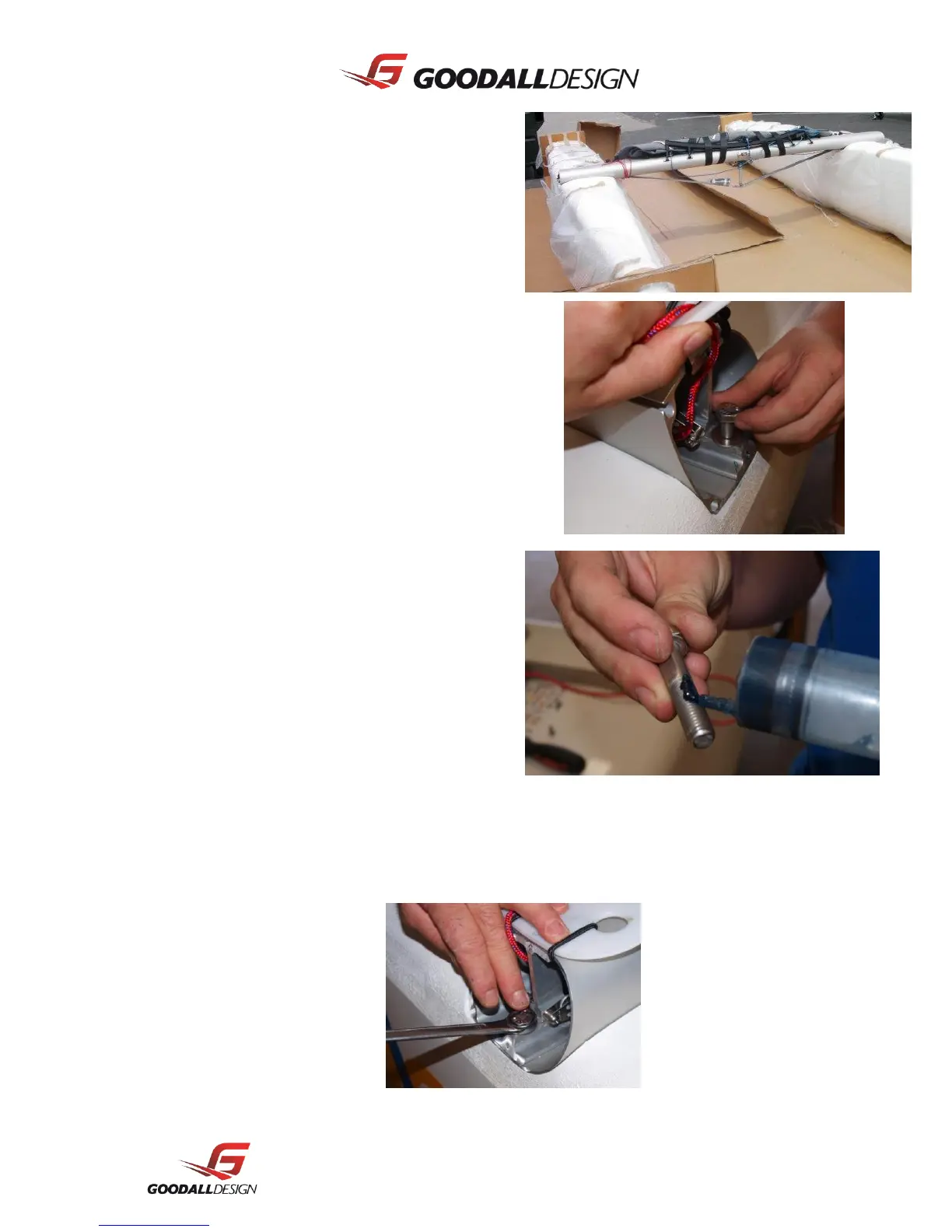

1. Place the 2 cardboard boxes that contain the

hulls parallel on a flat surface approximately

2 meters apart and carefully cut the top open.

The sides of the boxes may be folded down

to provide a clean and protective working

surface. The packing frames inside the box

should keep the hulls upright while you work.

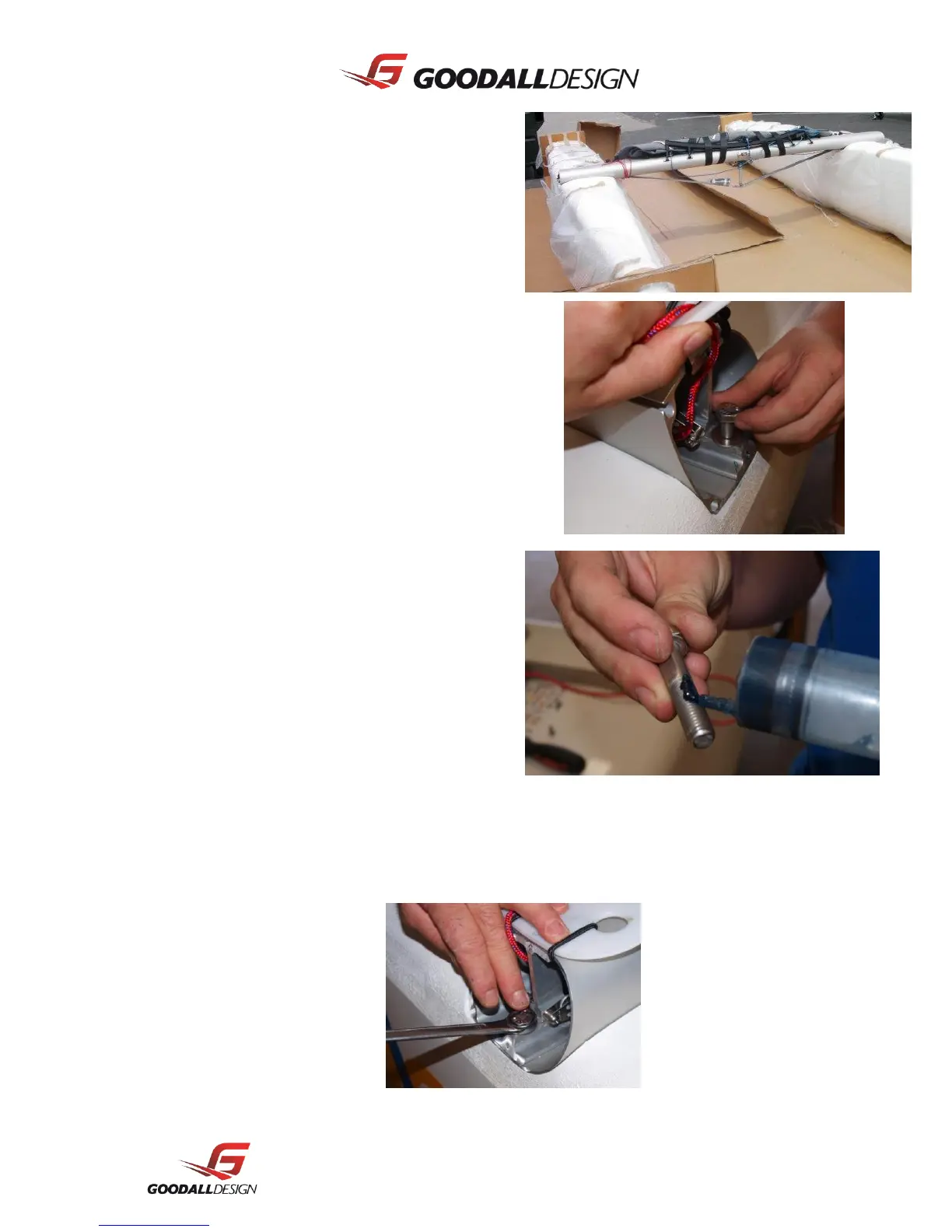

2. The beams will come from the factory pre-

rigged and ready to go onto the boat. The

shorter bolts and smaller washers are for the

outer locations and the longer bolts and

bigger washers for the inner locations. To

access the outer bolt holes you will have to

remove the plastic end caps from the beams

with a Phillips head screwdriver, don’t undo

any of the shock cords on the front beam as

they are already in the correct position.

3. Wipe all dirt and grease from the beam pad

before sitting the beam on. Make sure the

beams are facing the correct way. The rear

beam should have the traveler saddles facing

backwards. Apply grease to the threaded part

of all bolts before inserting them into the hull.

Get all the bolts started before tightening any

of the bolts. We recommend beginning with

the inner front beam bolt. If a particular bolt

is being difficult to fit. Release all the beam

bolts and fit this bolt first.

4. Use a 17 mm hexagonal socket or spanner to tighten the bolts properly. The bolts should be set to

20Nm using a torque wrench. Check the bolts regularly but in never exceed the recommended 20

Nm.

Loading...

Loading...