Maintenance

Maintenance plan

GE Information08- 2016 L51- 004EN/07

6/8

Detail of maintenance operations, continued

SF

6

pressure gas

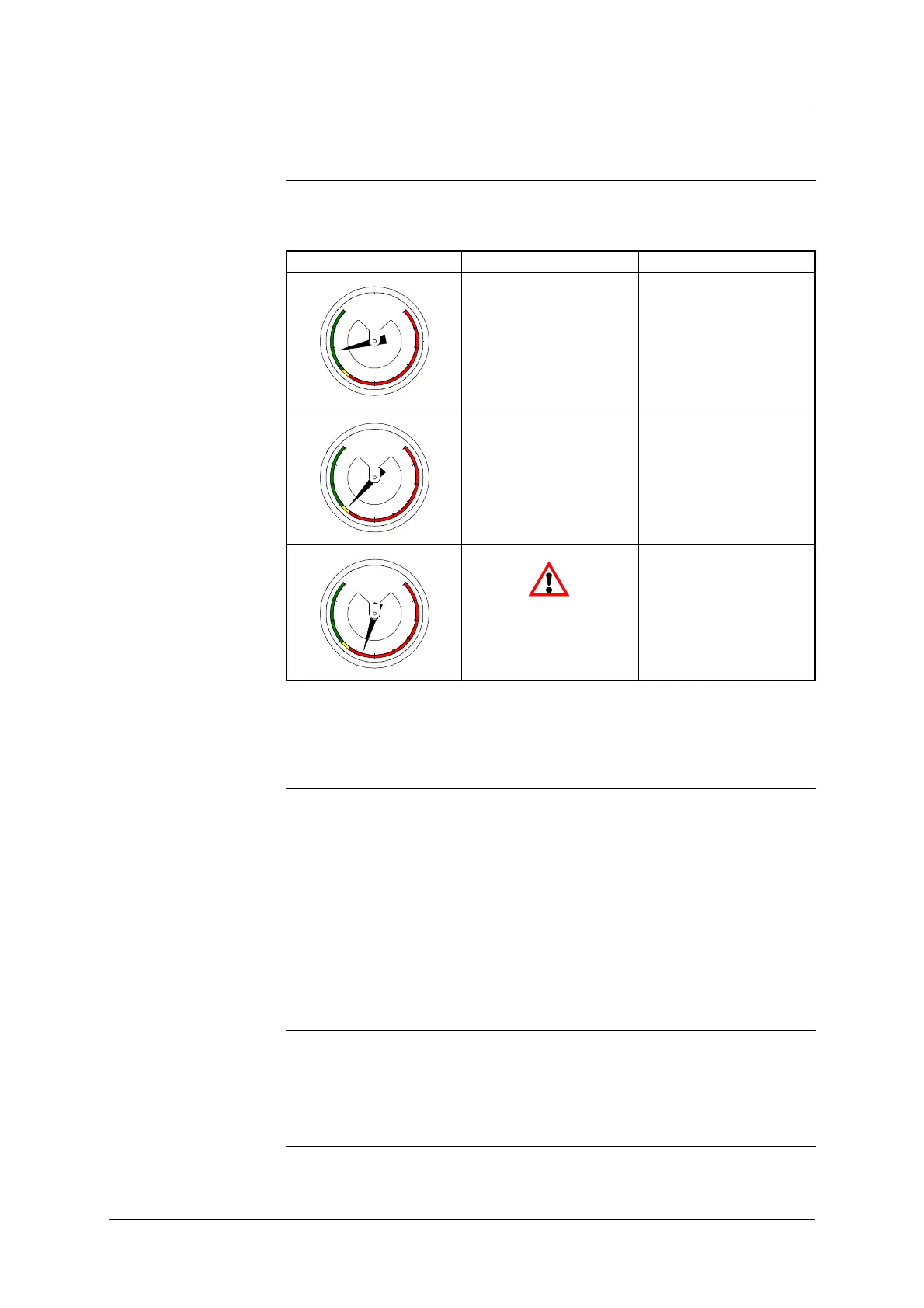

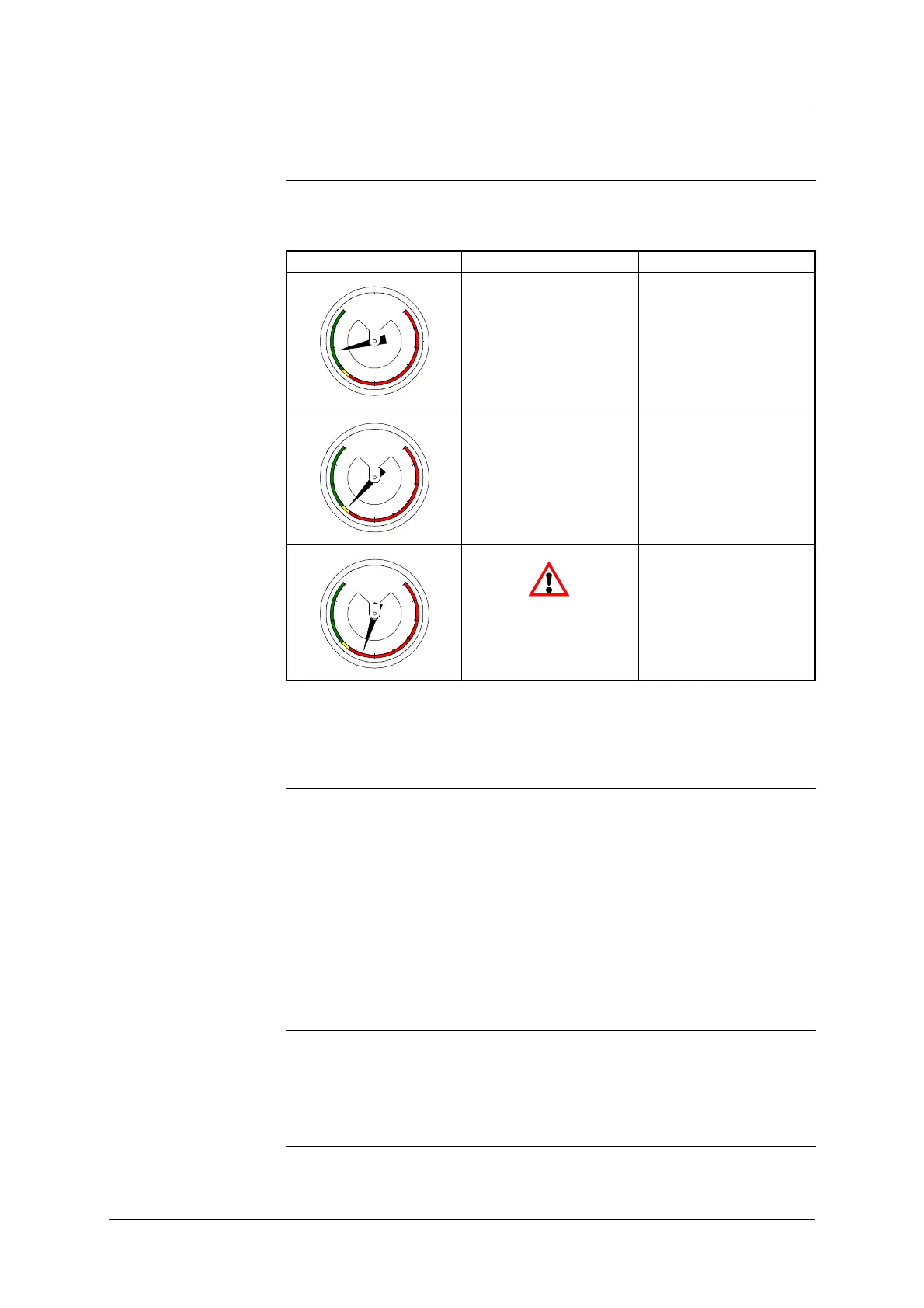

For a circuit- breaker equipped with a ”dial- type” SF

6

gas densimeter, check

the position of the needle.

Needle position Colored area Direction

GREEN None

YELLOW

Perform a topping- up

operation.

RED

Abnormally low density,

find the origin of the

leak and contact

Grid Solutions

After- sales Service.

NOTE: If the intersection is in either the yellow or red zone, without

any particular indication from the electrical contact densimeter, verify

the concordance of different information sources to find the defective

element and then replace it.

Operating device

Air- vents should be clean, free of dust and unobstructed. If necessary clean

using a solvent.

Make sure that the permanent resistors are working properly by checking that

these give off heat and that there are no overheating marks (a zone notorious

for this).

For thermally controlled resistors, check that energizing and de- energizing

takes place correctly at voltage supply terminals by means of a thermostat

(recommended thermostat temperature: +5_C.

If necessary, change resistors found to be defective.

For the opening damper , if any leak is observed, please contact

Grid Solutions, After- Sales Department, to proceed with any changes

Operation counter

Read indications given by the counter(s) and note these on the inspection

sheet ”Maintenance visits”.

The number of circuit- breaker operations recorded influences future

maintenance operations.

Continued on next page.

Loading...

Loading...