5

**SUGGESTION** To avoid scratching or damaging your new airplane, do not unwrap the pieces until

they are needed for assembly. Cover your workbench with an old towel or brown paper, both to protect

the aircraft and to protect the table. Keep a couple of jars or bowls handy to hold the small parts after you

open the bags.

**NOTE** Please trial fit all the parts. Make sure that you have the correct parts and that they fit and are

aligned properly before gluing! This will ensure proper assembly. Since the Ultimate Biplane is hand

made from natural materials, every plane is unique and minor adjustments may have to be made. How-

ever, you should find the fit superior and assembly simple.

If you should find a part missing or have questions about assembly, please call or write to the address

below:

Customer Service Center

18480 Bandilier Circle

Fountain Valley, CA. 92728

Phone: (714) 963-0329

Fax: (714) 964-6236

E-Mail: globalhobby@earthlink.net

PARTS REQUIRED

BOTTOM WING MOUNTING

ALIGN THE BOTTOM WING

o {1} Bottom Wing w/Ailerons & Hinges

o {1} Wing Bolt Doubler (W-24)

o {2} 4mm x 25mm Machine Screws

o {2} 4mm Washers

o {2} 4mm Blind Nuts

o 1) Place the wing into the wing saddle

making sure that the preinstalled dowel in the

leading edge of the wing fully engages the

predrilled hole in the forward bulkhead in the

fuselage. Push the wing as far forward as

possible. The leading edge should fit tight

against the bulkhead.

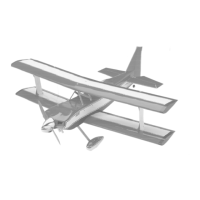

o 2) Using a ruler and pen, measure and

place a mark on the centerline of the bottom

of the fuselage at the rear of the wing saddle.

Also measure and place a mark at the

centerline of the wing at the trailing edge. See

photo # 1 below.

Photo # 1

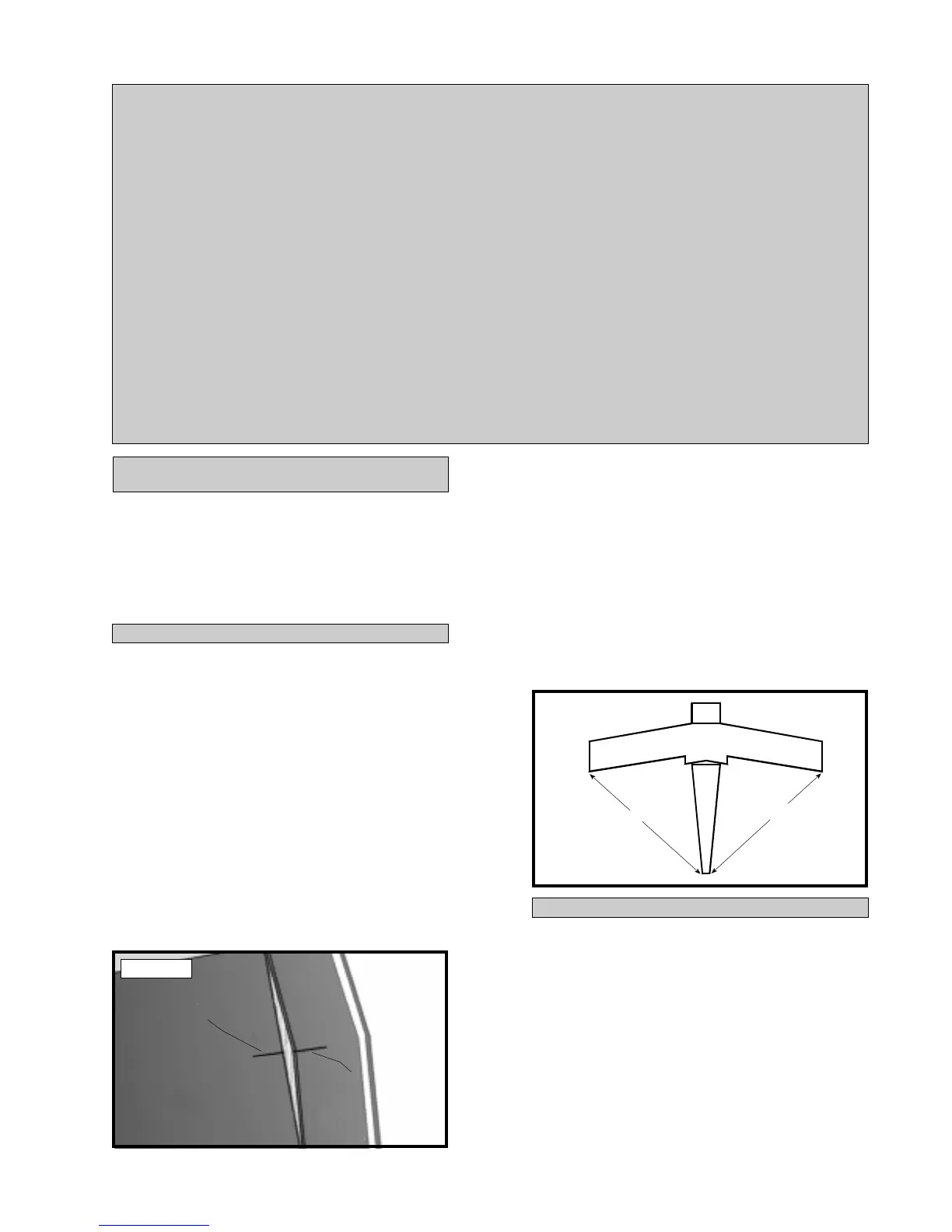

o 3) With the wing in the wing saddle, align

the two marks and hold the wing securely in

place using a couple of pieces of masking tape.

o 4) Remove the ailerons from the wing.

To double check that the wing is square to

the fuselage, use a ruler and measure from

each wing tip to the rear edge of the fuse-

lage. Both measurements should be equal.

See figure # 1 below.

Figure # 1

o 5) When satisfied with the alignment, use

a 5/32” drill bit and drill two holes through the

wing and on through the plywood wing hold

down block. The holes are located 1-1/2” out

from the centerline and 1/2” forward of the trail-

ing edge.

INSTALLING THE BLIND NUTS

A

A1

A=A1

DRAW CENTERLINE

DRAW CENTERLINE

Loading...

Loading...