5-252 L60 Line Phase Comparison System GE Multilin

5.7 INPUTS/OUTPUTS 5 SETTINGS

5

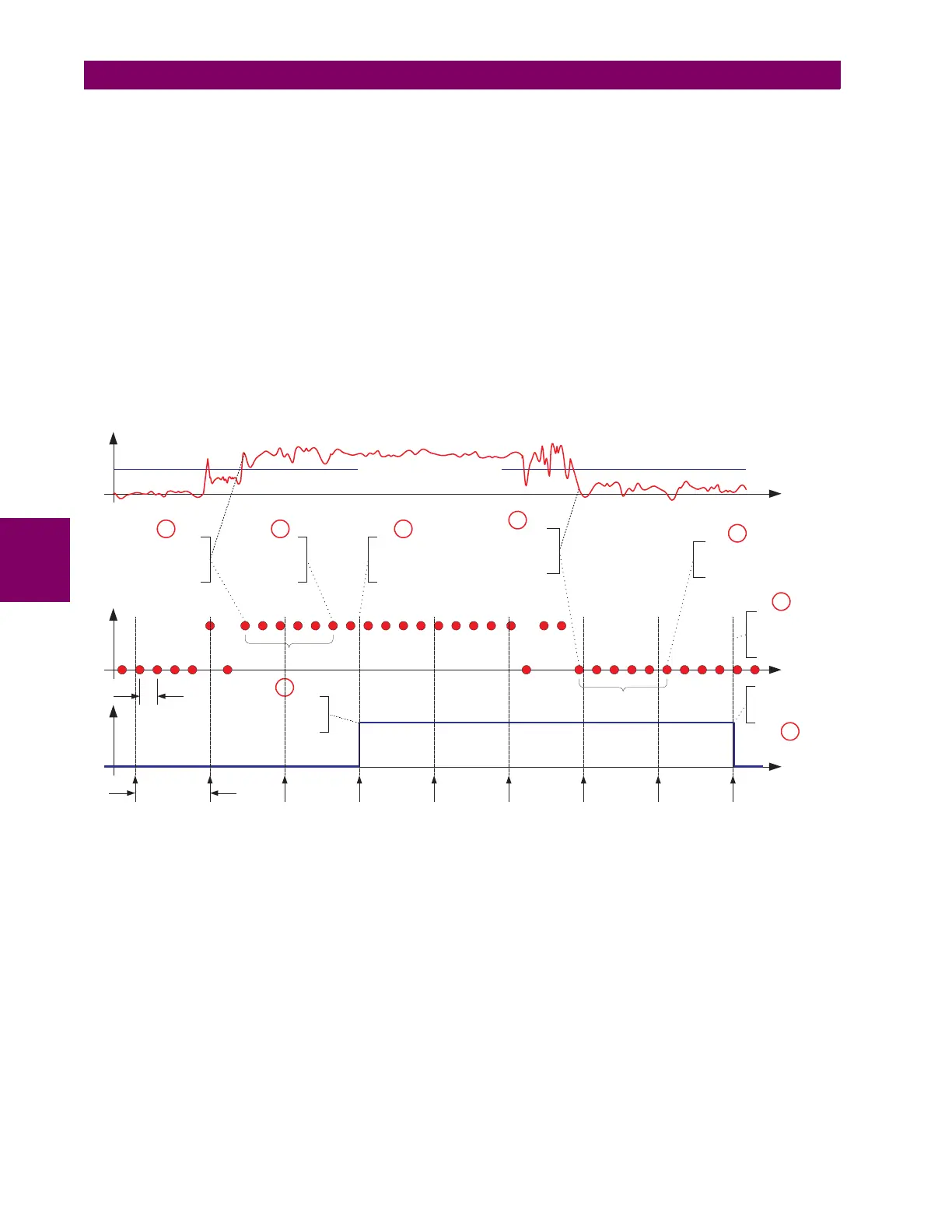

The FlexLogic™ operand response time to the contact input change is equal to the debounce time setting plus up to one

protection pass (variable and depending on system frequency if frequency tracking enabled). If the change of state occurs

just after a protection pass, the recognition is delayed until the subsequent protection pass; that is, by the entire duration of

the protection pass. If the change occurs just prior to a protection pass, the state is recognized immediately. Statistically a

delay of half the protection pass is expected. Owing to the 0.5 ms scan rate, the time resolution for the input contact is

below 1msec.

For example, 8 protection passes per cycle on a 60 Hz system correspond to a protection pass every 2.1 ms. With a con-

tact debounce time setting of 3.0 ms, the FlexLogic™ operand-assert time limits are: 3.0 + 0.0 = 3.0 ms and 3.0 + 2.1 = 5.1

ms. These time limits depend on how soon the protection pass runs after the debouncing time.

Regardless of the contact debounce time setting, the contact input event is time-stamped with a 1 μs accuracy using the

time of the first scan corresponding to the new state (mark no. 2 below). Therefore, the time stamp reflects a change in the

DC voltage across the contact input terminals that was not accidental as it was subsequently validated using the debounce

timer. Keep in mind that the associated FlexLogic™ operand is asserted/de-asserted later, after validating the change.

The debounce algorithm is symmetrical: the same procedure and debounce time are used to filter the LOW-HIGH (marks

no.1, 2, 3, and 4 in the figure below) and HIGH-LOW (marks no. 5, 6, 7, and 8 below) transitions.

Figure 5–136: INPUT CONTACT DEBOUNCING MECHANISM AND TIME-STAMPING SAMPLE TIMING

Contact inputs are isolated in groups of four to allow connection of wet contacts from different voltage sources for each

group. The

CONTACT INPUT THRESHOLDS determine the minimum voltage required to detect a closed contact input. This

value should be selected according to the following criteria: 17 for 24 V sources, 33 for 48 V sources, 84 for 110 to 125 V

sources and 166 for 250 V sources.

For example, to use contact input H5a as a status input from the breaker 52b contact to seal-in the trip relay and record it in

the Event Records menu, make the following settings changes:

CONTACT INPUT H5A ID: "Breaker Closed (52b)"

CONTACT INPUT H5A EVENTS: "Enabled"

Note that the 52b contact is closed when the breaker is open and open when the breaker is closed.

842709A1.cdr

DEBOUNCE TIME

(user setting)

At thistime, the

new (HIGH)

contact state is

validated

The FlexLogic

TM

operand is going to

be asserted at this

protection pass

The FlexLogic

TM

operand

changes reflecting the

validated contact state

Timestamp ofthefirst

scan corresponding to

thenewvalidated state is

logged intheSOErecord

2 1 3

4

DEBOUNCE TIME

(user setting)

At thistime, thenew

(LOW) contact state is

validated

The FlexLogic

TM

operand is going to be

de-asserted at this

protection pass

The FlexLogic

TM

operand

changes reflecting the

validated contact state

5

7

8

Timestamp ofthefirst

scan corresponding to the

newvalidated state is

logged intheSOErecord

6

SCAN TIME

(0.5 msec)

PROTECTION PASS

(8times a cycle controlled by the

frequency trackingmechanism)

RAW CONTACT

STATE

FLEXLOGIC

TM

OPERAND

INPUT

VOLTAGE

USER-PROGRAMMABLE THRESHOLD

Loading...

Loading...