24

221469B

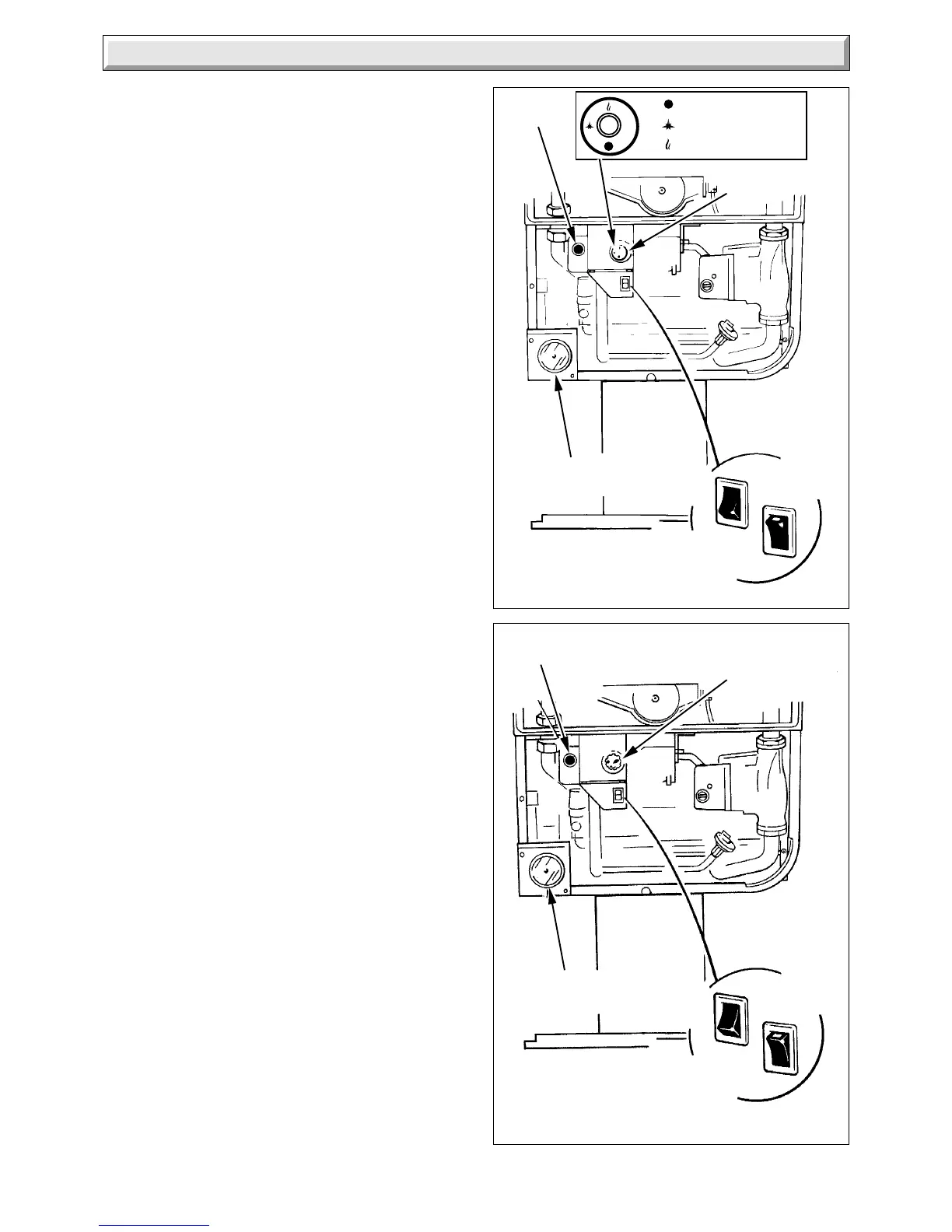

HONEYWELL

11 Commissioning

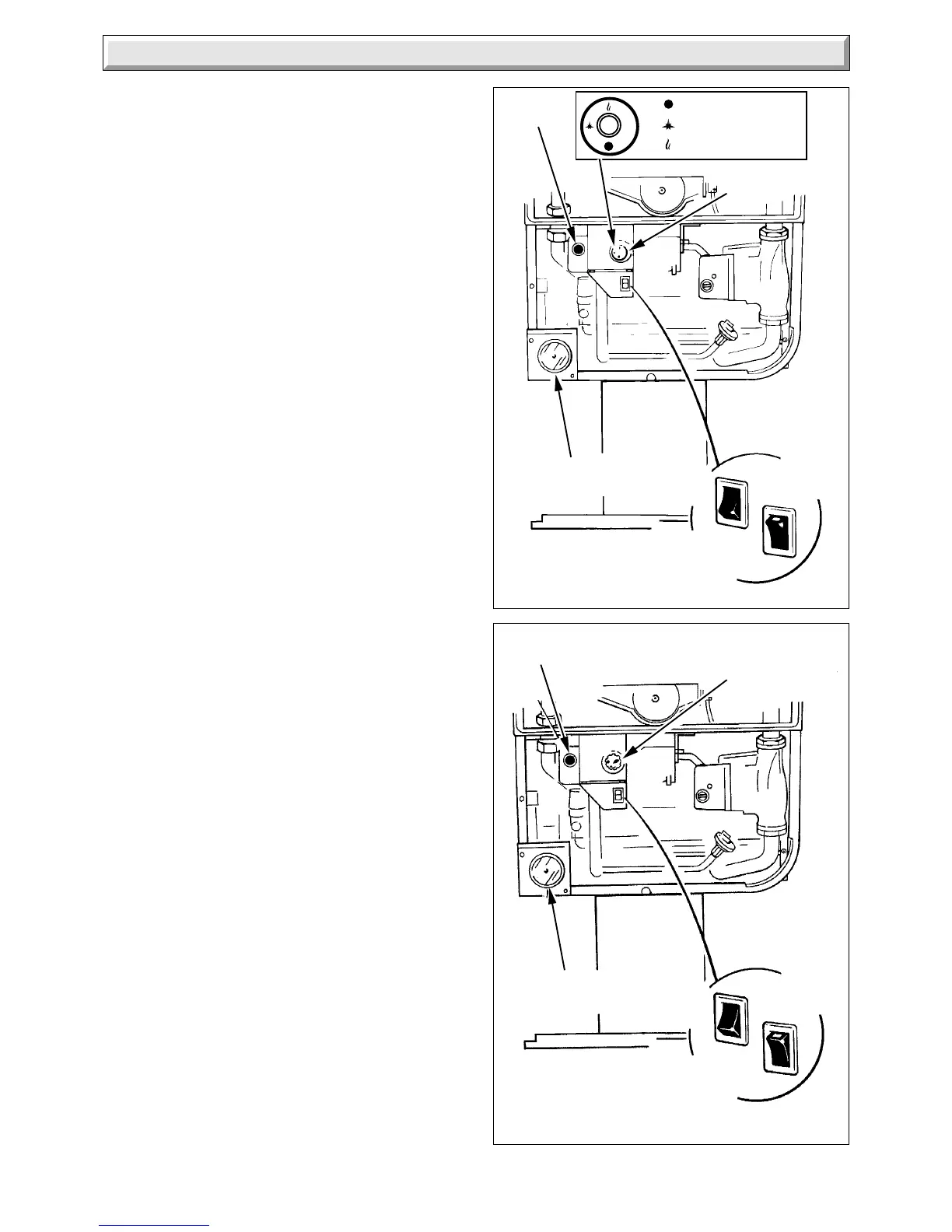

SIT

Diagram 11.1

4322

GAS CONTROL

KNOB 'D'

SWITCH

'ON'

SWITCH

(OFF)

PRESSURE

GAUGE 'A'

CENTRAL

HEATING

SELECTOR

SWITCH 'C'

Diagram 11.1

2834

SWITCH

'ON'

SWITCH

(OFF)

PRESSURE

GAUGE 'A'

CENTRAL

HEATING

SELECTOR

SWITCH 'C'

PIEZO

BUTTON 'E'

PIEZO

BUTTON

'E'

OFF

PILOT/IGNITION

MAIN BURNER

GAS CONTROL

KNOB 'D'

11.1 Filling Domestic Water Circuit

Check that the boiler is isolated from the electrical supply, at the

external isolator.

Fully open the domestic water supply stop cock or valve in the

supply to the boiler.

Open the two domestic water isolation valves, slots in line with

the length of the valve, see diagram 8.1.

Open all hot water draw-off taps and close them when water

flows. Check for water soundness of the whole domestic water

system and boiler.

11.2 Filling the Heating System

It is essential that a bypass is fitted in all installations, 22mm o.d.

minimum. The bypass must have a lockable valves “B” in

diagram 4.2, incorporated in a position so that inadvertent

closure or unauthorised interference is not possible.

The bypass MUST be fitted before any system control.

A radiator bypass is not recommended.

Open the two central heating isolating valves, slots in line with

the length of the valve, see diagram 8.1.

Flush, fill and vent the system refer to Section 4.9 “Filling Sealed

Systems”.

WARNING. SEVERAL COMPONENTS OPERATE ON MAINS

VOLTAGE AND WITH THE OUTER CASE REMOVED, LIVE

COMPONENTS BECOME EXPOSED.

To assist in filling and venting, the pump may be operated:

Connect the electrical supply, set switch “C” to “On”, white flash

showing, any remote heating systems controls, time switch

and/or room thermostat to call for heat, see diagram 11.1.

Note. If the clock/timer is fitted into the boiler, refer to the setting

instructions in the Instructions for Use.

Make sure that the automatic air vent is operating correctly, see

diagram 11.2.

Take care not to splash any of the electrical components.

Alternate the position of switch “C” between “On” and “Off”

positions to ensure that water flows through all parts of the boiler

and air is not trapped in the boiler internal bypass.

Pressurise the system until the pressure is 1.5bar (21.5lbf/in

2

).

Check the heating system and boiler for water soundness.

Check the operation of the safety valve by turning the safety

valve knob in the direction of the arrow.

Lower the pressure to the initial cold fill design pressure, refer

to Section 1.6 “Data”. Position the set pointer on the boiler

pressure gauge at this pressure also.

11.3 Preparation for Lighting

Isolate the boiler from the mains electrical supply at the external

isolator.

Test for soundness and purge air from the gas supply. Turn on

the gas service cock, slot in line with the length of the cock.

SIT only - Slacken the two piezo unit bracket screws and

remove the bracket, keyhole slot.

Slacken the burner pressure test point screw and connect a

suitable pressure gauge, see diagram 11.3.

Loading...

Loading...