– 31 –

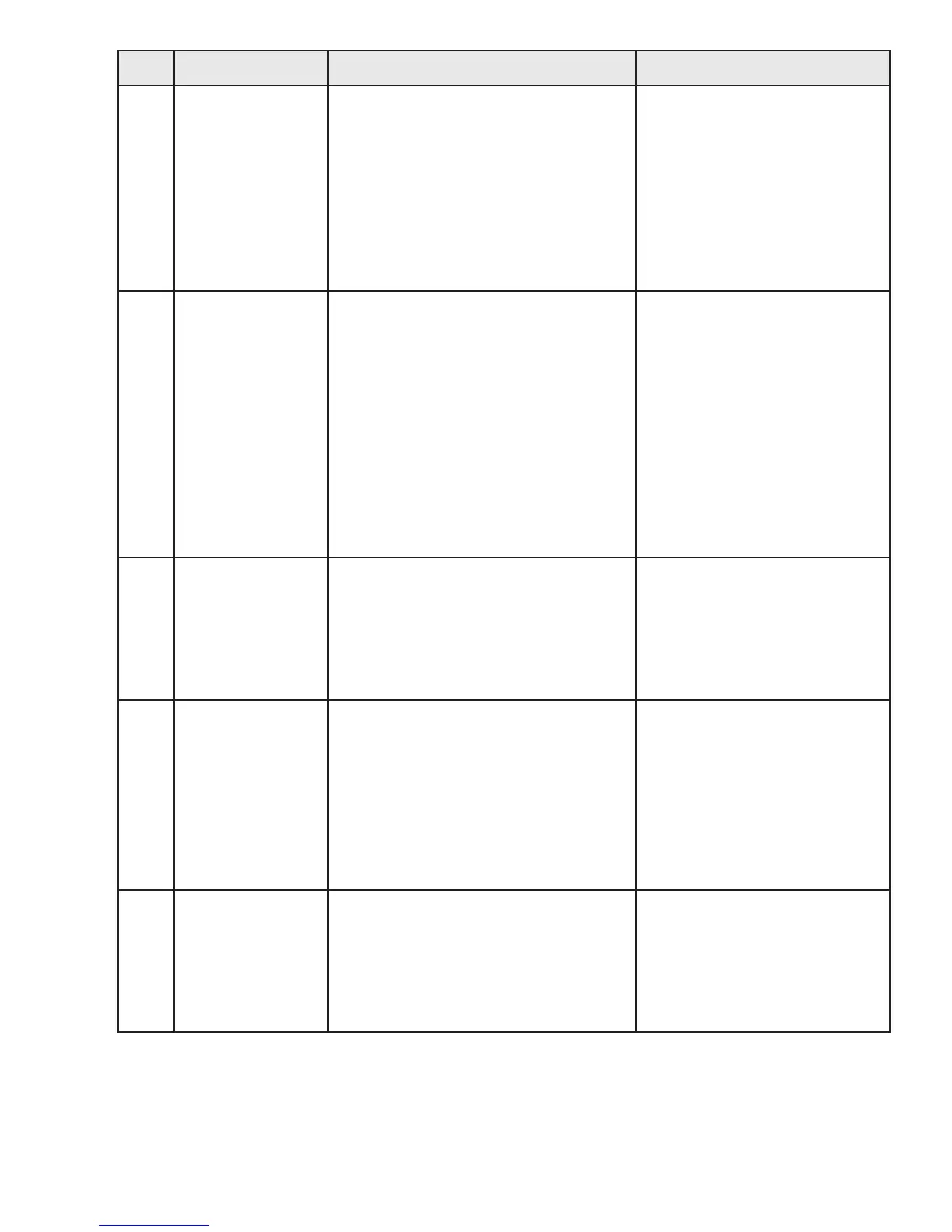

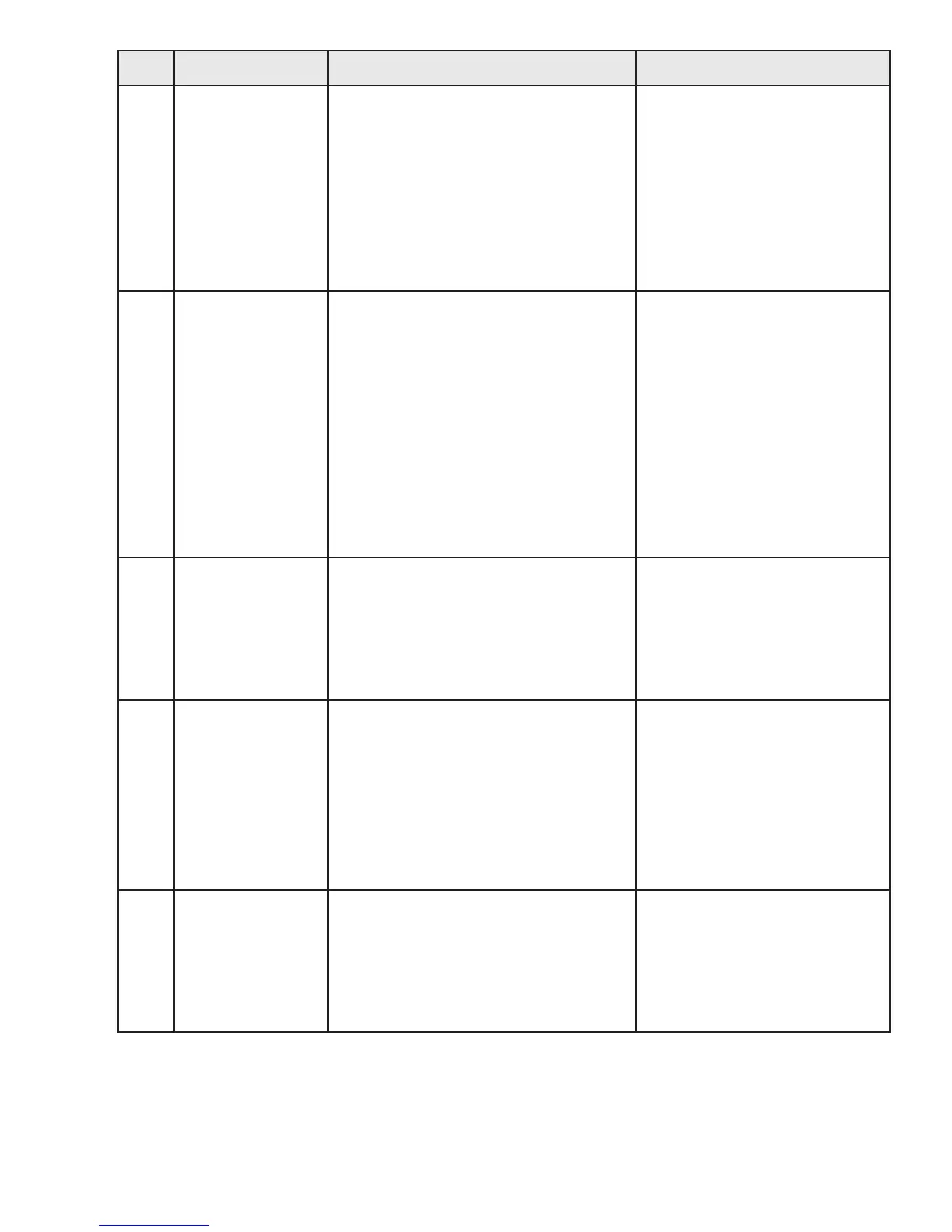

Fault

Code

Fault Name Description Repair Action

20 Critical Flood Level

by Gallons

Water volume into the tub exceeded 41

gallons as calculated by the control.

1. Pressure tube is momentarily pinched,

KDVZDWHULQLWSDUWLDOEORFNDJHLIÀRRG

Fault 12 occurs.

2. /RZZDWHUSUHVVXUHÀRZRUSHUPDQHQW

SUHVVXUHV\VWHPEORFNDJHLI12ÀRRG

Fault 12 occurs.

Check pressure tube for

pinches where it goes through

top cover grommet.

Check pressure tube for

trapped water.

Check for any leaking water

valves.

Check home water pressure.

Check the output voltage from

the pressure sensor to ensure

it matches the water level in

the basket according to the

pressure sensor chart.

21 Flood Warning Level

by Gallons.

Water volume into the tub exceeded 36.3

gallons as calculated by the control. Stops

¿OOLQJ

1. Pressure tube is momentarily pinched

or has water in it, partial blockage if

Flood fault 6, 7, or 12 occurs.

2. /RZZDWHUSUHVVXUHÀRZRUSHUPDQHQW

SUHVVXUHV\VWHPEORFNDJHLI12ÀRRG

Fault 6, 7, or 12 occurs.

Check pressure tube for

pinches where it goes through

top cover grommet.

Check pressure tube for

trapped water.

Check for any leaking water

valves.

Check home water pressure.

Check the output voltage from

the pressure sensor to ensure

it matches the water level in

the basket according to the

pressure sensor chart. If it

does not, the control will need

to be replaced as the pressure

sensor is mounted directly to

the control.

22 Out of Balance

(OOB) during Dry

Load Sense.

Large wet/OOB load being washed. This is

set if OOB condition is detected during dry

load sense algorithm. Dry load sense will

be abandoned and wet load sense will be

started.

1. Check for excessively OOB

load. Customer Education on

how to distribute load.

2. Check the basket for excessive

friction or for being excessively

out of round. Basket should

spin freely and without wobble.

If friction is found, remove it. If

basket is bad, replace it.

23 Critical Lid Lock 1. Lock blockage

2. Lid Lock fault. Will not lock or unlock or

is locked while lid is opened.

Verify that the lid lock is not

blocked by any external debris.

Check lid switch continuity at

J513 on the control.

Check continuity of lid lock

position. Opened or Closed.

Check for proper operation

of lid lock. 120 VAC while

activating.

Check lid lock wiring harness

from the control to lock

assembly.

24 Lid Logic Failure Lid switch fault.

This fault is set if the system perceives the

lid to be both OPEN and LOCKED for 5

consecutive seconds

1. Check harness and

connections from the control

to the lid lock assembly for

damage and continuity.

2. Run a spin cycle. Pull up on

the lid during spin for more

than 5 seconds and see if this

fault occurs. Replace lid lock

assembly.

(Continued next page)

Loading...

Loading...