SV200 R200

4/2007© by GLOBAL GARDEN PRODUCTS

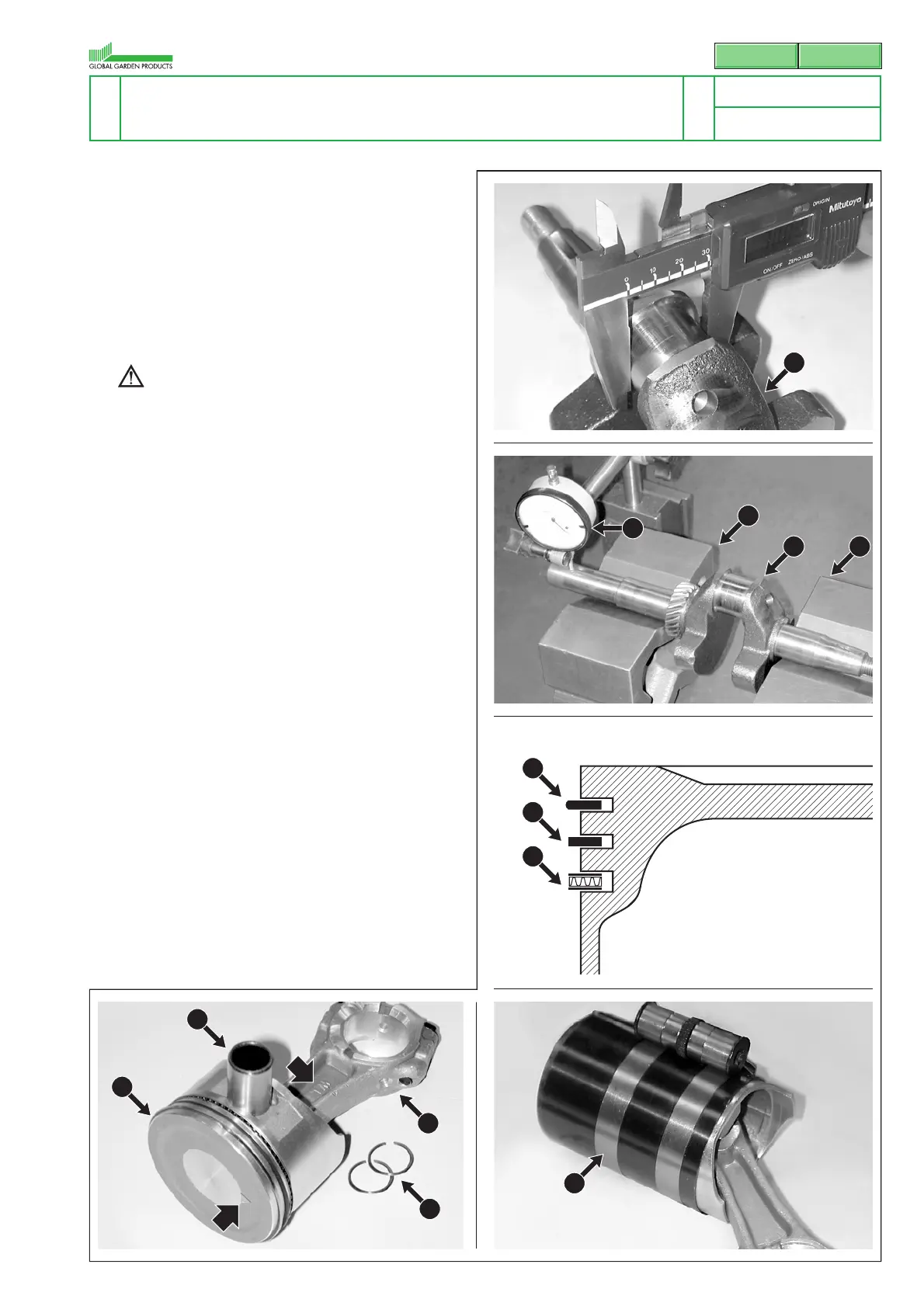

58 To check the alignment between the manifolds

and the protruding part of the shaft, place the

engine shaft on two prismatic guides (53) and,

with the help of a comparator (59) placed at the

end, check the displacement by rotating the

shaft. The shaft must be replaced if the dis-

placement exceeds 0.15 mm.

IMPORTANT - A bent shaft must never be

repaired!

WARNING – A bent shaft causes abnormal

vibrations and could be dangerous when the

machine is used!

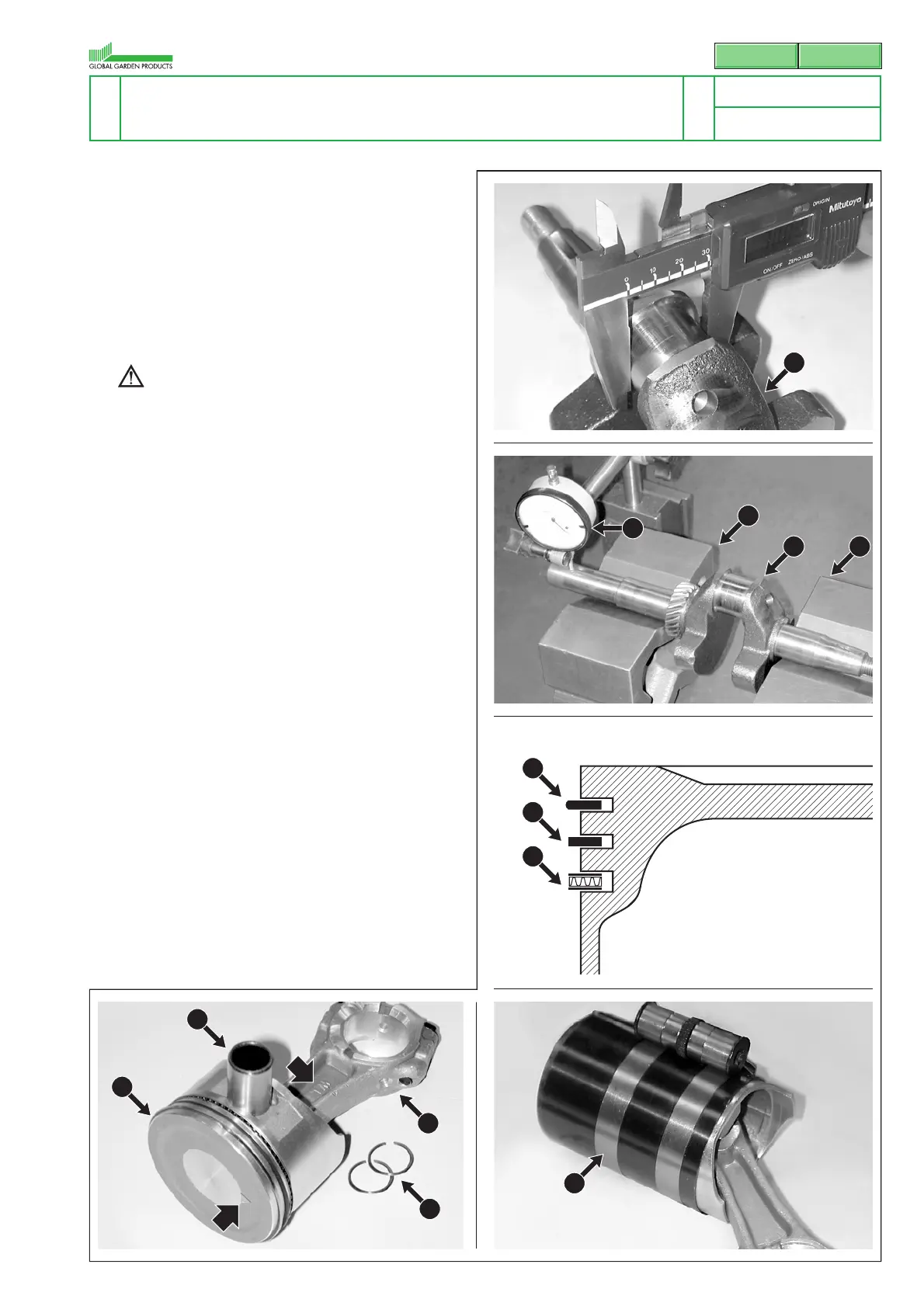

59 To refit the rings to the piston, first fit the three

oil scraper rings (55), then the ring with a round

edge (56) and finally the ring with a sharp edge

(57), being careful over the markings (which

must face the piston head) and in arranging the

gaps to ensure that they are not aligned with

each other.

60 Fit the connecting rod (42), gudgeon pin (51)

and clamping rings (50) to the piston (44), taking

care over the connecting rod marking, which

must face the outlet side of the engine shaft,

with the piston marking facing the exhaust.

61 Put the piston into the ring compression tool

(58).

62 Oil the inside of the piston liberally and insert

the piston, with the marking facing the exhaust.

63 Refit the engine shaft (52) taking maximum care

to match up the two references (59) and (60)

punched on the gears, so as to ensure correct

distribution phasing.

6.10.1

ENGINE BLOCK – Overhauling internal parts

6 / 7

SERVICE MANUAL

page

from

2007 to ••••

52

53

5352

54

58

42

51

50

44

57

56

55

Loading...

Loading...