Sicherheitsventile / Safety Relief Valves

GEA Germany

GEA AWP GmbH

Armaturenstr. 2

17291 Prenzlau, Germany

Tel +49 3984 8559-0

Fax +49 3984 8559-18

info@awpvalves.com

awpvalves.com

The information contained in this brochure merely serves as a

non-binding description of our products and is without guarantee. Binding information, in particular relating to capacity data an

d suitability for specific applications, can only be provided wit

hin the framework of concrete

inquiries. Printed on chlorine

-free bleached paper · Printed in Germany · Subject to modification

5 ∙ Betriebsvorschriften / Operating Instructions

verlegt sein, dass die statischen dynamischen

Reaktionskräfte sowie die thermischen

Beanspruchungen sicher aufgenommen werden

können. An Sicherheitseinrichtungen, bei denen durch

das Austreten eines zündfähigen Mediums direkt oder

indirekt Gefahren für die Personen oder die in der

Umgebung befindlichen Zündquellen entstehen,

müssen geeignete Schutzmaßnahmen getroffen

werden (z.B. Abblasen in eine sichere Umgebung).

Die empfohlenen Explosionsbegrenzungsmaßnahmen

bzw. die Empfehlungen für das Tragen der

persönlichen Schutzausrüstung im Sinne der Produkt-

Sicherheitsdatenblätter sind zwingend beim Lösen von

Verschraubungen oder Entspannen der Druckfeder zu

beachten und einzuhalten.

Instandsetzungsmaßnahmen an den

Sicherheitseinrichtungen dürfen ausschließlich nur

durch den Gerätehersteller durchgeführt werden.

Ein Wechsel der Sicherheitseinrichtung darf nur im

gesicherten drucklosen Zustand der Anlage und deren

Leitungen durchgeführt werden. Bei brennbaren

Gasen wie z.B. Propan, Butan, Methan, etc., ist

funkenarmes Werkzeug hierzu zu verwenden.

Bei der Verwendung von Ammoniak als Kältemittel

sind besondere Sicherheitsmaßnahmen zu beachten

(siehe auch Sicherheitsdatenblatt).

Nach der Installation der Sicherheitsarmatur ist ein

Dichtheitstest durch eine befähigte Person

durchzuführen. Die Überprüfung des Ansprechdruckes

ist in regelmäßigen Abständen anhand der

Einstellbescheinigung vorzunehmen.

4. Anwendung

AWP Sicherheitsventile sind geeignet für den Einsatz

in Kältemittelkreisläufen für Industrie-Kälteanlagen als

Abblase- bzw. Überströmventil (! nur SVU 457 / 458).

Sicherheitsventile sind Sicherheitseinrichtungen zum

Schutz der Kälteanlage oder ihrer Bauteile vor

unzulässiger Druckbeanspruchung (siehe auch EN

378 Teil 2). Sie entsprechen dem AD2000 -

Regelwerk.

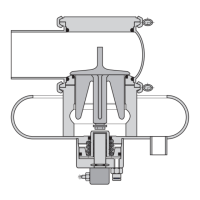

5. Funktionsbeschreibung

AWP Sicherheitsventile öffnen nach dem Ansprechen

innerhalb von 10 % Drucksteigerung bis zum

konstruktiv begrenzten Hub. Sie schließen innerhalb

einer Druckabsenkung von 10 % unter dem Ansprech-

punkt. Die Typen SVU 457 / 458 sind mit einem Ge-

gendruck-kompensierenden Metallbalg ausgestattet,

d. h. das Ventil arbeitet unabhängig vom Gegendruck!

! Ansprechdruck = Einstelldruck !

Zur Gewährleistung des K

dr

-Wertes darf der

Gegendruck [abs.] max. 25 % des Einstelldruckes

[abs.] betragen.

Die Typen SVA 455 / 456 arbeiten abhängig vom

Gegendruck!

! Ansprechdruck = Einstelldruck + Fremdgegendruck!

Zur Gewährleistung des K

dr

-Wertes darf der Gegen-

druck [abs.] max. 10 % des Ansprechdruckes [abs.]

betragen.

operating conditions have to be considered. Safety

devices that are subject to discharging incendive

media and therefore constitute a direct or indirect

hazard to persons and ignition sources in their

environment must be appropriately protected (e. g.

discharging into a safe environment).

The recommended steps to limit potential explosions,

resp. the recommendations for wearing personal

protection equipment have to be attended and

followed mandatorily when screw connections are

being loosened or the pressure spring is being

slackened.

Safety devices may be exclusively maintained by the

manufacturer.

Safety devices may only be replaced when the plant

and its pipes are secured and depressurized. When

inflammable gases such as propane, butane, methane

are being used this has to be done with tools that do

not create sparks.

When ammonia is being used as refrigerant, special

safety instructions have to be followed (see safety data

sheet).

After the safety valve has been installed a leakage test

has to be performed by an authorized person.

The response pressure has to be checked in regular

intervals according to the setting certificate.

4. Application

AWP safety valves are suitable for being employed as

relief or overflow valves in the refrigerant cycles of

industrial refrigerating plants (! only SVU 457 / 458).

Safety valves are safety devices for protecting the

refrigerating plant or its components from excess

pressure (see also EN 378 part 2). They correspond to

the AD2000 set of rules.

5. Functional Description

Once an AWP safety valve has responded, it opens

within a pressure increasing range of 10 % until it

reaches the constructional limit. They close within a

pressure dropping range of 10 % below the set

response pressure.

The types SVU 457 / 458 are equipped with a metal

bellows to compensate the back pressure, i.e. the

valve is independent of back pressure!

! Response pressure = set pressure!

The back pressure [abs.] may not exceed 25 % of the

set pressure [abs.] in order to ensure the K

dr

-value.

The types SVA 455 / 456 work dependent on back

pressure.

! Response pressure = set pressure + foreign back

pressure!

The back pressure [abs.] may not exceed 10 % of the

set pressure [abs.] in order to ensure the K

dr

-value.

Sicherheitshinweise, Anwendung, Funktionsbeschreibung

Safety Advices, Application, Functional Description

Loading...

Loading...