26

D

GB

F

E

I

Ru

96178-06.2015-DGbFEIRu

7.1 Preparation

7.2 Work to be carried out

7| Maintenance

Inordertoguaranteeoptimumoperationalreliabilityandservicelifeofthecompressor,we recommend

carryingoutservicingandinspectionworkatregularintervals:

Oil change:

- notmandatoryforfactory-producedseriessystems.

- foreldinstallationsorwhenoperatingneartheapplicationlimit:forthersttimeafter100

to 200 operating hours,thenapprox. every3 years or 10,000 - 12,000 operating hours.

Disposeofusedoilaccordingtotheregulations;observenationalregulations.

Annual checks: Oil level, leak tightness, running noises, pressures, temperatures, function of

auxiliarydevicessuchasoilsumpheater,pressureswitch.

6.8 Connection of oil level regulator

Theconnection"O"isprovidedforinstallinganoillevelregulator.Acorrespondingadaptermustbe

obtainedfromthetrade.

6| Commissioning

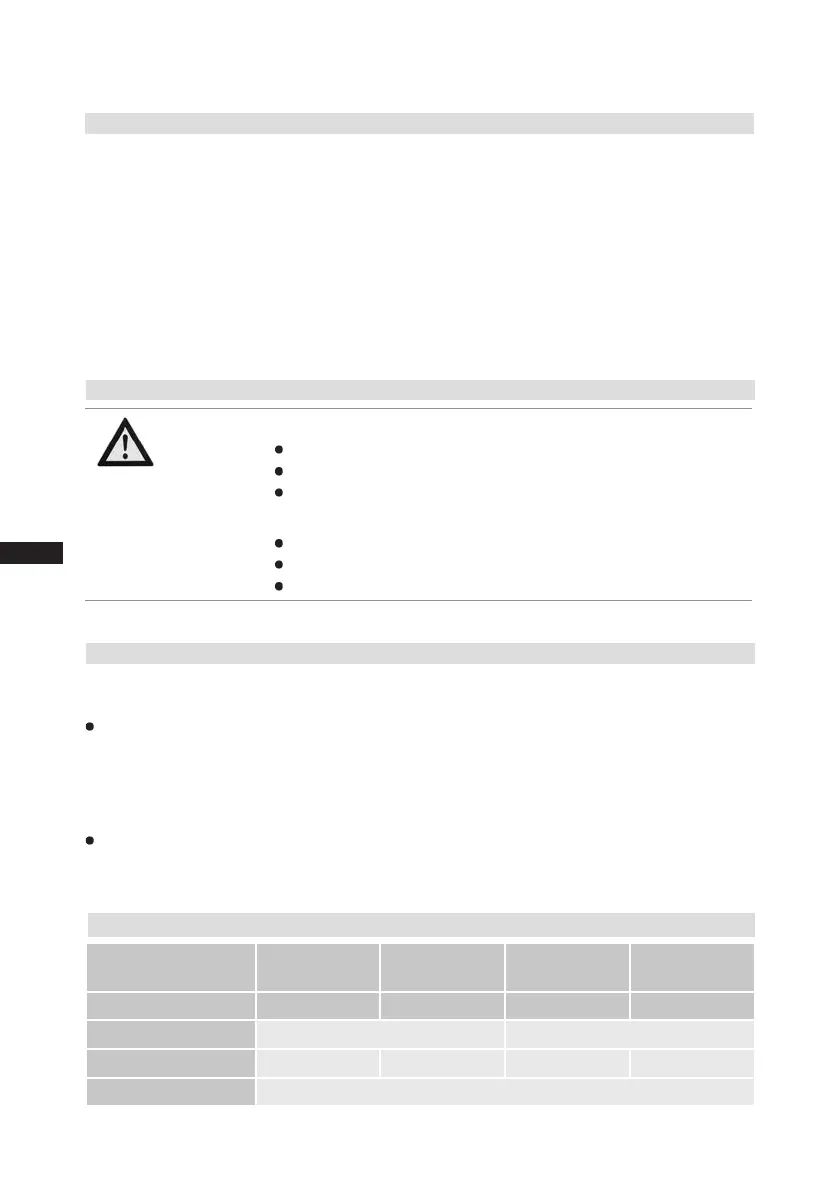

Only use genuine GEA Bock spare parts!

7.3 Spare parts recommendation

HG34e / ...

215-4(S)

255-4(S)

315-4(S)

380-4(S)

215-4SR407C

255-4SR407C

315-4SR407C

380-4SR407C

Designation

Ref. No. Ref. No. Ref. No. Ref. No.

Setofgaskets 08534 80367

Valveplatekit 80305 80306 80305 80306

Oilpumpkit 08324

WARNING Before starting any work on the compressor:

Switch off the compressor and secure it to prevent a restart.

Relieve compressor of system pressure.

Preventairfrominltratingthesystem!

After maintenance has been performed:

Connect safety switch.

Evacuate compressor.

Release switch lock.

Loading...

Loading...