SV200 R200

4/2007© by GLOBAL GARDEN PRODUCTS

19 Carry out a spark test as described in point “A”:

– If the spark jumps = the coil functions cor-

rectly, so if the system malfunctions, it is due

to the earth microswitch or relative cable

[

6.7.B];

– if the spark does not jump = the coil is faulty

and must be replaced [

6.6.C].

20 Remount the conveyor (10).

21 Remount the tank [

6.1.A

].

22 Remove the starting system [

6.2.A].

C) Replacing the coil

31 Remove the starting system [ 6.2.A].

32 Remove the tank [

6.1.A

].

33 Remove the conveyor (10).

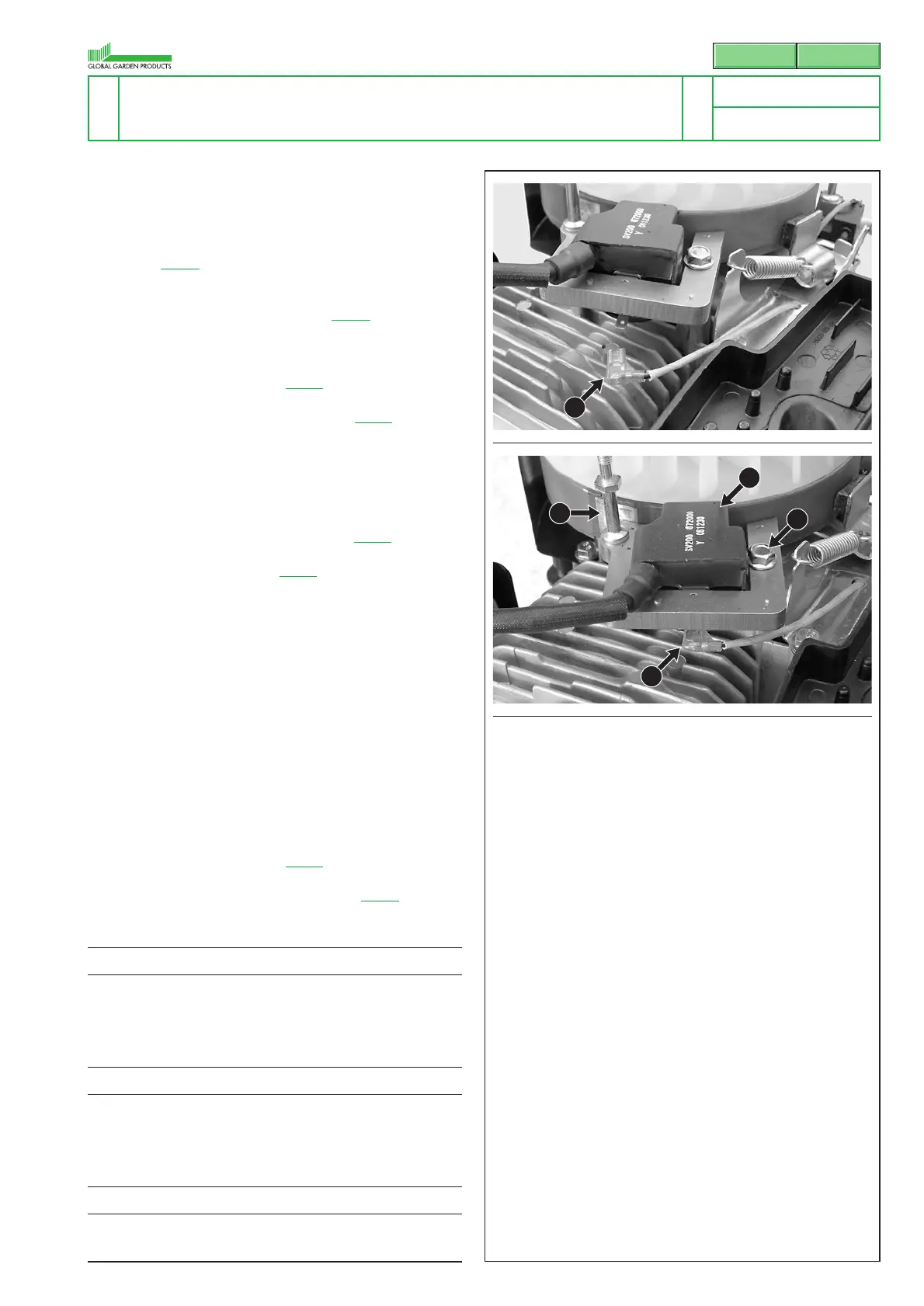

34 Disconnect the faston of the earth cable (11).

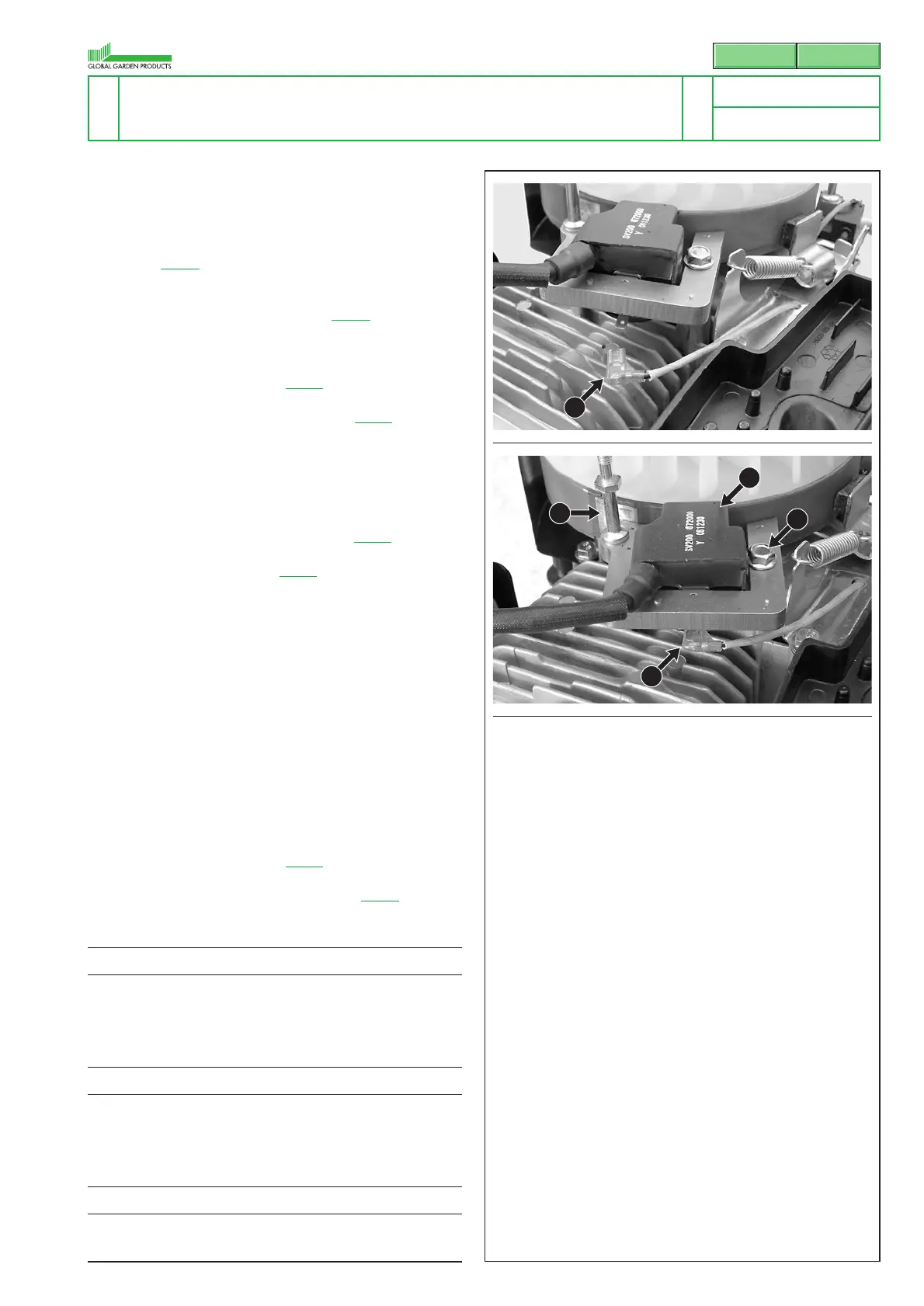

35 Unscrew the screw (14) and stud bolt (15) and

remove the coil (12).

36 Fit the new coil and adjust the air gap as

described in steps 14 - 15 of the procedure

described in point “B”.

37 Connect the faston of the earth cable (11).

38 Remount the conveyor (10).

39 Remount the tank [

6.1.A].

40 Remount the starting system [

6.2.A].

Tightening torques

1

Spark plug tightening torque ............ 16-18 Nm

14 Coil fixing screw ................................. 8-10 Nm

15 Coil fixing stud bolt ............................ 8-10 Nm

Technical information

Type of spark plug ...... RN9YC (Champion) or equivalent

Distance between electrodes .............. 0.6-0.8 mm

Coil/flywheel air gap ........................ 0.25-0.40 mm

Special equipment

3

Tester for spark test

6.6.1

IGNITION SYSTEM

3 / 3

SERVICE MANUAL

page

from

2007 to ••••

11

11

14

15

12

Loading...

Loading...