Page 11

CONNECT MODULE

The Pro Series CONNECT Module is a

separately sold accessory that will allow the

user to stay connected and receive remote

needed maintenance while away from home.

Pro Series WiFi Module (Model PS-WiFi2)

•

and status alerts to your phone, tablet or

computer

• No required monthly or yearly fees or

subscriptions

Model PS-WiFi2

For more information, please visit

www.StopFlooding.com

TESTING THE FLOAT SWITCH

FOR THE BACKUP PUMP

It is important to manually test the oat

switches periodically or after any maintenance.

!

DANGER

Unplug the main AC pump when installing

or servicing the backup pump to avoid

electric shock. Failure to do so could cause

serious injury or death. Review the safety

instructions on page 2.

nonmetallic item, and let go. This will activate

the pump. The control unit will run the pump

for approximately 25 seconds so it can empty

all the water in the sump pit. If no water is in

the pit, the pump can run dry for this amount

of time. The alarm will sound and the “Pump

was activated” light will go on. After the

pump has stopped, push the RESET button

to silence the alarm. If the RESET button is

pressed before the pump has stopped, the

alarm will go off temporarily. Wait for the

pump to stop pumping, and then push the

RESET button on the front of the control unit

to completely silence the alarm.

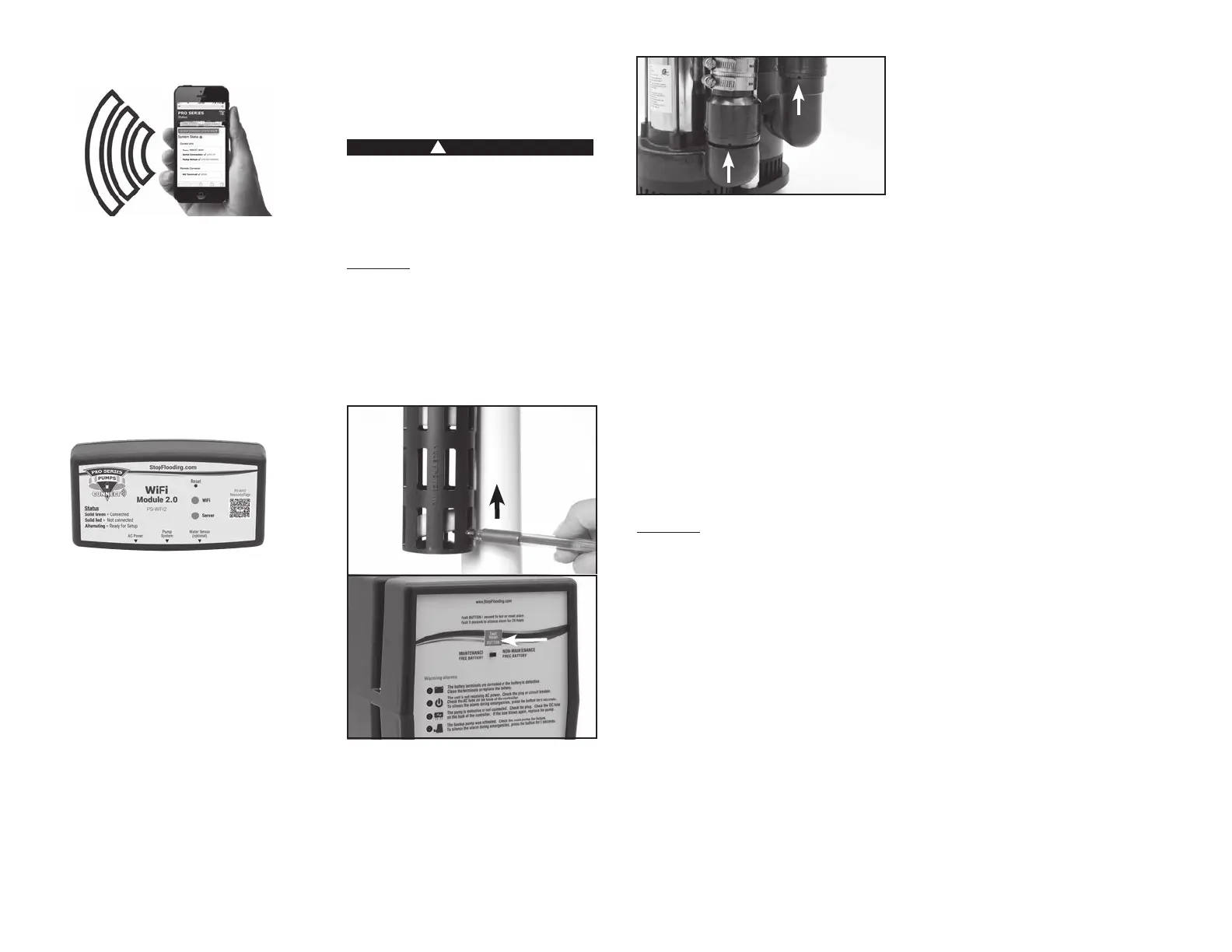

While the pumps are active, water will come

valve above the pump. This is normal. The

hole is needed to prevent an air lock within

the system. DO NOT obstruct this hole or an

air lock may prevent the pump from activating,

BE SURE TO PLUG IN THE MAIN AC PUMP

WHEN YOU HAVE COMPLETED THE TEST.

TESTING THE FLOAT SWITCH

FOR THE PRIMARY PUMP

nonmetallic item, and let it go to activate the

pump. The pump will run an additional 10

position. It will not damage the pump to run

it for this short time if the sump pit is dry.

However, DO NOT

extended time without water in the sump pit.

While the pumps are active, water will come

valve above the pump. This is normal. The

hole is needed to prevent an air lock within

the system. DO NOT obstruct this hole or an

air lock may prevent the pump from activating,

MAINTENANCE CHECKLIST

Maintenance should be performed 1-2 times

per year.

1.

described to the left.

2. Remove all debris from the bottom of the

pit and pump strainer.

3.

4.

cage.

5. Fill the pit with water. Make sure the

pumps turn on at the intended levels.

6. While the pump is running, make sure

the pump is evacuating water at a good

air bleed hole.

7. Check and clean battery and terminals.

PARTS & SERVICE INFORMATION

You can receive technical support, parts, or

service information by calling Glentronics,

Inc., at 800-991-0466 or by visiting the Pro

Series website at www.stopooding.com.

Send your unit to the following address if

repairs are needed:

Glentronics, Inc.

Attn: Service

645 Heathrow Drive

Lincolnshire, IL 60069-4205

Lift

Float

Loading...

Loading...