D

GB

F

E

I

Ru

13

96178-06.2015-DGbFEIRu

4| Compressor assembly

4.4 Pipes

Pipesandsystemcomponentsmustbecleananddryinsideandfreeofscale,swarfandlayersof

rustandphosphate.Onlyuseair-tightparts.

Laypipes correctly. Suitable vibration compensators must be providedto prevent pipes being

crackedandbrokenbyseverevibrations.

Ensureaproperoilreturn.

Keeppressurelossestoanabsoluteminimum.

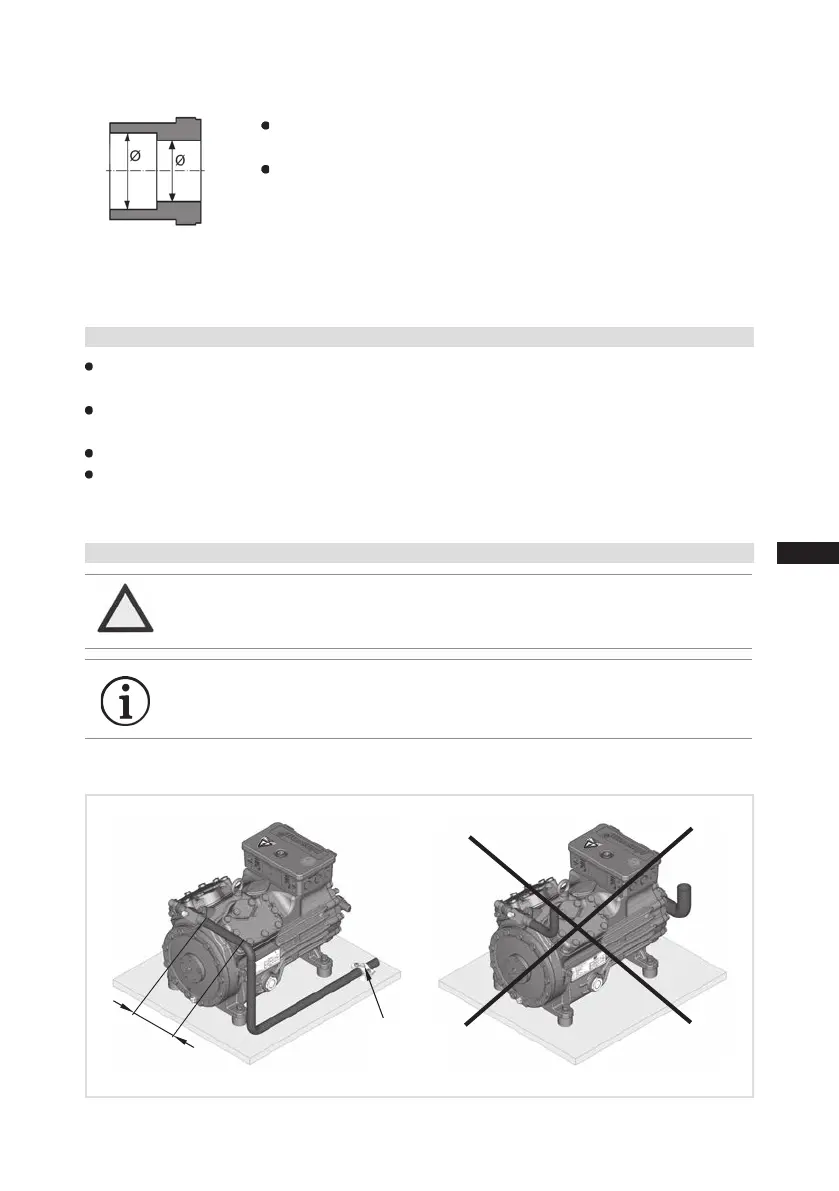

The pipe connectionshavegraduatedinsidediameterssothatpipeswith

standartmillimetreandinchdimensionscanbeused.

Theconnectiondiametersoftheshut-offvalvesareratedformaximum

compressoroutput.Theactualrequiredpipecrosssectionmustbe

matched to the output. The same applies for non-return valves.

Fig.16:graduated

internaldiameter

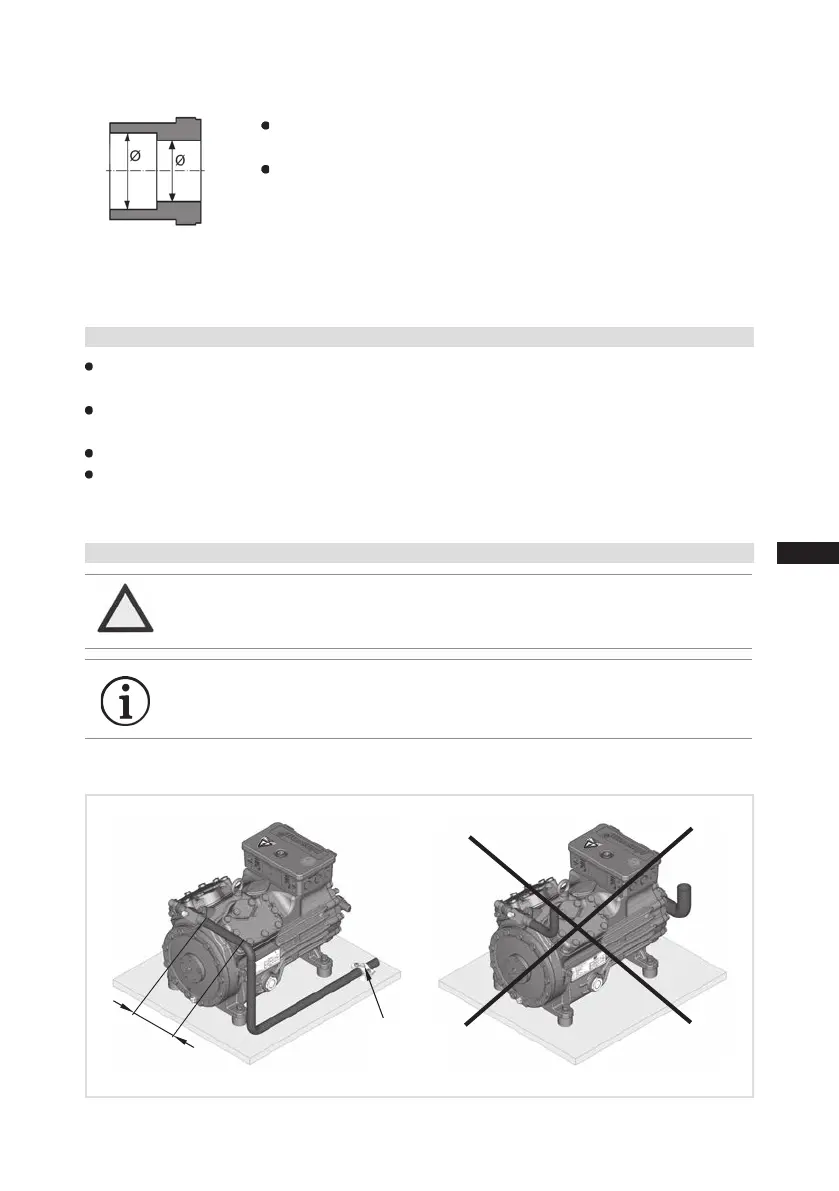

Fig.17

Rigid

fixed point

As short as

possible

4.5 Laying suction and pressure lines

A rule of thumb:Alwayslaytherstpipesectionstartingfromtheshut-offvalvedownwards and

parallel to the drive shaft.

ATTENTION Improperly installed pipes can cause cracks and tears, the result

being a loss of refrigerant.

INFO Proper layout of the suction and discharge lines directly after

the compressor is integral to the system’s smooth running and

vibration behaviour.

Loading...

Loading...