21

PARTS REQUIRED

ELEVATOR PUSHROD

INSTALLING THE ELEVATOR CONTROL HORNS

o {2} Nylon Control Horns w/Nylon Back Plates

o {4} 2mm x 15mm Machine Screws

o {2} 600mm Nylon Pushrods

o {2} 2mm x 100mm Wire Threaded Both Ends

o {3} Nylon Clevises (one w/1.5mm I.D. Hole)

o {1} Nylon Joiner Plate

o {2} 2.2mm x 10mm Wood Screws

o {4} 2mm Flat Washers

o {1} 2mm x 20mm Machine Screw

o {1} 2mm Hex Nut

o {1} Pushrod Support (D-32)

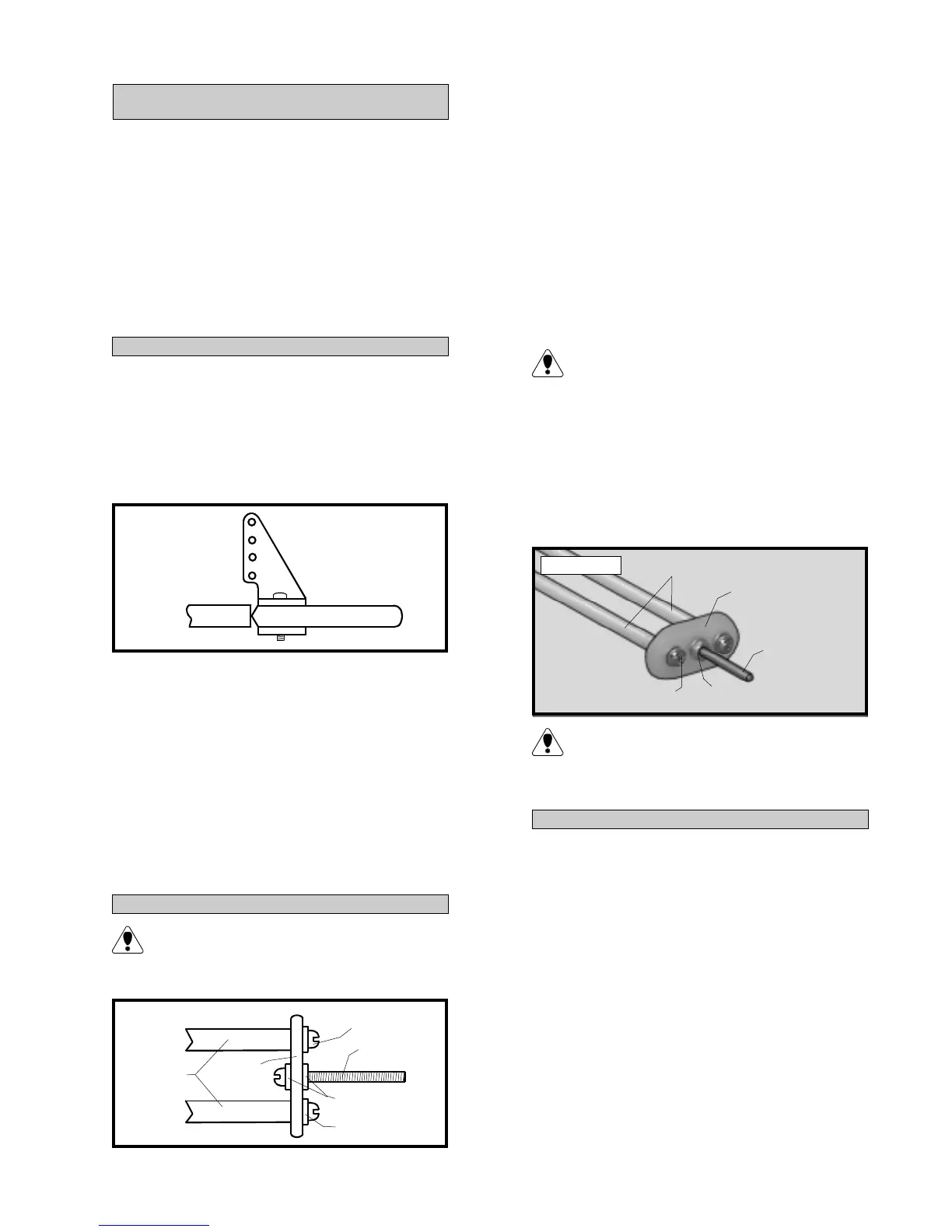

o 1) The centerline of the elevator control

horns are located on the bottom side of each

elevator half, 1” out from the fuselage sides.

Position the control horns so the clevis attach-

ment holes are directly in-line with the hinge

line. The control horns should also be parallel

with the hinge line. See figure # 12 below.

Figure # 12

o 2) When satisfied with the alignment, use

a 3/32” drill bit and the control horns as a guide

and drill the mounting holes through the el-

evator halves.

o 3) Mount the control horns to the eleva-

tor halves by inserting the 2mm x 15mm ma-

chine screws through the control horn mount-

ing bases, through each elevator half and into

the backplates. Tighten the screws, but do not

overtighten them. You do not want to crush

the wood.

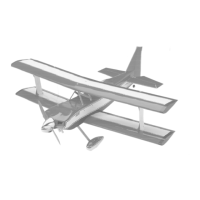

INSTALLING THE PUSHROD JOINER

The elevator control system uses two

pushrods which are connected together

just before they reach the elevator servo. See

figure # 13 below.

Figure # 13

o 4) Using a 3/32” drill bit, drill a hole

through the center of the nylon joiner plate.

Slide a 2mm washer onto the 2mm x 20mm

machine screw. Slide the screw through the

center hole of the nylon joiner plate.

o 5) Slide a second 2mm washer onto the

machine screw and then thread on the 2mm

nut. Tighten the nut completely and secure it

in place using Kwik Bond Thin C/A. Let the

C/A cure completely and double check to en-

sure the screw and nut do not move.

We don't recommend using any types of

thread lock or C/A accelerators. The

chemicals in these items can destroy the ny-

lon parts.

o 6) Slide one 2mm washer over two

2.2mm x 10mm wood screws. Slide the wood

screws through the two outer holes in the ny-

lon plate and thread them into the two 600mm

nylon pushrods. See photo # 36 below.

Photo # 36

We highly recommend installing the two

wood screws using Kwik Bond 5 Minute

Epoxy to help prevent any possible chance of

them pull out during flight.

o 7) Thread one nylon clevis with 1.5mm

I.D. hole onto the end of the 2mm x 20mm

machine screw.

o 8) Using a modeling knife remove the

covering from over the two elevator pushrod

exit slots. Looking from the back of the air-

plane, the slots are located on each side of the

fuselage, 6” forward of the rudder hinge line

and 1” below the horizontal stabilizer.

o 9) Using a ruler and pen, measure for-

ward on both pushrod housings 4” from

where the pushrod housings enter the servo

compartment from the rear bulkhead.

INSTALLING THE ELEVATOR PUSHROD

PUSHROD

TUBES

2mm x 20mm

MACHINE SCREW

2mm WASHER

2.2mm x 10mm

WOOD SCREW

2mm

WASHER

NYLON

PLATE

PUSHROD

TUBES

NYLON

PLATE

MACHINE

SCREW

WOOD

SCREW

NUT

Loading...

Loading...