20

o4) Thread the 2mm x 120mm threaded

wire into one end of the 700mm nylon

pushrod. For safety, thread the wire no less

than 5/16” into the pushrod.

o 5) Thread the nylon clevis onto the op-

posite end of the 2mm x 120mm threaded wire.

It should be threaded no less than 5/16” onto

the wire also.

o 6) Using a modeling knife remove the

covering from over the rudder pushrod exit

slot. Looking from the back of the airplane,

the slot is located on the left side of the fuse-

lage, 6” forward of the rudder hinge line and

1-1/4” below the horizontal stabilizer.

o 7) Insert the plain end of the nylon

pushrod into the fuselage from the back. Snap

the clevis onto the rudder control horn. Move

the rudder back and forth to ensure there is no

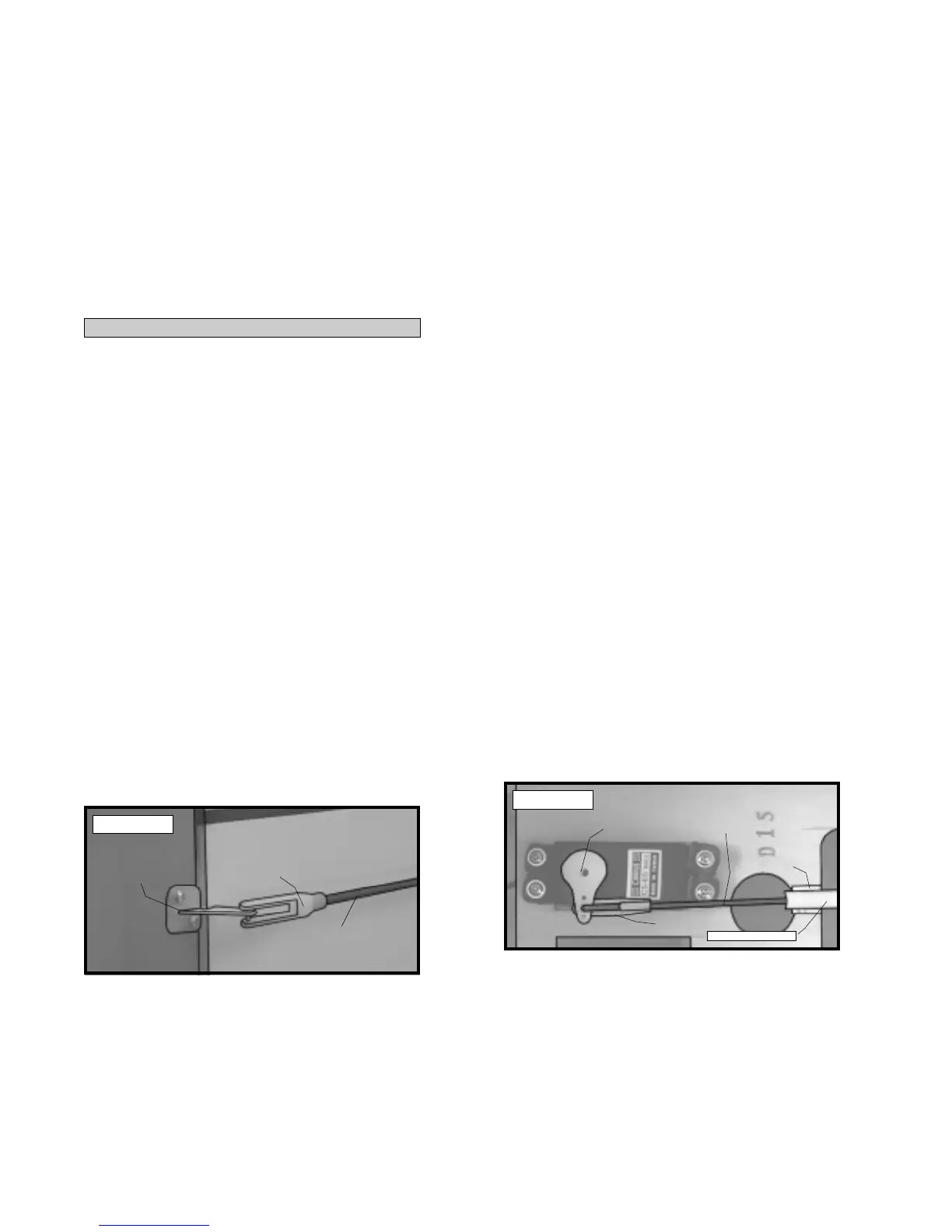

binding. See photo # 34 below.

o 2) When satisfied with the alignment, use

a 3/32” drill bit and the control horn as a guide

and drill the mounting holes through the rud-

der.

o 3) Mount the control horn to the rudder

by inserting the 2mm x 15mm machine screws

through the control horn mounting base,

through the rudder and into the backplate.

Tighten the screws, but do not overtighten

them. You do not want to crush the wood.

INSTALLING THE RUDDER PUSHROD

Photo # 34

o 8) Remove the pushrod from the pushrod

housing. Using a ruler and pen, measure for-

ward on the pushrod housing 4” from where

the pushrod housing enters the servo compart-

ment from the rear bulkhead.

o 9) Using a modeling knife, cut off the

pushrod housing at this mark.

o 10) Slide the pushrod back into the

pushrod housing. Snap the clevis onto the rud-

der control horn and use a couple of pieces of

masking tape to hold the rudder in neutral.

o 11) Locate a long servo arm and using

wire cutters, remove all but one of the arms.

Install the L-bend in the 85mm wire into the

outer hole in the servo arm. Secure the wire

in place using one nylon snap keeper.

o 12) With the rudder and rudder servo in

neutral, install the servo arm onto the servo.

The arm should be positioned perpendicular

to the fuselage sides.

o 13) Using a pen, place a mark on the ny-

lon rudder pushrod where the tip of the wire

overlaps it. Use a modeling knife and cut off

the nylon pushrod 5/16” ahead of the mark.

This will leave enough space so the threaded

wire can thread into the pushrod at least 5/16”.

o 14) Thread the wire into the pushrod.

You can thread it in further or back it out to

achieve the correct length.

o 15) When satisfied with the alignment,

install the servo arm set screw and remove the

masking tape from the rudder. See photo #

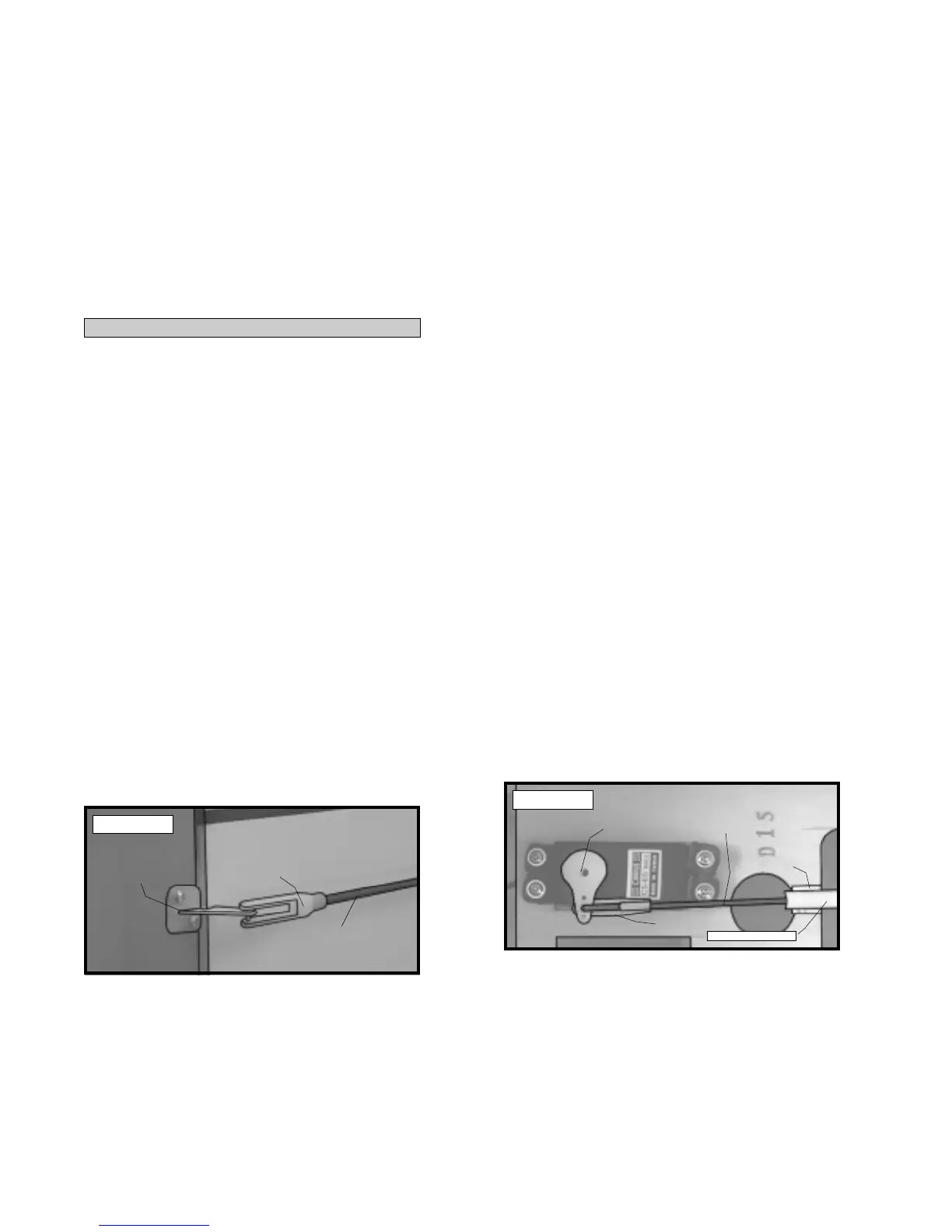

35 below.

Photo # 35

o 16) Move the rudder back and forth.

There may be some flex present in the pushrod

just before it gets to the rudder servo. If so,

glue one pushrod support (D-32) between the

pushrod housing and the servo tray using a

small amount of Kwik Bond 5 Minute Epoxy.

See photo # 35 above.

CONTROL

HORN

PUSHROD

WIRE

CLEVIS

SERVO

ARM

SNAP

KEEPER

PUSHROD

WIRE

PUSHROD

SUPPORT

PUSHROD HOUSING

Loading...

Loading...