17

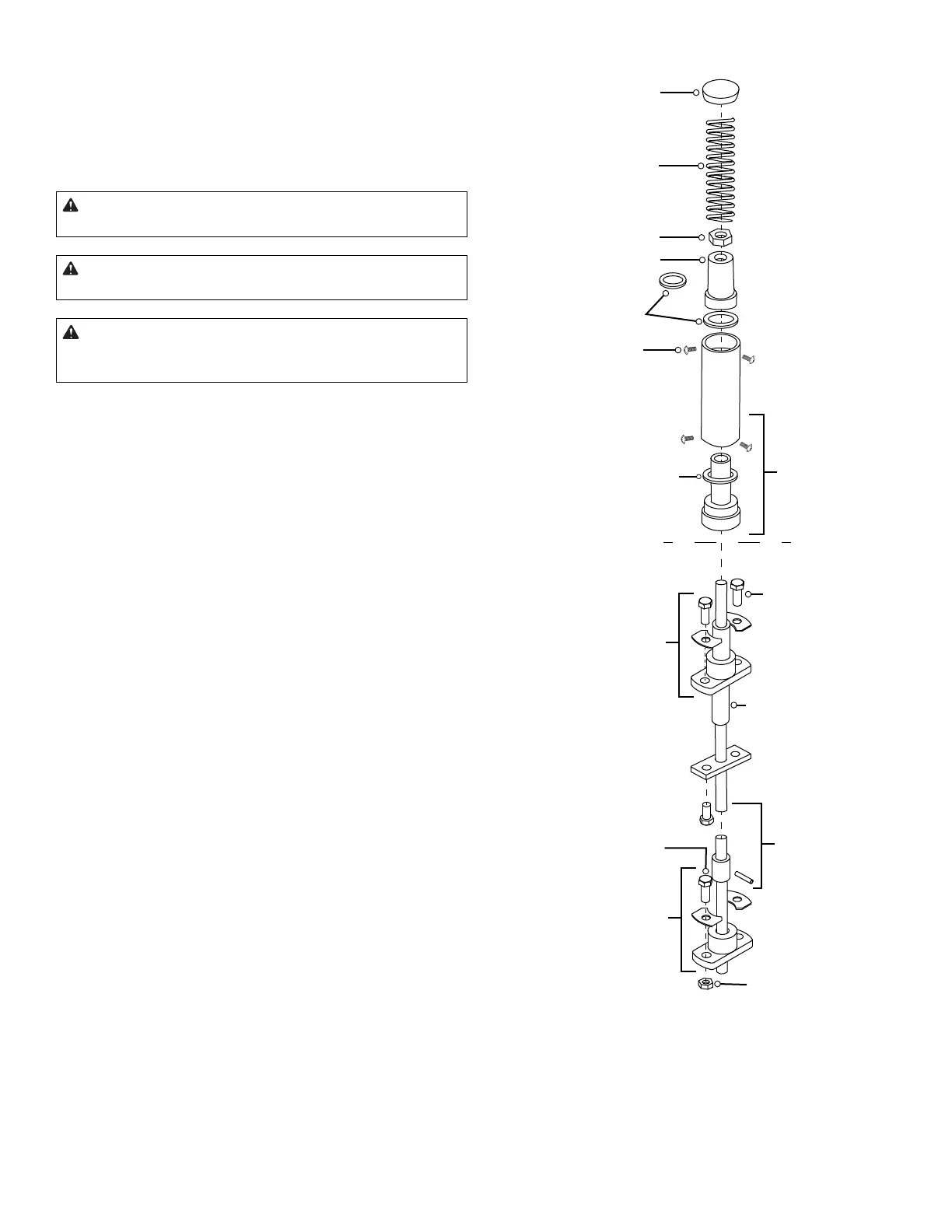

Hydraulic Cylinder Inspection and Repair

The hydraulic cylinders apply force to the clamp rods,

which draw the Vibrating Unit Assembly parts together�

If the machine loses clamping pressure during operation,

and/or if hydraulic oil must be frequently added, inspect the

hydraulic cylinders for wear�

Disconnect power supply before

servicing or cleaning.

DO NOT plug in or operate the

Testing Screen without all covers installed.

When working with the hydraulic

cylinders, take care NOT to score surfaces where

seals must be maintained.

To inspect a hydraulic cylinder for wear:

1. Unplug or otherwise disconnect the Testing Screen from

its power source, and lock out the connection�

2. Drain the hydraulic system. See Draining and Relling

the Hydraulic System on page 14�

3. Remove the three screws securing the cylinder cap

(Fig� 8)� The spring is compressed inside the cylinder by

the cap, so caution is required� Keep pressure on the

cap with your hand as you remove the three screws�

4. Release the pressure on the cap slowly so that the

compressed spring does not eject suddenly� Remove the

cap and spring�

5. Remove the side access panel near the machine’s base�

6. Grasp the lower section of hydraulic clamp rod with vice

grips and hold it steady while unscrewing the clamp rod

hex jam nut�

7. Pull the rest of the cylinder up and o the clamp rod.

8. Examine the piston and the two quad rings: One ts in a

groove on the piston ange, and the other ts inside the

piston. Replace the quad rings if you nd hydraulic oil

above the ange on the piston.

NOTE: It should NOT be necessary to disassemble the

cylinder from its base� Cylinder O-rings rarely need

to be replaced�

9. If cylinder O-ring replacement is necessary, use a 3/16in

drift punch to drive each of the roll pins through to the

center hole until they fall out� Remove the old O-ring�

Apply a small amount of hydraulic oil to the new O-ring,

and install it� Reassemble�

Cylinder Cap

Spring

Quad Ring Set

Cylinder O-ring

Clamp Rod

Hex Jam Nut

Hydraulic Cylinder

Piston

Cylinder Cap

Screws

Cylinder Base/

Sub-assembly

Upper Guide

Bearing Assembly

Upper Guide

Bearing Screw

Upper Guide

Bearing Sleeve

Hydraulic Clamp

Rod Collar

and Pin

Lower Guide

Bearing Assembly

Lower Guide

Bearing Screw

Lower Guide

Bearing Stop Nut

Fig. 8: TS-1 and TS-3 Hydraulic Cylinder

Loading...

Loading...