A

TYPICAL OPEN

BEAM CEILING

LAG

SCREWS

B

BOLTS/

NUTS

Attach hangers

(not

supplied)

LAG

SCREWS

(not

supplied)

Bolt 3/8" 16 x 7/8"

3/8"-16

Lock Nut

x 2

x 2

Use cross piece

(not supplied) for

attaching to

hidden joists.

POWERHEAD

DOOR

WALLWALL

MEASURE HERE

MEASURE HERE

FINISHED CEILINGS

WITH HIDDEN JOISTS

directly to joists.

Support opener or have an

assistant hold it during this step

ACCESSORY

HOLES

Plug accessory

holes now.

NETWORK BBU

3-7/8" Clevis Pin, Long & Push Nut

x 1

WARNING

CAUTION

Header Bracket must be fastened to

garage framing. DO NOT fasten to

drywall, particle board, plaster, or

other such materials.

Door springs are under high tension. If spring or shaft is in the

way, measure above spring or shaft on the garage door

centerline and mark as location for header bracket. DO NOT

ATTEMPT TO MOVE, ADJUST, OR REMOVE DOOR SPRING!

CLEVIS PIN

and PUSH NUT

DOOR

CENTERLINE

HEADER

HIGHEST

POINT

of travel

PLUS**

TORSION SPRING

CEILING

WALL

TOP OF DOOR

HEADER

BRACKET

MAX. 6" FROM WALL

IN LOW OVERHEAD SITUATIONS,

HEADER BRACKET CAN BE MOUNTED

ON CEILING AS SHOWN

STEP 3 – Attaching Rail to Header

(part1)

USE ORANGE PARTS BAG

.gnivom si rood elihw gninepo fo raelc elpoep peeK •

• Do Not allow children to play with the door operator.

• Do Not .gnirps nekorb a sah taht eno ro smaj taht rood a etarepo

• Turn off power before removing operator cover.

raen ro dehcnip ton era seriw erus ekam ,revoc gnicalper nehW •

moving parts.

• Operator must be properly grounded.

• Do Not try to remove, repair or adjust springs or anything to

leets ,skcolb doow ,sa hcus ,denetsaf era strap gnirps rood hcihw

brackets, cables or other like items.

• Repairs and adjustments must be made by a trai

ned door system

.snoitcurtsni dna sloot reporp gnisu naicinhcet

DANGER

:

CAUTION

:

Overhead doors are large, heavy objects that move with the help of springs

under high tension and electric motors. Since moving objects, springs

under tension, and electric motors can cause injuries, your safety and the

fI .launam siht ni noitamrofni eht gnidaer uoy no dneped srehto fo ytefas

you have questions or do not understand the information presented, call

The Genie Company or your local Genie Factory Authorized Dealer.

In this section, and those that follow, the words Danger, Warning and

Caution are used to emphasize important safety information.

The word:

indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

indicates a potentially hazardous situation

which, if not avoided, may result in injury or property damage.

The word NOTE is used to indicate important steps to be

followed or important considerations.

WARNING

:

WARNING–A MOVING DOOR

Could result in serious injury or death.

WARNING–AN ELECTRICAL SHOCK

Could result in serious injury or death.

WARNING–HIGH SPRING TENSION

Could result in serious injury or death.

TOOLS RECOMMENDED

P/N 37067501312

01-11

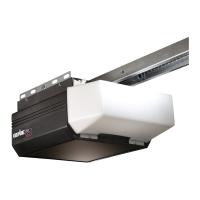

ASSEMBLY/INSTALLATIONINSTRUCTIONS

FOR

SCREW DRIVE MODEL GARAGE DOOR OPENERS

05-11

BLUE PARTS BAG ORANGE PARTS BAG

GREEN PARTS BAG

COTTER PIN (X 1)

TAPERED

FLANGE SCREW

1/4-14 x 3/4 (X 4)

(X 4)

LAG SCREW

5/16 X 1-3/4 (X 2)

LAG SCREW

5/16 X 1-3/4

(X 2)

HEADER

BRACKET (X 1)

WIRE CLIP (X 4)

CLEVIS PIN, LONG (X 1)

RELEASE

HANDLE

SELF-TAPPING SCREW,

1/4 X 3/4 (X 2)

INSULATED

STAPLE

1/4 X 3/4 (

˜

30)

BOLT,

5/16-18 X 3/4

(X 2)

LOCK NUT (SERRATED),

5/16-18 (X 2)

˜

(NOT INCLUDED

IN PRO UNITS)

L

3/8-16 (X 2)

CLEVIS PIN

3/8-15/16

(X 1)

DOOR

BRACKET

(X1)

SELF-DRILLING

SCREW,

1/4-20 X 3/4 (X 3)

LAG

COTTER PIN (X 1)

A E E

FLANGE SCREW

L

X 1)

1)(X )

STEP 1– Rail Assembly

STEP 2 – Attaching Rail to Powerhead

USE BLUE PARTS BAG

NOTE

STEP 3 – Attaching Rail to Header (part 2)

USE ORANGE PARTS BAG

PLUGS IN SMALL CLEAR BAG

Figure 1

1. If marked header bracket position

is above header, attach 2" x 6" board

across wall studs to create

mounting location.

2. Place bracket on your line and mark

hole locations. Drill 5/32" pilot holes.

3. Fasten bracket with lag

screws provided.

Figure 2

4. Carefully lean rail/opener assembly against garage door wall with

pulley assembly next to header bracket. Place cardboard, rag or any

soft material under powerhead to protect it. It may be necessary to

elevate the powerhead in order for the rail to clear the torsion spring.

5. Align pulley assembly and rail with side holes in

bracket and fasten with clevis pin and push nut.

STEP 4 – Mounting Powerhead

Continue supporting the opener.

(This step is easier with two people.)

1. Align opener with center of door. Measure from each side of door to where rail meets

powerhead. Measurements must be equal. Figure 1. Mark location.

2. Attach Mounting Straps in position.

3. While supporting opener, carefully open door. Raise opener to desired height, being

sure to allow clearance between rail and door as door passes through its highest point:

– This should be at least 2" on a one-piece door.

– Rail should be near level with fl oor on a sectional door.

4. Fasten opener to mounting straps using nuts and bolts indicated. Figure 2.

STEP 5 – Attaching Door Bracket

SECTIONAL DOOR (Lightweight)

Doors come both with & without braces where door bracket

attaches. Illustration a. and b. (without) and c. (with).

1. Regardless: the door bracket location is the same. On door centerline and higher than the top

set of door rollers.

• With a brace you may need to drill mounting holes through it. You may also be able to attach door

arm directly to the brace and eliminate the need for the door bracket.

2. Using door bracket as a template–mark the hole locations.

3. Drill 1/8" pilot holes and fasten with 1/4"-20 x 3/4" self-drilling screws provided.

SECTIONAL DOOR (Wooden)

1. Follow Lightweight instructions 1 and 2.

2. Drill 5/16" holes completely through door and fasten with 5/16" x 2" carriage bolts and nuts

(not furnished).

ONE-PIECE DOOR

1. Hold door bracket on door centerline, high as possible, on door face or top edge (preferred) and

mark hole locations.

2. For top edge (illustration d.):

• Drill 5/16" holes through door frame. Fasten with 5/16" x 2" bolts and nuts.

Face mount (illustration e.):

• Drill 5/16" holes through top door frame and fasten with 5/16" x 4-1/2" carriage bolts and nuts.

OR Fasten using 1-1/2" to 2" lag bolts. You must drill pilot holes to avoid splitting the frame.

USE ORANGE PARTS BAG

STEP 5b – Attaching Door Arms

USE BLUE & GREEN PARTS BAG

Figure 1

Figure 2

5/16"-18 x 1"

Bolt

5/16"-18

Lock Nut

x 2

x 2

x 1

x 2

Clevis Pin

3/8" x 15/16"

Cotter Pin

.073" DIA.

BLUE

BAG

GREEN

BA

G

BLUE

BAG

GREEN

BAG

USE BLUE PARTS BAG

DOOR

CENTERLINE

VERTICAL BRACE

OR

DOOR CENTERLINE

Doors made of masonite, lightweight wood, fiberglass, and sheet metal must be properly braced before mounting door

opener. Contact door manufacturer or distributor for any questions or concerns. The Genie® Company is not responsible for

any damage caused due to an improperly braced door.

CAUTION

a.

d.

b.

c.

e.

Rollers

ATTACH

NO LOWER

THAN TOP

ROLLERS

©2011 GMI HOLDINGS, DBA The Genie® Company

1/4-14 x 3/4"

Tapered Flange Screw

x 4

* Some units are equipped with amotion sensor.

Take special care to prevent damage.

This sensor works by detecting

body heat. Range of detection

may be reduced when temperature

in the garage is close to body

temperature. (DO NOT remove

foam cushion from underside

of opener.)

This opener includes parts and supplies needed for installation in MOST garages and on MOST garage doors. There are many variations of garages and

garage doors. A few additional parts and supplies may be needed for installation in YOUR garage and to YOUR garage door. While going over the checklist below,

used–does it extend far enough above the spring(s) to allow mounting of the Header Bracket. If not, or if you can’t tell–you will probably need a piece of 2" x 6"

need fasteners for mounting to the track itself or some other material? 4) Measure the height of your door. If it is taller than 7', you will need a Rail Extension Kit.

Is there an electrical outlet within approximately 3' of the point where the powerhead will be? If not you need to contact a licensed electrician.

Check condition of the door and all its associated hardware: Tracks, springs, hinges, rollers. Is anything loose or appear worn? If so, call a trained profes-

sional for an evaluation and repairs if needed. DO NOT ATTEMPT TO ADJUST SPRINGS OR THEIR ATTACHED PARTS!

Operate the door manually. Does it move freely and smoothly? Check the balance of the door by lifting it by hand approximately halfway open and let go. It

should stay put or move very slowly. If not, call a trained professional for repairs.

Remove all ropes and remove or disable all locks connected to the garage door. It is also recommended tha T-handles be removed. Closed loop lifting

handles with no protruding parts can remain.

1 READ AND FOLLOW ALL SAFETY, INSTALL ATION AND OPERATION INSTRUCTIONS. If you have any questions or do not understand an instruction, call The Genie®

Company or your local Genie® Factory Authorized Dealer.

2 Do Not install operator on an improperly balanced door. An improperly balanced door could cause severe injury. Repairs and adjustments to cables, spring

assembly, and other hardware must be made by a trained service person using proper tools and instructions.

3 Remove all ropes, and disable all locks connected to the door before installing operator.

4 Install door operator 7 feet or more above the floor. Mount the emergency release knob 6 feet above the floor.

5 Do Not connect the operator to the source of power until instructed to do so.

6 Locate the control button: A) Within sight of door. B) At a minimum height of 5 feet, so small children cannot reach it. C) Away from all moving parts of the door.

7 Install the entrapment WARNING label next to the wall button or console. Install the emergency release tag on, or next to, the emergency release Handle.

8 The operator must reverse when the door contacts

a 1-1/2 inch high object on the floor at the center of the doorway. This is about the size of a 2” x 4” board laid flat.

!

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH:

WARNING

:

STEP 1

STEP 2

STEP 3

STEP 4

STEP 6

STEP 5

PUSH NUT

(X 1)

(X 2)

3

BOLT

COUPLER

8-16 X 7// 8

(X 2)

SAFE-T-BEAM® SOURCE (X 1)

SAFE-T-BEAM® SENSOR (X 1)

LAG SCREW,

1/4 X 1-1/4 (X 4)

SMALL CLEAR BAG

RUBBER

PLUGS, (X 2)

SMALL CLEAR BAG

CLIP, (X 2)

COLLAR, (X 2)

YELLOW PRT BAG

SAFE-T-BEAM® SOURCE

F

C

B

B

A

A

RAIL CONNECTOR

RAIL CONNECTOR

CARRIAGE

F

F

Mounting Straps

(set aside, not used

until INSTALL STEP 3)

G

Slide shuttle into door end of rail (NOTE DIRECTION). Rail fits into grooves

along sides of shuttle. When shuttle moves over the carriage, it will lock

into place.

F

F

F

B

C

A

B

DETAIL 1

DETAIL 2

A

D

E F

B

C

G

Opener End Rail Section, Middle Rail Section, Door End Rail Section

Screw Clips, Screw Collars, and Rail Connectors Mounting Straps

1. Sections of rail assembly slide together in order shown.

2. Slide screw connection end of opener end section into

rail connector

until it locks into place.

4. Slide

6.

Slide

middle section into same rail connector until it locks.

Check closely to ensure you connect proper end of section. Short screw connection piece mates

with long connection piece.

5.

Connect the two screw sections. Screw sections can be rotated for alignment.

See DETAIL 2 below.

8. Connect the two screw sections. See DETAIL below.

second rail connector onto middle rail section until it locks.

7.

Complete rail assembly by sliding screw connection end of door end section

(has a blunt ended screw) into rail connector until it locks.

3. Attach Shuttle to Carriage in middle section. See DETAIL 1 below.

INSTALLING

CLIPS & COLLARS

Slide Collar over long Hook

Slide Collar over Joint

Snap Clip behind Collar

1

3

4

Mate Hooks

2

ENGAGED

DISENGAGED

TOWARD

GROOVES

ALONG

SHUTTLE

DIRECTION

D

E

DOOR

The COUPLER, used to connect the drive screw to the

motor shaft, has a small hole on one end and a larger

hole on the opposite end.

• The smaller hole fits over the motor shaft.

• The larger hole fits over the drive screw.

3.

Place rail mounting bracket on top of rail

with tongue of bracket inserted into slot in rail.

MAKE SURE RAIL IS CLOSED SIDE UP-

SCREW UNDERNEATH.

4. Align holes in bracket with those on

power head* and fasten with tappered

flange bolts supplied.

COUPLER

TONGUE

TONGUE

Top of

Rail

SLOT IN RAIL

* Use soft material to cushion

under side of opener in order

to protect powerhead.

MOTOR

SHAFT

DRIVE

SCREW

SMALL HOLE

LARGE HOLE

1. Place shaft coupler large hole over end

2.

Align drive screw/coupler (small hole) with motor

shaft and slide together.

of drive screw.

Figure 1

MOTION

SENSOR

PROTECTIVE CUSHION

x 3

1/4"-20 x 3/4"

S

elf Drilling Screw

LINE UP AND CONNECT DOOR ARMS AS SHOWN.

MAKE SURE CARRIAGE IS DISENGAGED, SO IT WILL

MOVE AS NEEDED TO ALIGN HOLES.

SECTIONAL DOOR

1.

Straight arm attaches to carriage using

clevis pin and cotter pin provided

2. Curved arm attaches to door bracket using

clevis pin and cotter pin provided.

ONE-PIECE DOOR

1.

Straight arm only is used and connects to

carriage and door bracket both with clevis

pins and cotter pins provided.

SECTIONAL DOOR

HEADER

BOLT/

NUT

ADDED MOUNTING MATERIAL

A

WALL

A=

MAKE THIS THE

SHORTEST OVERALL

COMBINED LENGTH

OF THE DOOR ARMS

ONE-PIECE DOOR

DOOR

DOOR

WALL

HEADER

DISENGAGED

EMERGENCY RELEASE LEVER

CLEVIS PIN

COTTER PIN

DISENGAGED

EMERGENCY RELEASE LEVER

FACE

SPRING

SPRING

30° max.

BASIC

OVERHAND

KNOTS

Do this with door fully closed.

1.

Tie knot in one end of red emergency release cord.

2.

Pass opposite end of cord up through red emergency

release handle and through hole in carriage release lever.

3.

Adjust height of handle to at least 6' above floor, and

1.

4.

Using the Emergency Release Cord, place the carriage

in the disengaged position (See STEP 1, DETAIL 1).

tie off cord. Cut off extra cord.

RED EMERGENCY

RELEASE HANDLE

IWC

ENTRAPMENT

WARNING LABEL

WARNING

:

Use of any other wall control can cause unexpected operation of the door and loss of the lighting feature. Locate wall console

within sight of the door and far enough from door to prevent contacting it while operating the console. Must be at least 5 feet

above floor to prevent small children from operating it.

STB

1

2

3

4

5 6

BWC

OR

TO POWERHEAD

Wall console #1 Wall console #2

Wall console #1 Wall console #2

TO WALL CONSOLE #1

W

B/W

W

B/

W

W

B/W

W

B/W

BOTH TO POWERHEAD

STB BWC IWC

NOT

USED

NOT

USED

NOT

USED

NOT

USED

FROM STBs

FROM WALL

CONSOLE

Wire connector

on Powerhead

Wire connector on

Powerhead

WALL

CONSOLE

TERMINAL

CONNECTIONS

A

B

STEP 6 – Safe-T-Beam®

1. Safe-T-Beam® does not have to be mounted

on garage door frame. Can be mounted

anywhere along garage door wall. Must

have clear line of sight between them

and top of lens must be between

5"- 6" above fl oor.

2. Hold mounting brackets against

desired surface , mark holes fasten with

lag screws or appropriate fasteners for

the material.

3. Route two (2) lengths of two (2) conductor wire

from powerhead, along top of rail, across header,

one to right, one to left and down to Safe-T-Beam®.

4. Fasten wire to rail with wire clips spaced evenly

along rail.

5. Fasten to header and wall with insulated staples

and cut off excess wire.

OPTIONAL DUAL WALL CONSOLE INSTALLATION

STEP 7 – Installing Wall Console

USE ORANGE PARTS BAG

Use only a Series III wall console when adding a second. The optional second Genie® Series III wall

console must be purchased separately.

1. Route wire from powerhead to desired location for

wall console. Some homes are pre-wired and they may not be color-coded. The wall console circuit

is not polarized, therefore, either wire may be connected to either terminal without a problem.

2. Secure wire with insulating staples and cut off excess wire.

3. Attach wires to wall console as shown. Insert opposite end of wire through Control Wire Tube on

powerhead illustrated above and attach as shown.

4. Mount wall console with #6 screws provided.

5.

next to wall console.

STEP 10 – Connect to Power

with power cord

FOR GROUNDED OUTLET CONNECTION

1. Plug in the power cord. Coil excess cord and tape or twist tie it to top of powerhead (DO NOT

PLACE ABOVE LIGHT BULBS).

STEP 8 – Professional Connect to Power

FOR PERMANENT WIRING BY ELECTRICIAN

IF USING THE STANDARD POWER CORD,

SKIP TO STEP 9.

1. Cut existing wires OUTSIDE CHASSIS

.

2. The wire connections must be made INSIDE

CHASSIS, and there must be at least 6" of new

power supply line wire INSIDE CHASSIS. (Conduit

illustrated is optional.) (Conduit, strain relief and

wire nuts are not provided.)

WARNING:

DO NOT alter plug in any way! If you have no grounded

electrical outlets.

outlets, have one installed by a licensed electrician.

Opener must be properly grounded to prevent personal

injury and equipment damage. NEVER USE AN EXTENSION

CORD! Check local building codes for any requirement

that you must have a permanent hard-wired connection.

If required, it must be installed by a licensed electrician.

NEVER REMOVE MOTOR COVER. All work inside cover

must be performed by a licensed electrician using

proper tools and instruction.

STEP 9 – Finishing

)

WIRING CONNECTIONS

6. At Safe-T-Beam® source and sensor, attach wires at terminal screws.

Either wire may be connected to either terminal (Circuit is non-polar).

7. At powerhead, twist striped wires together. Twist white wires

together. Attach to plug-in terminals 1 & 2 (again either terminal is

fi ne). Bundle any excess slack and tape to top of powerhead

NOT DIRECTLY ABOVE LIGHT(S).

CONNECTION AT STB

CIRCUIT IS

NON-POLAR.

YOU MAY

CONNECT

EITHER WIRE

TO EITHER

TERMINAL.

LOCATED INSIDE LIGHT LENS

x 4

1/4"x 1-1/4"

Lag Screw

Top of

Bracket

6" max.

5" min.

NO HEIGHT ADJUSTMENT

IS NEEDED FOR FLOOR

MOUNTED UNITS.

SOURCE (red LED)

SENSOR

Wall

Mount

Floor Mount

STB

1

2

3

4 5 6

BWC AWC

WARNING

:

Verify there is NO POWER to the opener prior to

beginning any wiring installations or changes.

INSULATED STAPLES

x 4

WIRE CLIPS

WIRE

When using insulated staples, make only snug

enough to hold wire in place. Staples too tight

can cause damage to wire and cause

Safe-T-Beam® System to malfunction.

CAUTION

:

Wire Clips

95

ft

Wire

Adhesive pad on bottom. Remove paper

from adhesive pad and stick clip to rail.

30

Insulated

Staples

ORANGE

BAG

GREEN

BAG

NO WIRE OR STAPLES

PROVIDED IN PRO UNITS

OPERATOR STB CONNECTION

TO MAKE CONNECTIONS

Press in on orange tab, insert wire

into hole and release tab.

Press here to open lens. Use caution opening.

2. Swing lens up into place. It may be necessary

to squeeze lens slightly to align tabs with slots

at top of motor cover.

1. Install light bulbs and insert hinges into slots in

motor cover.

1

2

MOTOR COVER

MOTOR COVER

DO NOT EXCEED MAX. WATTAGE

1. The opener is now ready to program

for operation.

3 Instructions for programming the opener

are in your “OPERATION AND

MAINTENANCE MANUAL.”

CAUTION:

2. DO NOT RUN OPENER

UNTIL Travel Limits have been set.

Each light bulb must be 100 W or less.*

* Model 2562 requires light bulbs

of no more than 60 Watts.

1

2

TAB

HINGE

LATCH

USE YELLOW PARTS BAG

SERRE-FILS

WIRE NUTS

WHITE - NEUTRAL

GREEN - GROUND

BLACK - HOT

GND WIRE

CONNECTOR

TOROID

TOROID

SERRE-FILS

WIRE NUTS

WHITE - NEUTRAL

GREEN - GROUND

BLACK - HOT

GND WIRE

CONNECTOR

EXISTING

WIRE

NO TOROID

TOROID

NOT

USED

NOT

USED

NOT

USED

NOT

USED

WALL CONSOLE

CONNECTIONS

AT POWERHEAD

Post Entrapment Warning Label

STB BWC IWC

NOT

USED

NOT

USED

FROM STBs

FROM WALL

CONSOLE #1

FROM WALL

CONSOLE #2

x 2

5/16" x 1-3/4" Lag Bolt

**Highest point of travel plus:

Sectional door = Highest point plus 2.5"

One-piece door = Highest point plus 6"

THE RAIL IS CONNECTED

WITH THE CLOSED SIDE

FACING UP. THE SCREW WILL

BE UNDERNEATH AND NOT

VISIBLE WHEN VIEWED

FROM ABOVE.

3. Ensure latch snaps into place.

Opener is equipped with grounded electrical plug for

Loading...

Loading...