16

o2) Mix up a small amount of Kwik Bond

5 Minute Epoxy. Use a couple of small dabs

of epoxy to glue the balsa gear cover (D-29)

onto the aluminum gear, flush with the bot-

tom of the fuselage.

There are three holes predrilled through

the block that allow the screws to be re-

moved should the gear need servicing. You

can leave these holes covered by the covering

or remove the covering from over them now

using a modeling knife.

INSTALLING THE WHEEL PANTS

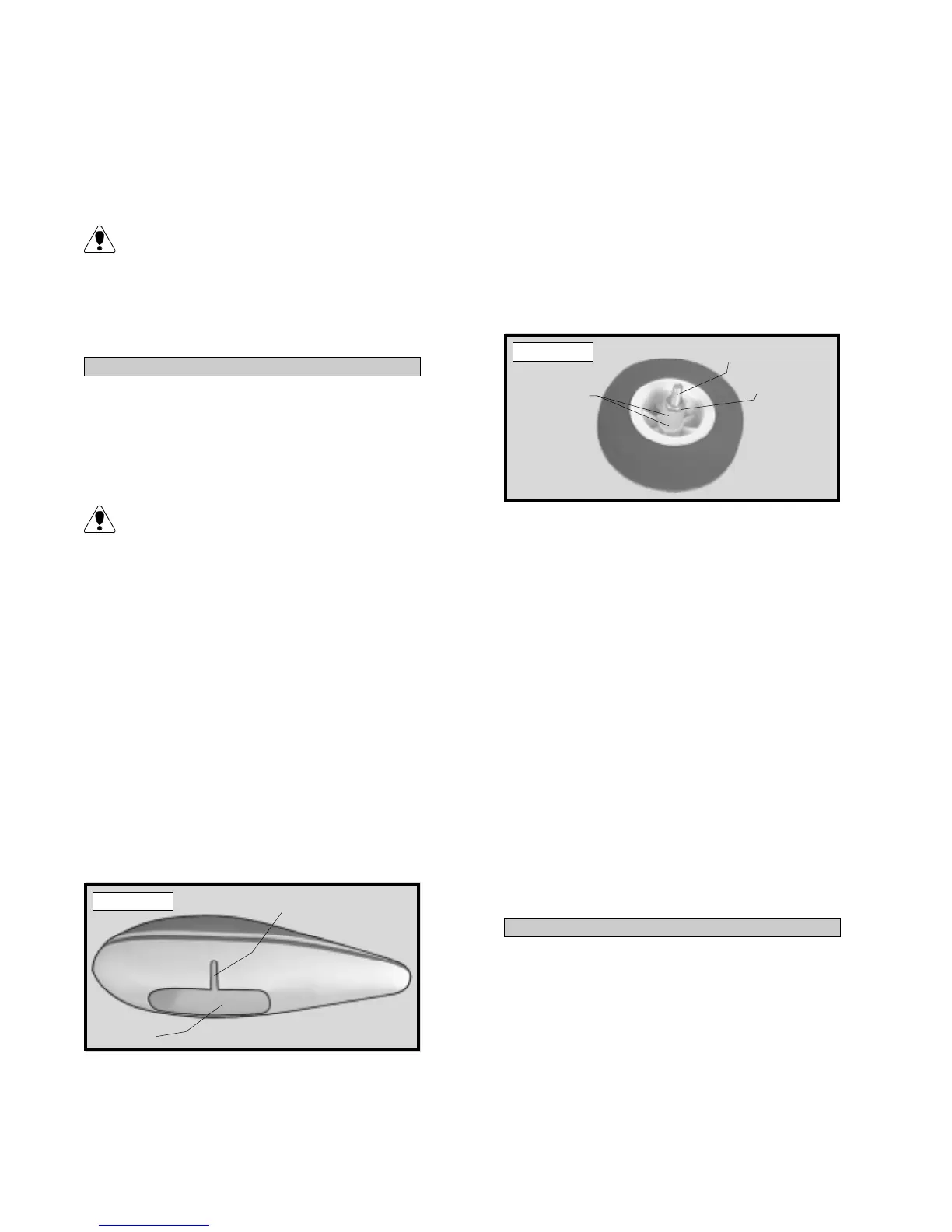

o 1) Working with one wheel pant at a time,

use a Dremel Tool and remove the plastic that

covers the wheel opening on the bottom of

the wheel pant.

Look carefully at each side of the wheel

pant and you will notice a molded dimple.

One dimple is about 1/8” higher on one side

than the other. If you will be flying off a hard

surface we recommend you drill out the dimple

that is higher. If flying off of grass we rec-

ommend you drill out the dimple that is lower.

This will raise the wheel pant higher on the

axle and give more clearance between the

wheel pant and the ground.

o 2) Using a 5/32” drill bit, drill out only

the one dimple that you choose.

o 3) Using a modeling knife, cut a slot from

the hole down to the wheel pant opening. See

photo # 26 below.

Photo # 26

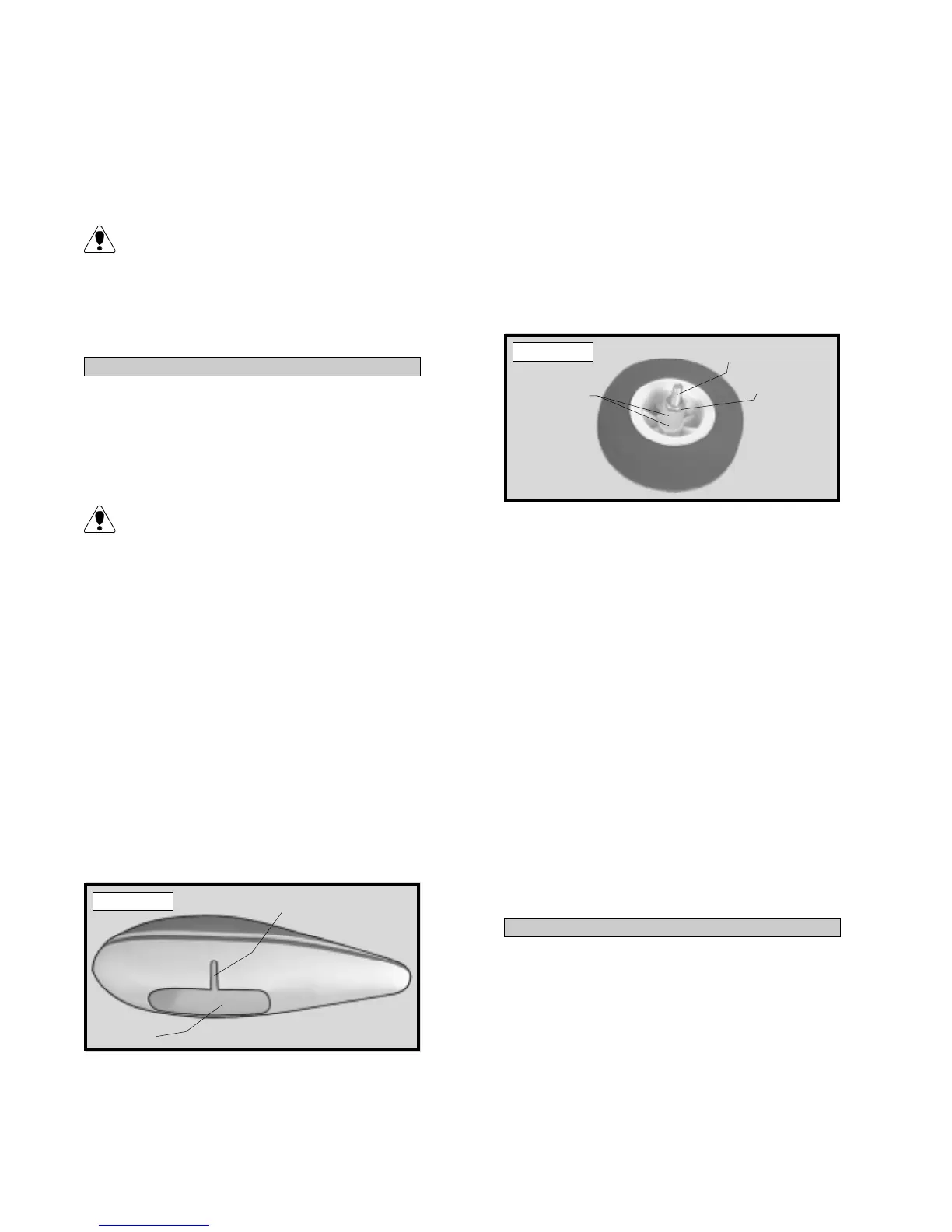

o 4) Slide one 60mm diameter wheel onto

one 4mm x 35mm axle screw. The wheel

should go on with flat side of the hub first.

o 5) Slide two 4mm nylon spacers over the

axle screw and up against the wheel. Thread

one 4mm hex nut onto the axle screw.

o 6) Tighten the hex nut against the nylon

spacers as tight as it can be, but still allow

the wheel to spin free on the axle. Secure

the nut in place by carefully applying a couple

of drops of Kwik Bond Thick C/A to the

threads. Allow the C/A to fully cure. See

photo # 27 below.

Photo # 27

o 7) Slide one 4mm washer over the axle

screw and up against the hex nut. Carefully

slip the wheel and axle assembly into the

wheel pant. The axle screw should slip firmly

into the slot in the wheel pant and the flat

washer should be positioned inside the wheel

pant.

o 8) Slide the axle bolt through the pre-

drilled 4mm hole in the aluminum gear

bracket and secure in place using one 4mm

lock nut. Tighten the lock nut completely,

at the same time making sure the hex nut does

not come loose. Double check that the wheel

does not bind when rotated.

o 9) Repeat steps # 1 - # 8 for the opposite

side.

ADJUSTING THE WHEEL PANTS

o 10)With both wheels and wheel pants in-

stalled on the gear bracket, set the airplane on

it's wheels on a level surface. Adjust the wheel

pants so the rear portion of the wheel pant is

level with the ground. Double check that both

wheel pants are level with each other.

CUT SLOT

REMOVE

COVER

AXLE SCREW

NYLON

SPACERS

HEX NUT

Loading...

Loading...