Supplied By www.heating spares.co Tel. 0161 620 6677

9 Flue Preparation and Installation

9.18 Vertical flue

The vertical flue system is available as an option where the

boiler position does not permit the use of the top horizontal or

rear flue system.

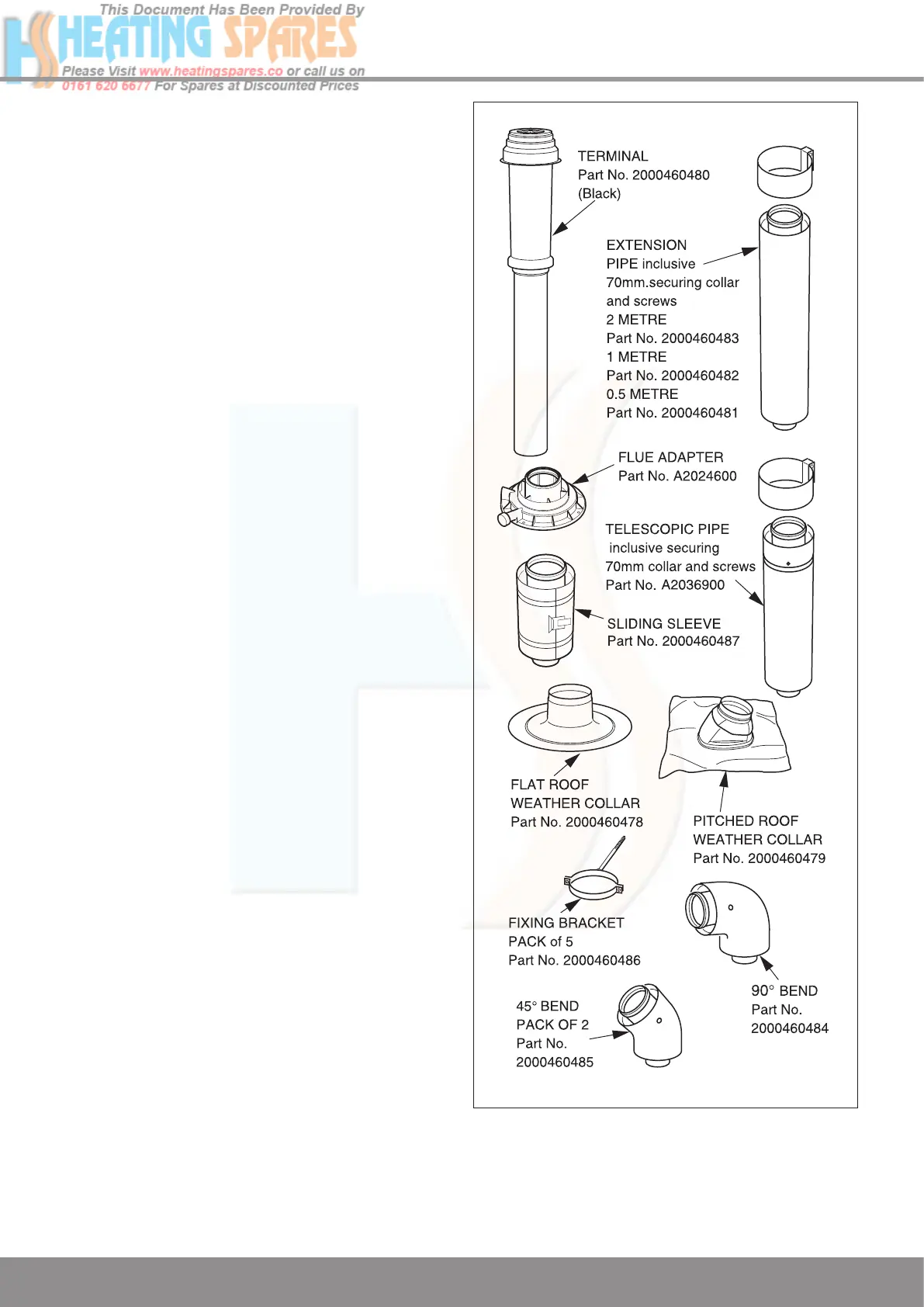

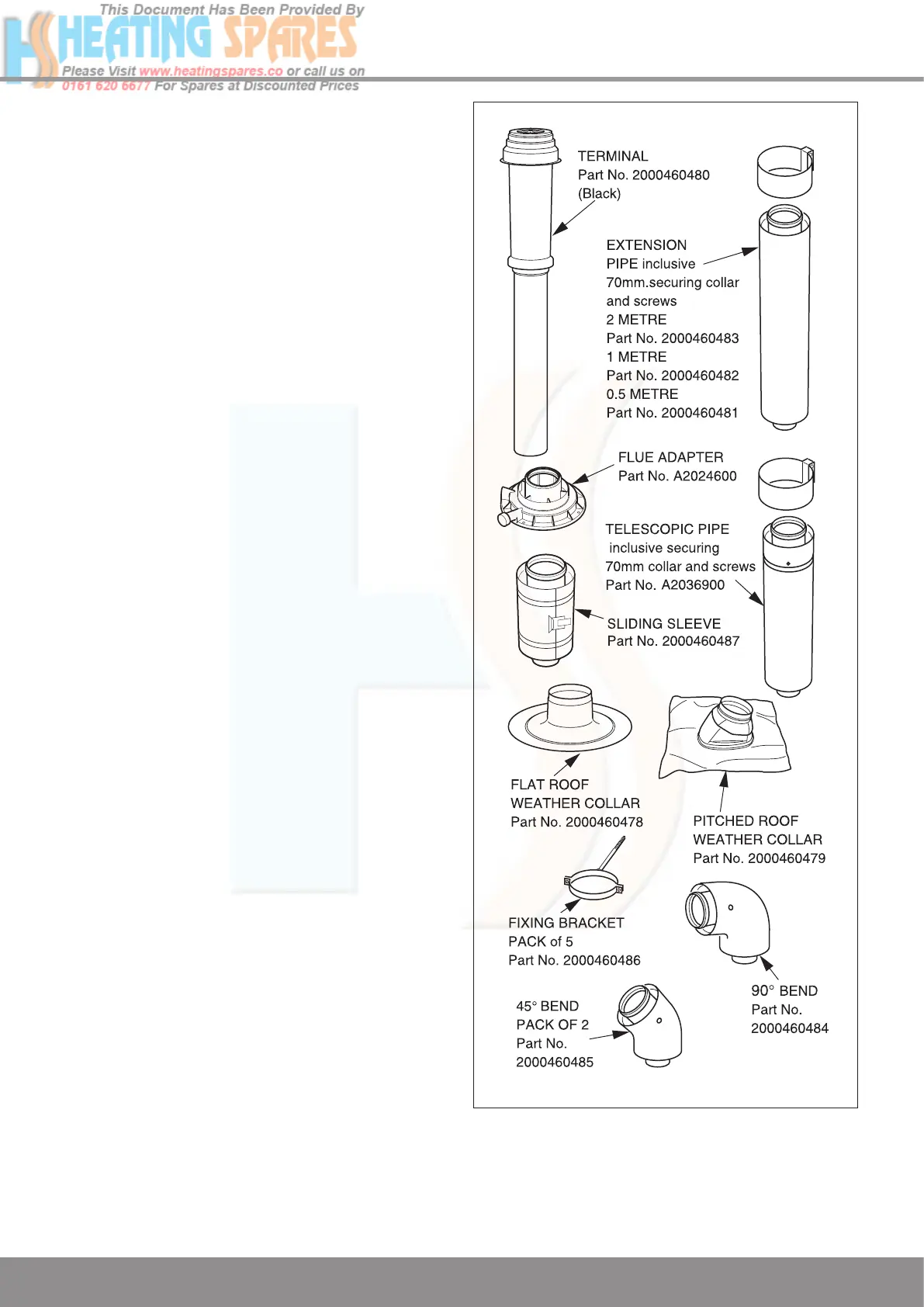

The system is made up of accessories. The accessories

include terminal assembly, bends 45º and 90º, flue

extensions, fixing bracket and appropriate weather collar, see

diagram 9.17.

The maximum permitted straight flue length is 8 metres plus

the terminal. for each 90

o

or 2x45

o

bends fitted, the maximum

length must be reduced by 1 metre, see diagram 9.22.

NOTE: 2x45º bends can replace 1x90º bend if necessary.

When using 90º bends any horizontal extension pipe should

be inclined by a minimum of 44mm/metre (2.5°) towards the

boiler to facilitate condense removal, see (a) in diagram 9.22.

Alternatively use 45º bends to avoid horizontal runs, see (b) in

diagram 9.22.

The terminal should be positioned at least 600mm from any

opening into the building, refer to diagram 3.2.

Measure the distance of fl

ue length required for the

installation.

The flue must be designed with a continuous fall towards the

boiler.

Remove the top flue outlet cover secured with four screws,

see diagram 9.2.

Refer to diagram 9.18. Secure the fl

ue adapter in position

on top of the boiler with four torx headed screws supplied,

making sure the nib fits into the locating slot in the boiler

casing to ensure correct orientation.

The rubber ‘O’ rings of each section should be lubricated prior

to assembly.

NOTE: Do not use mineral oils or grease, silicon grease or

water is recommended.

Secure the first extension pipe to the flue adapter with the

securing collar supplied by positioning the collar centrally over

the joint, then tighten the two screws on the securing collar

,

see diagram 9.19.

Fit more extension pipes as required using the collar and

screws supplied with each extension pipe. To fit position the

collar centrally over the joint, tighten the two screws on the

securing collar

. Using the holes provided in the securing

collar drill and insert the two self tapping srews supplied, see

diagram 9.20.

The rubber ‘O’ rings of each section should be lubricated prior

to assembly.

NOTE:

Do not use mineral oils or grease, silicon grease or

water is recommended.

When building the flue up it is recommended that it is

supported every 2 metres and at every bend by a fixing

bracket.

Project the rise of the flue pipe to roof level and cut a 150mm

hole in the roof.

12969

Diagram 9.17

Loading...

Loading...