19

o8) Using a 1/16” drill bit, drill a hole

through the side of the fuselage for the an-

tenna to exit. Route the antenna out the fuse-

lage and secure it to the vertical fin using a

rubber band. See figure # 9 below.

Figure # 9

PARTS REQUIRED

THROTTLE LINKAGE

INSTALLING THE THROTTLE CONNECTOR

o {1} Adjustable Servo Connector Assembly

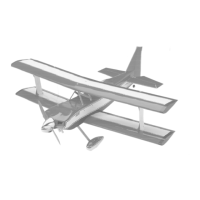

o 1) Install one adjustable servo connector

through the second hole out from the center

of one servo arm. You may have to enlarge

the hole in the servo arm to accommodate the

servo connector. Remove the excess material

from the servo arm using wire cutters. See

figure # 10 below.

Figure # 10

After installing the adjustable servo con-

nector apply a small drop of Kwik Bond

Thin C/A to the nut. This will prevent the

connector from loosening during flight.

o 2) Turn on the radio system. Check to

ensure that the throttle servo output shaft is

moving in the correct direction.

o 3) Slide the adjustable servo connector/

throttle arm assembly over the end of the throttle

pushrod wire. Position the throttle stick and

the throttle trim at their lowest positions.

o 4) Manually push the carburetor barrel

fully closed. Attach the servo arm to the servo

angled back about 45º from center. With the

carburetor barrel fully closed, tighten the set

screw in the adjustable servo connector.

o 5) Remove the excess throttle pushrod wire

using wire cutters. See photo # 33 below.

Photo # 33

o 6) Test the movement of the throttle

pushrod. Full forward stick and full forward

trim should result in the carburetor barrel

opening completely. Full down stick and full

forward trim should result in the approximate

idle setting. Full down stick and full down

trim should result in the carburetor barrel clos-

ing fully.

o 7) When satisfied that the pushrod link-

age is adjusted correctly and no binding is

present, install the servo arm set screw.

PARTS REQUIRED

RUDDER PUSHROD

INSTALLING THE RUDDER CONTROL HORN

o {1} Nylon Control Horn w/Nylon Back Plate

o {2} 2mm x 15mm Machine Screws

o {1} 700mm Nylon Pushrod

o {1} 2mm x 120mm Wire Threaded Both Ends

o {1} 2mm x 85mm Threaded Wire w/L-Bend

o {1} Nylon Snap Keeper

o {1} Nylon Clevis

o {1} Pushrod Support (D-32)

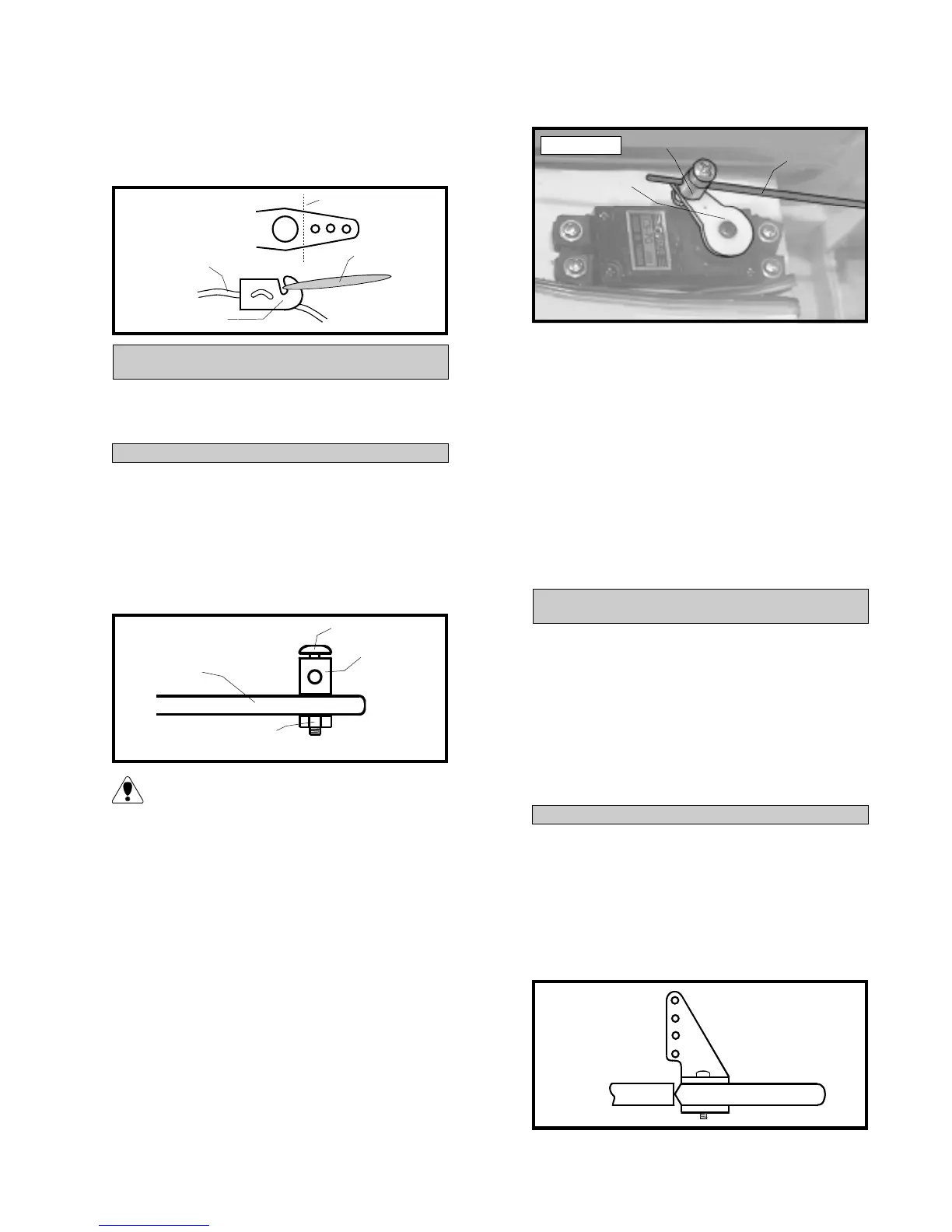

o 1) The centerline of the rudder control horn

is located on the left side of the rudder (looking

from behind) 1-3/8” up from the bottom of the

rudder. Position the control horn so the clevis

attachment holes are directly in-line with the

hinge line. The control horn should also be par-

allel with the hinge line. See figure # 11 below.

Figure # 11

CUT

RUBBER

BAND

MODIFIED SERVO

ARM

ANTENNA

SERVO ARM

NUT

SET SCREW

SERVO

CONNECTOR

PUSHROD

WIRE

SERVO

ARM

CONNECTOR

Loading...

Loading...