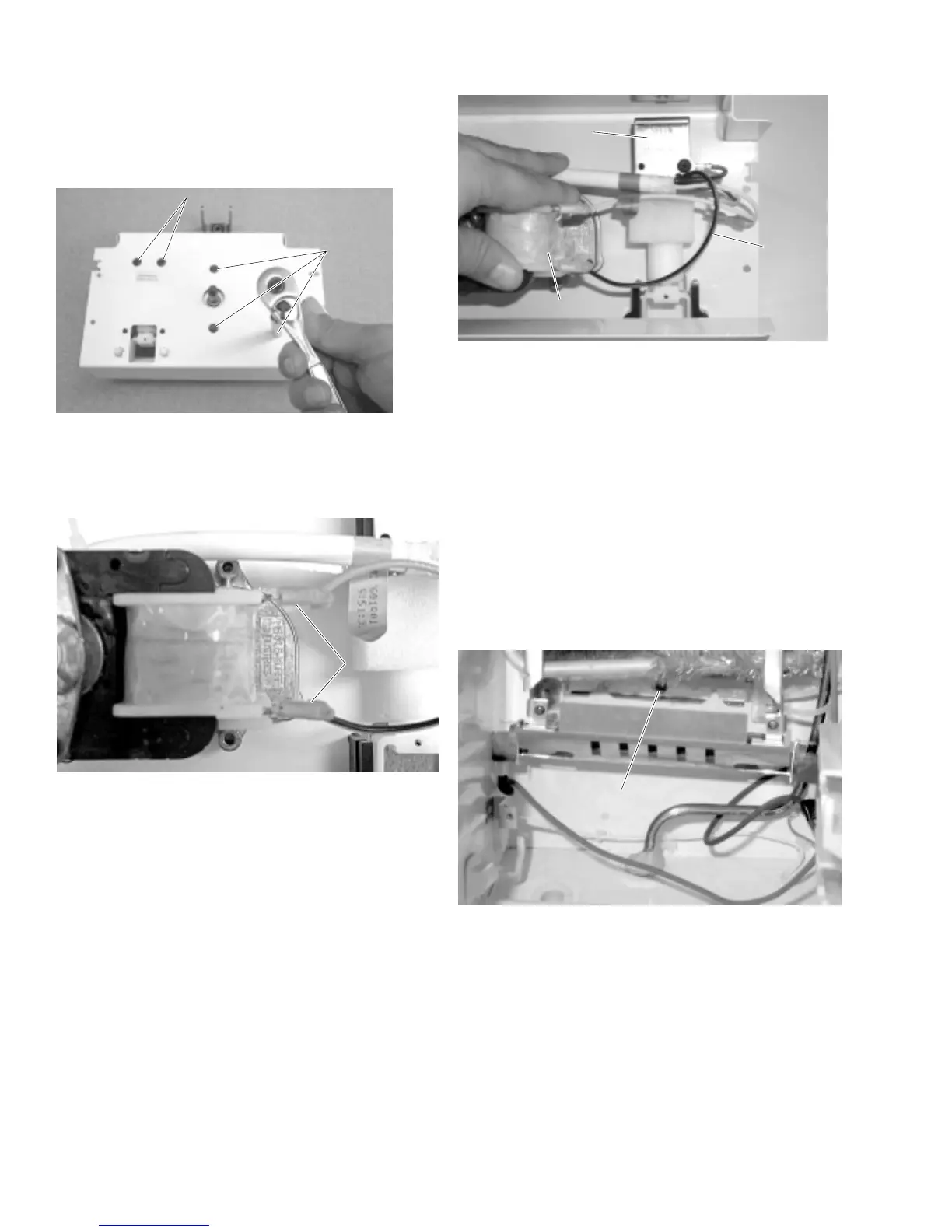

2. Remove 2 Phillips mounting screws.

3. Pull out the motor.

4. Disconnect the wire connectors.

5. Remove the drive fork and nut.

GEA00919

Solenoid Mounting ScrewsSolenoid Mounting Screws

Motor

Mounting

Screws

Motor

Mounting

Screws

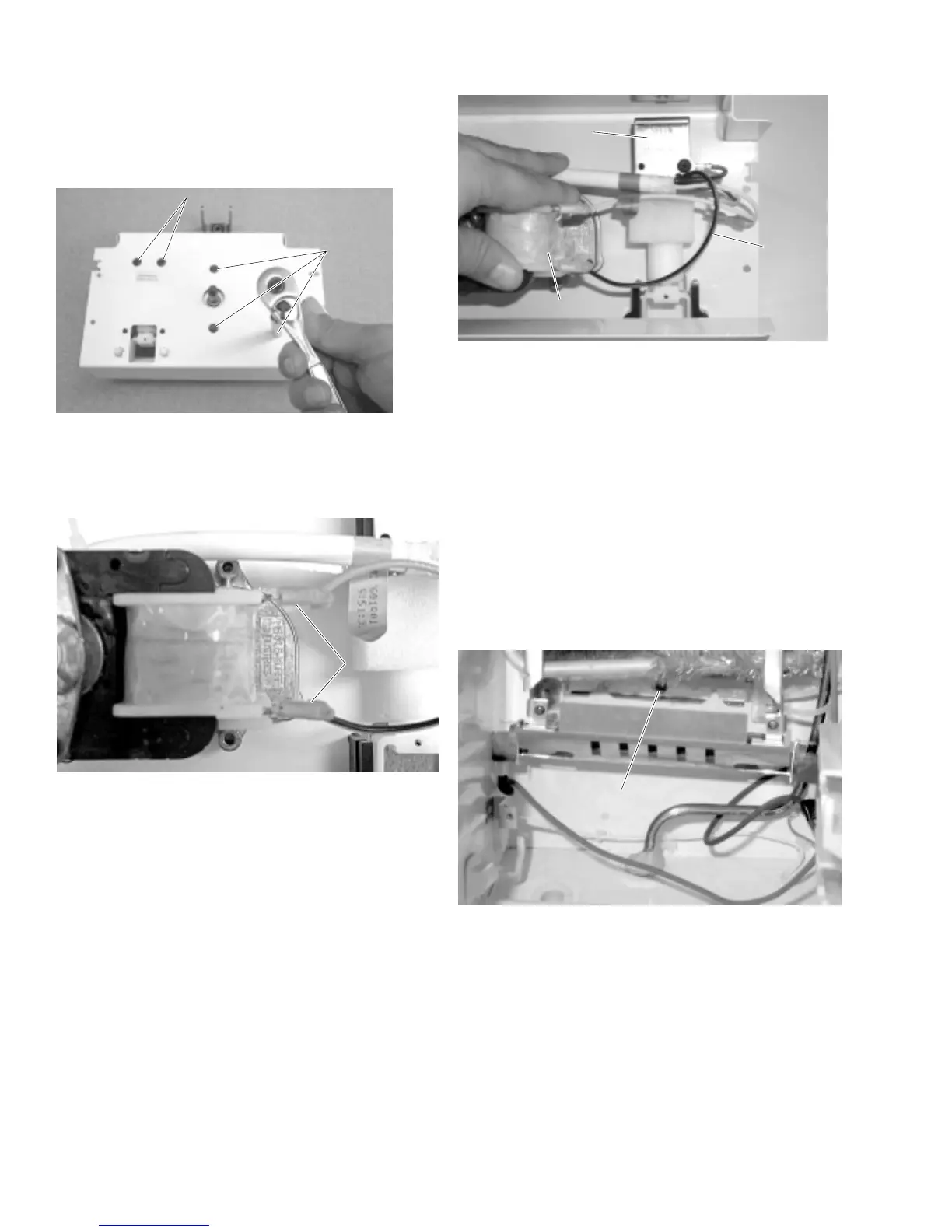

6. Disconnect the motor wiring connectors.

GEA00892

Wiring

Connectors

Wiring

Connectors

7. Remove 3 motor mounting screws.

8. Remove the motor from the housing.

Ice Cube Solenoid

The ice cube solenoid energizes when the cube

mode is selected on the dispenser control panel.

1. Remove the ice dispenser tray and assembly

(see page 21).

2. Remove 2 Phillips mounting screws.

3. Pull out the motor.

4. Disconnect the wire connectors.

5. Remove the ground wire to the ice cube

solenoid.

6. Disconnect the wire connectors.

GEA00695

Solenoid

Solenoid

Motor

Motor

Ground

Wire

Ground

Wire

7. Remove 2 solenoid mounting screws.

8. Slide the solenoid out of the housing.

Evaporator

Air is driven across the evaporator coils to

produce cold air for the freezer and fresh food

compartments. Evaporator is replace like previous

models.

1. Complete steps 4 and 5 in the

Evaporator

Fan

procedure.

GEA00893

ScrewScrew

2. Remove 3 Phillips screws from the evaporator

mounting.

3. Cut the capillary and suction line.

4. Remove the evaporator.

Loading...

Loading...