36

D

GB

F

E

09726-06.2018-DGbF

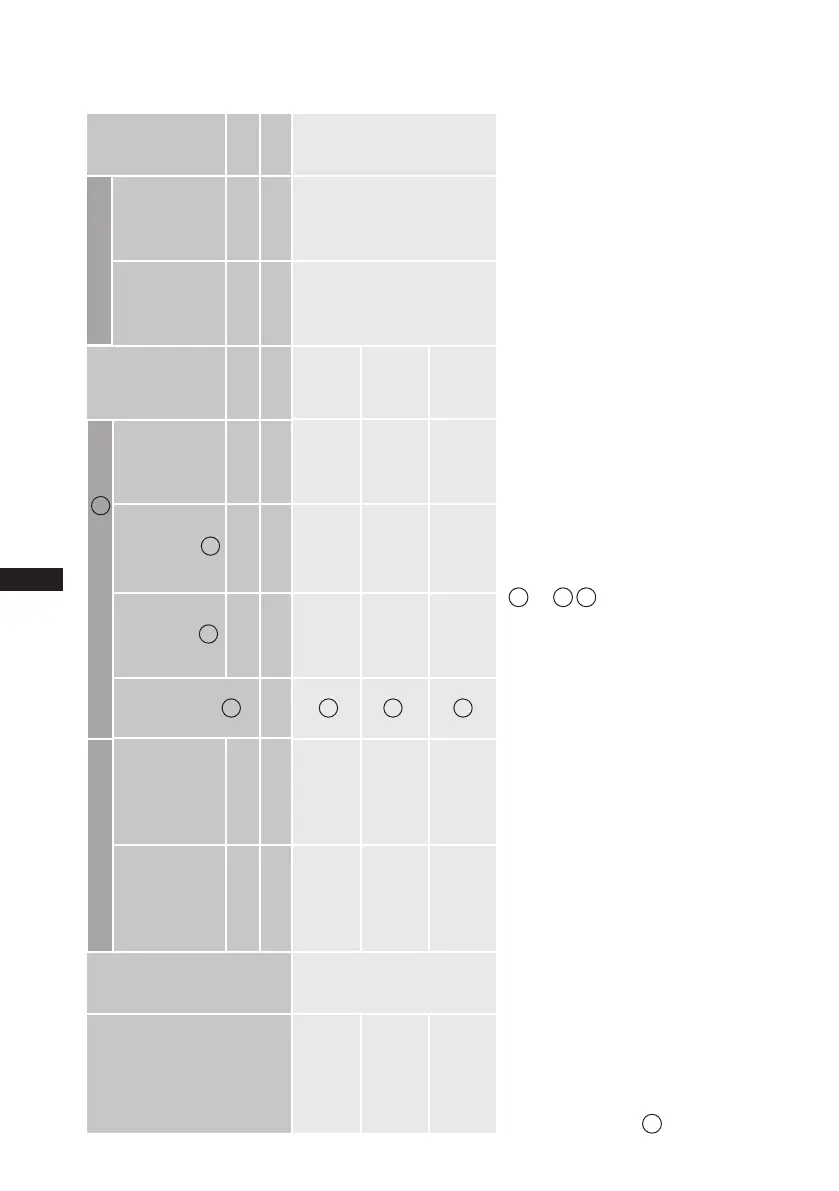

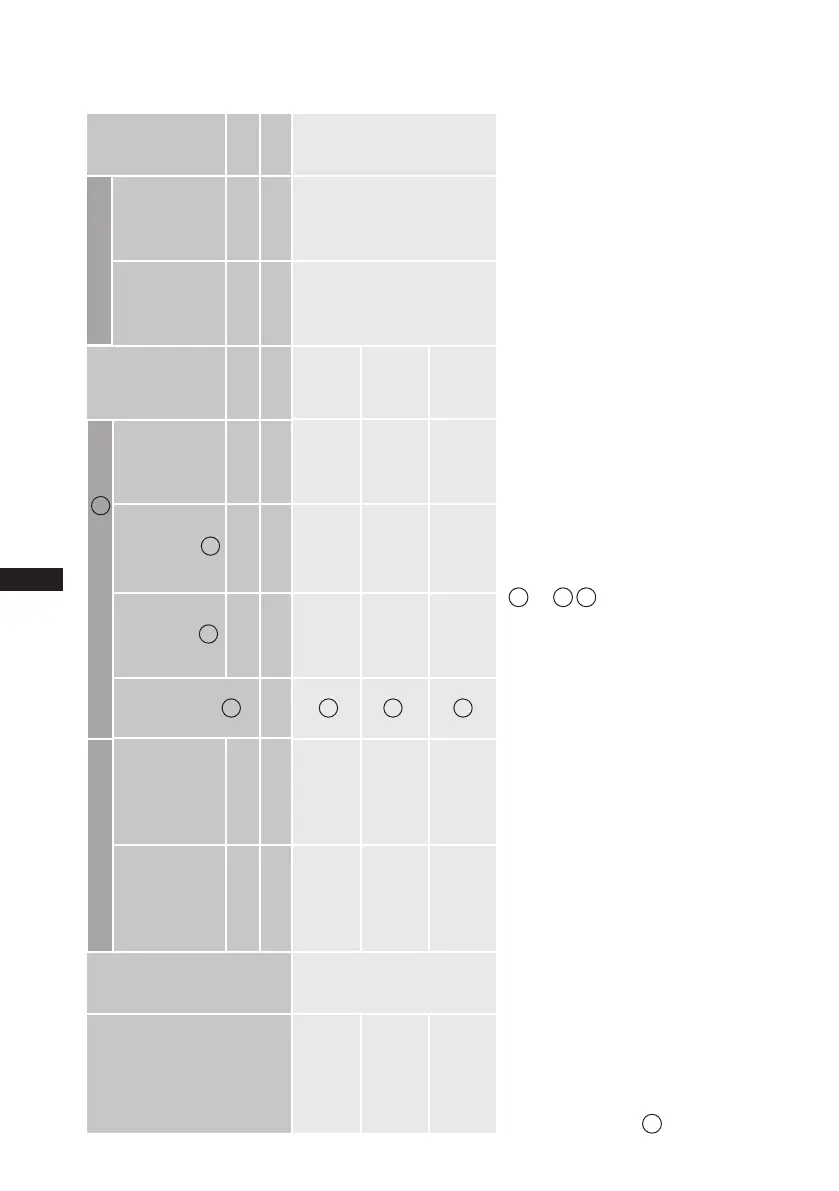

9| Technical data

1

2

3

4

*

PW = Part Winding, motors for part winding starting

1 = 1. part winding, 2 = 2. part winding

¹

)

For solder connections ²

)

in standard design

LP = Low pressure stage HP = High pressure stage

Oil sump heater:230V-1-50/60Hz140W

Tolerance(±10%)relativetothemeanvalueofthevoltagerange.

Takeaccountofthemax.operatingcurrent/max.powerconsumption

for design of fuses, supply lines and safety devices.

Allspecicationsarebasedontheaverageofthevoltagerange

380-420VY/YY-3-50HzPW,440-480VY/YY-3-60HzPW

> Winding ratios:50%/50%

HGZ7/1620-4

6

93,7/46,9 112,5/56,2 50 27,0 175/269 294

35(1

3

/

8

) 54(2

1

/

8

) 4,5HGZ7/1860-4 107,6/53,8 129,1/64,6 55 30,0 175/269 290

HGZ7/2110-4 122,4/61,2 146,9/73,5

65

36,0 232/357 288

Type

No. of cylinders

50 Hz

(1450

rpm)

LP HP

60 Hz

(1740 rpm)

LP HP

Voltage

Max.

operating

current

Max.

power

consump

-

tion

Starting

current

(rotor

locked)

Weight ²

)

Discharge

line

DV

Suction

line

SV

Oil charge

m

3

/h m

3

/h A kW A kg mm(inch) mm(inch) Ltr.

*PW 1+2 *PW1/PW 1+2

Connections ¹

)

Electrical data

Displacement

3

1

4

4

4

2

2

Loading...

Loading...