26

D

GB

F

E

09726-06.2018-DGbF

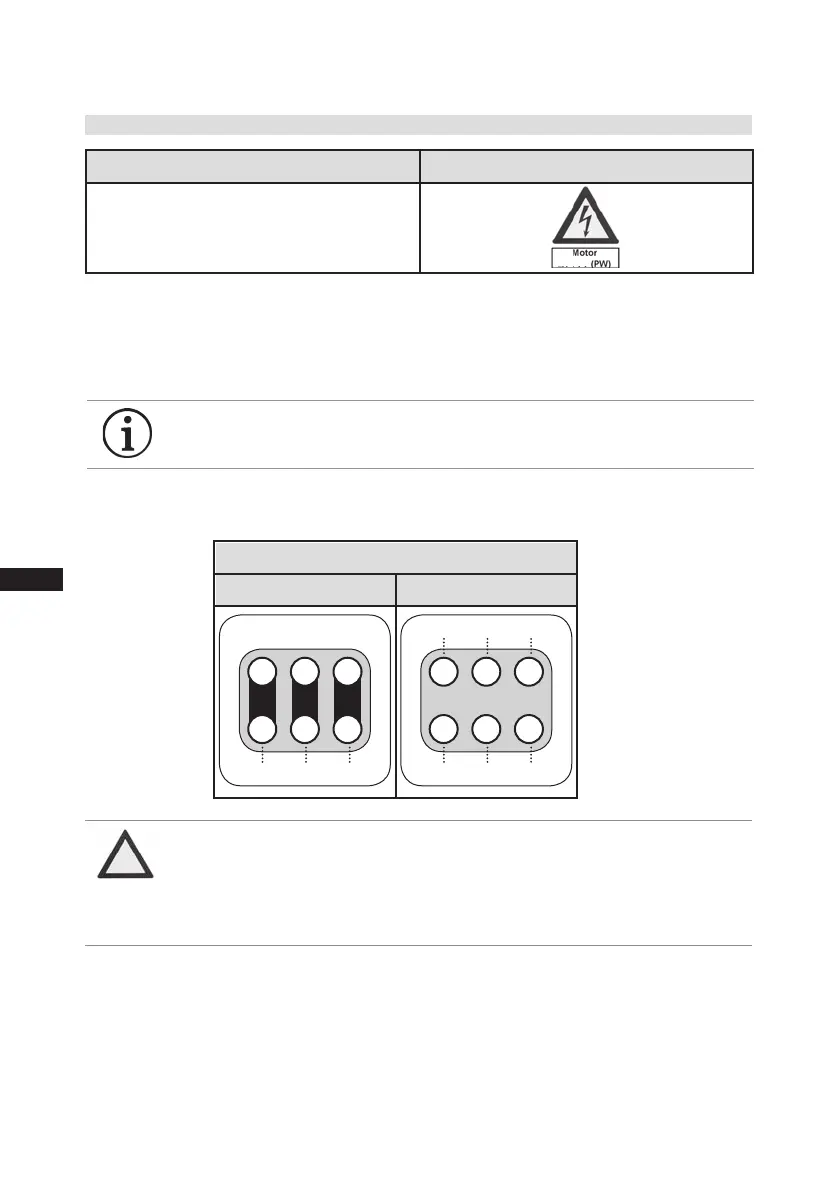

400 V

Direktstart YY Teilwicklungsstart Y/YY

1V1 1W11U1

2W12V12U1

L3L2L1 L3L2L1

L3L2L1

1V1 1W11U1

2W12V12U1

Direct start

Part winding start

6| Electrical connection

6.3 Standard motor, design for direct or partial winding start

The

motoriswiredfordirectstart(YY)atthefactory.ForpartwindingstartY/YYthebridgesmustbe

removedandthemotorfeedlineconnectedaccordingtothecircuitdiagram:

INFO A mechanical unloaded start with bypass solenoid valve is

notrequired

.

ATTENTION Failure to do this results in opposed rotary elds and results in

damage to the motor. After the motor starts up via partial winding

1, partial winding 2 must be switched on after a maximum delay

of one second . Failure to comply can adversely affect the service

life of the motor.

Compressors with this marking are suitable for direct or partial winding start. The motor winding is

subdivided

intotwoparts:

Part winding 1 = 50% and part winding 2 = 50%.

This winding division reduces the start-up current needed for a part winding start to approx. 50% of

that for a direct start.

Designation on the name plate Sticker on the terminal box

Y/YY

Y/YY

Loading...

Loading...