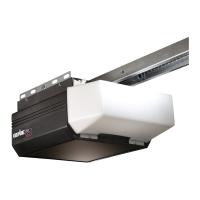

Do you have a question about the Genie SilentMax 1000 and is the answer not in the manual?

Describes hazards, symbols, and signal words like DANGER, WARNING, CAUTION.

Critical instructions to prevent injury or death during operation and maintenance.

Reversing systems that stop/reverse door on obstruction or contact.

Automatically sets force for safe opening/closing.

Watch Dog™ Monitoring and Manual Emergency Release functions.

Electronic programming and automatic lighting system features.

Optional feature for automatic light activation via motion.

Superior encryption for enhanced security.

Controls opener from inside, with indicator light and buttons.

Compatibility with vehicle's built-in remote systems.

Regulatory compliance for transmitters in US/Canada and internationally.

Explains programming buttons (PROGRAM, SET) and LED indicators.

Details how the Safe-T-Beam® system prevents closing on obstructions.

Introduces the four powerhead program menus: Remote, Limits, Force, and Speed.

Steps to set the down and up travel limits for the garage door.

Sets the force required for opening and closing the door.

Tests the safety reverse function by using a 2x4 board.

Step-by-step guide to program remotes to new Intellicode® 2 openers.

Guide to change Intellicode® 2 default to Intellicode® 1 mode.

Regulatory compliance information for FCC and IC.

Steps to program a wireless keypad to the opener.

Procedure to erase all programmed remotes from memory.

Explains indicator light, Open/Close, Light Control, and Sure-Lock™ buttons.

Lists essential monthly checks like reverse test, Safe-T-Beam, and door balance.

Procedures to check the proper functioning of the Safe-T-Beam system.

Steps to check if the door is properly balanced and moves smoothly.

Guidance on lubricating rollers, bearings, and hinges.

Instructions for replacing the powerhead light bulbs safely.

How to reset previously set travel limits.

Steps to disconnect and reconnect the carriage to the drive mechanism.

Guide to replacing the battery in the remote control.

How to adjust tension on the chain or belt drive.

Detailed steps and chart for adjusting door closing force levels.

Steps and chart for adjusting door opening and closing speed settings.

Wiring diagram for the power cord and circuit board connections.

Wiring diagram for motors and the Safe-T-Beam® system.

Wiring diagram for wall console and optional sensors.

Steps for diagnosing opener and door movement issues.

Solutions for remote control range or non-response problems.

Diagnosing issues with door reversing or stopping during travel.

Troubleshooting for doors only opening, stopping mid-open, or starting unexpectedly.

Addressing noise and slow performance issues.

Indicates normal operation when both LEDs are OFF.

Explains LED patterns for issues like limits, programming, or component failure.

LED patterns for Safe-T-Beam or door contact problems.

LED indication for thermal cutout activation.

Details warranty duration for Motor/Gearbox, Belt, Chain, Core Parts, and Accessories.

| Horsepower | 3/4 HPc |

|---|---|

| Max Door Weight | 500 lbs |

| Motor Power | DC |

| Max Door Height | 8 feet with extension kit |

| Security | Intellicode rolling code technology |

| Drive Type | Belt Drive |

| Lighting | 2 bulb (max. 100 watts each), Genie LED light bulb recommended |

Loading...

Loading...