www.gemu-group.com 13 / 34 GEMÜ 3040

9.2 Installation position

NOTICE

▶ There is an arrow on the measurement channel of the

product symbolizing the direction of flow measurement.

The measurement device must be installed so that the

medium flows through it in the direction of the arrow.

TOP -> outlet

BOTTOM -> inlet

Fig.4: Ideal installation position of the product

To ensure gas is detected as quickly as possible, it is import-

ant to keep the line path between the storage tank and the

product as short as possible. Faultless measurement can only

be ensured if the line is filled completely and the liquid does

not outgas.

Deviating from this, it can be advantageous for dosing applic-

ations to position the product as closely as possible to the

dosing valve as the cross-sections of hose lines increase de-

pending on the system pressure. This can lead to differences

in reproducibility.

NOTICE

▶ It must be ensured that no gas elements dissolve out of

the medium. Depending on the liquid, sufficient back

pressure on the outlet of the product can prevent the li-

quid from outgassing. Suitable sealing material must be

used during assembly. The use of Teflon tape or similar

must be avoided.

Any carried solid matter can lead to measurement errors.

When using pumps, the product must be installed in the flow

direction behind the pump on the pressure side to ensure that

there is sufficient pressure. The maximum pressure rating of

the product must be taken into account.

Straight and uninterrupted inlet and outlet distances for the

product must be complied with for a correct volume flow

measurement. Dependent on the nominal size, these are at

least:

DN10 DN15 DN20 DN25 DN32 DN40 DN50

Inlet distance 10

cm

30

cm

40

cm

40

cm

40

cm

45

cm

60

cm

Outlet distance 0 cm 5 cm 10

cm

20

cm

20

cm

20

cm

20

cm

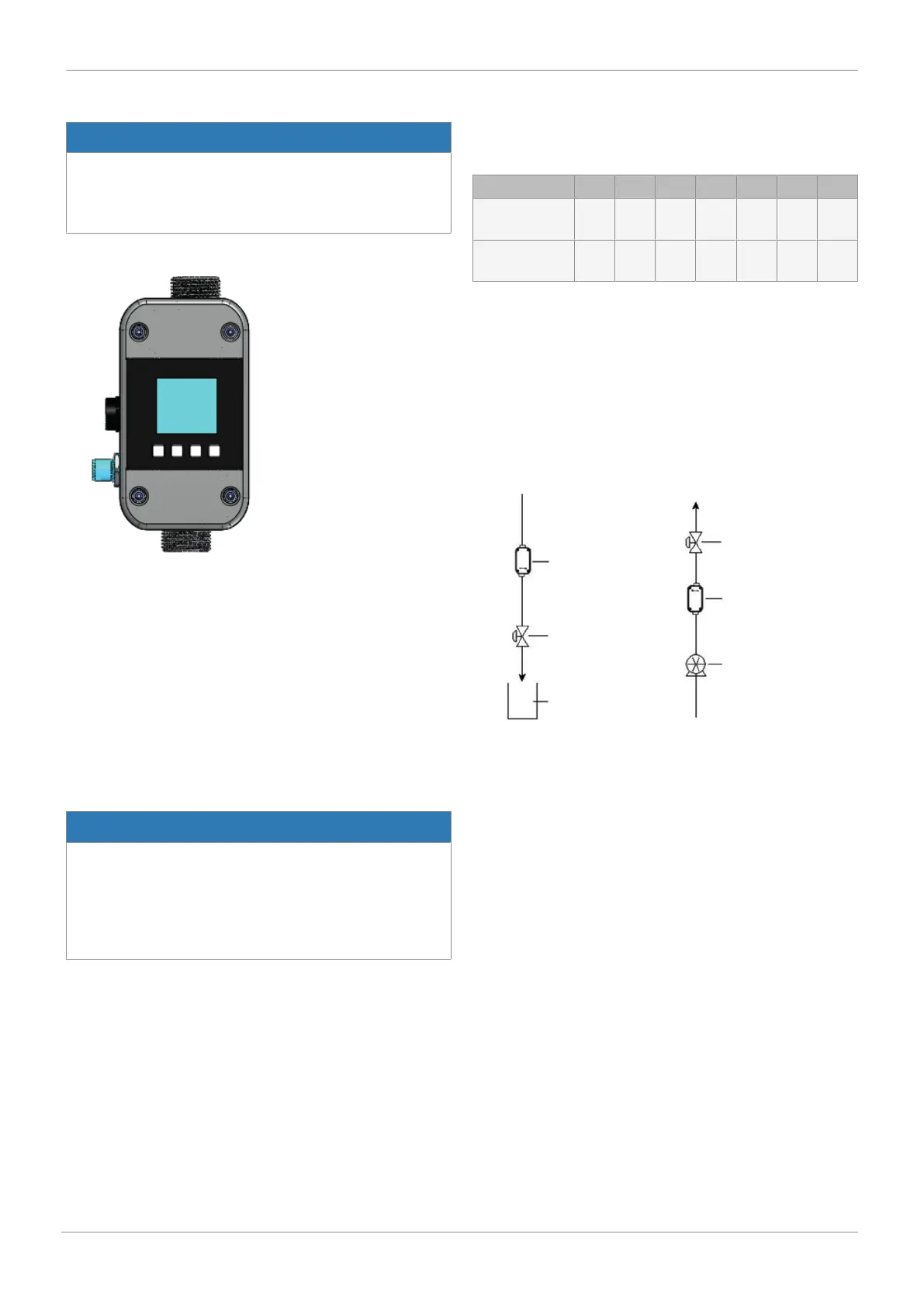

9.3 Installation of the measurement device

The measurement device is installed using the process con-

nections in the pipe or tube line. To ensure optimal degassing,

we recommend mounting the product vertically in the line.

The device must not be mounted behind an outlet valve as it

can run empty otherwise. To prevent gas diffusion and blister

formation of the medium during flow measurement, the

product must always be installed on the pressure side of the

system pump.

GEMÜ 3040

Valve

Container

Process valve

Pump

GEMÜ 3040

Fig.5: Installation situation

9 Installation in piping

Loading...

Loading...