D

GB

F

E

11

96182-09.2013-DGbFEI

4| Compressor assembly

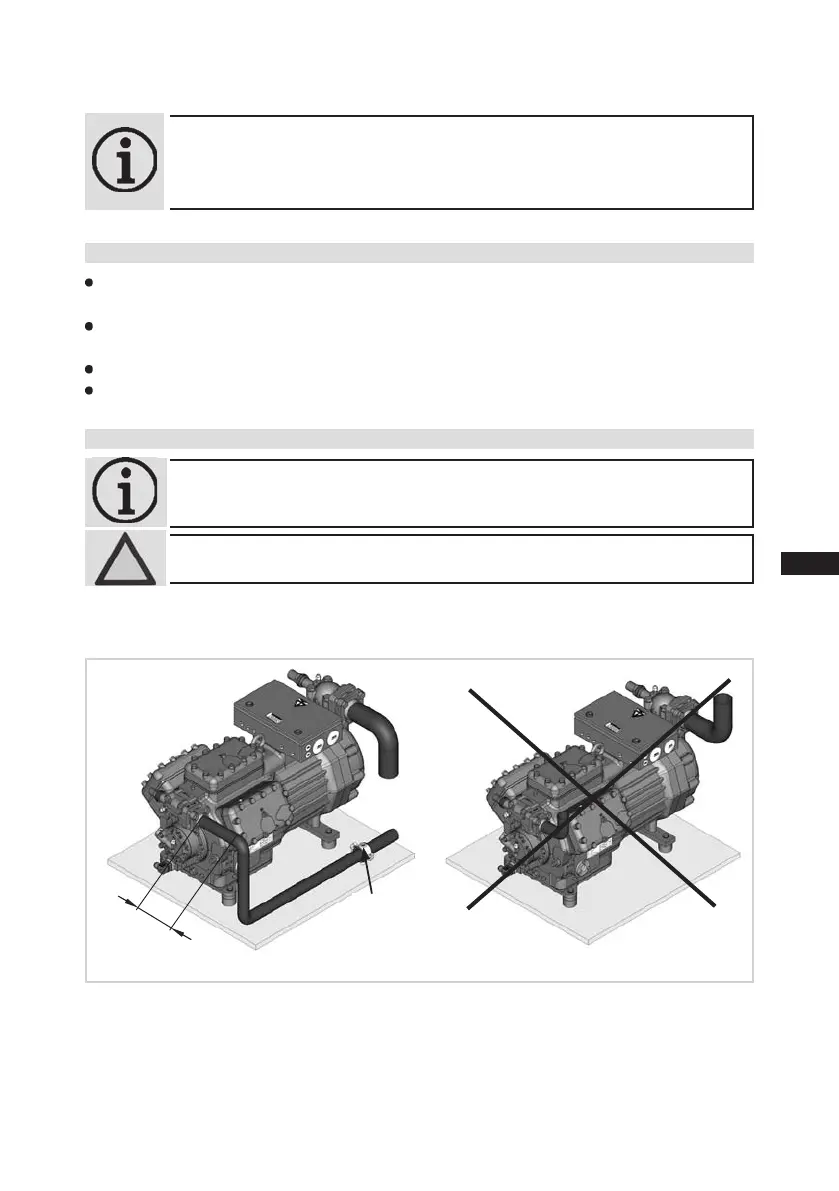

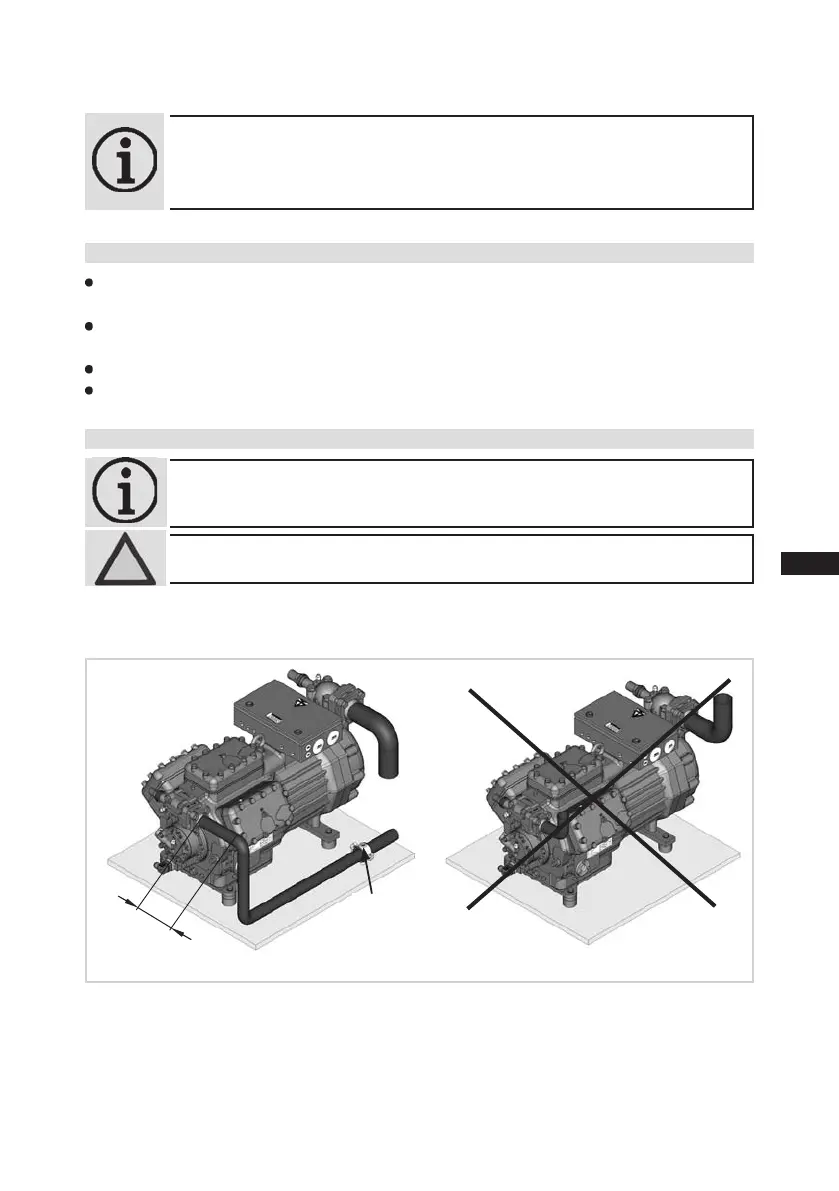

Rigid

fixed point

Fig.10

INFO! ForcompressorsHGX7/2110-4andHGX7/2110-4S,solderconnections

are mounted to the suction shut-off valve for pipe diameter 64.

Solder connections for pipe diameter 2 5/8“ are enclosed with the

compressor.

As short as

possible

4.4 Laying suction and pressure lines

INFO! Proper layout of the suction and pressure lines directly after the

compressor is integral to the smooth running and vibration behaviour

of the system.

ATTENTION! Improperlyinstalledpipes can cause cracks and tearswhichcan

result in a loss of refrigerant.

A rule of thumb:

Alwayslaytherstpipesectionstartingfromtheshut-offvalvedownwards and

parallel to the drive shaft.

4.3 Pipes

Pipesandsystemcomponentsmustbecleananddryinsideandfreeofscale,swarfandlayersof

rustandphosphate.Onlyuseair-tightparts.

Lay pipescorrectly. Suitable vibration compensatorsmust be provided to prevent pipes being

crackedandbrokenbyseverevibrations.

Ensureaproperoilreturn.

Keeppressurelossestoanabsoluteminimum.

Loading...

Loading...