12

AIR FLOW M EASUREMENT AND A DJUSTMENT

Please review the Duct Work section before proceeding

with the airflow measurements and adjustments in this

section.

Unit blower curves (see Specification Sheets) are based on

external static pressure (ESP per in/W.C.). The duct openings

on the unit are considered internal static pressure. As long as

ESP is maintained, the unit will deliver the proper air up to the

maximum static pressure listed for the CFM required by the

application (i.e. home, building, etc.)

In general, 400 CFM per ton of cooling capacity is a rule of

thumb. Some applications depending on the sensible and

latent capacity requirements may need only 350 CFM or up to

425 CFM per ton. Check condition space load requirements

(from load calculations) and equipment expanded ratings data

to match CFM and capacity.

After unit is set and duct work completed, verify the ESP with a

1-inch inclined manometer with pilot tubes or a Magnahelic

gauge and confirm CFM to blower curves in the Specification

Sheets.

NOTE: Never run CFM below 350 CFM per ton, evaporator

freezing or poor unit performance is possible.

AIR F LOW ADJUSTMENTS FOR INDOOR B LOWER MOTOR

X-13 Motor

Adjust the CFM by changing the 24V low voltage lead at the

speed terminal block on the motor. (T1-Low Speed, T2 and

T3-Medium Speed, T4 and T5-High Speed).

NOTE: Factory set T1 (G, fan), T2 (cool/Hi cool), T3 (W2 electric

heat), T4 and T5 reserved for high static (cool/Hi cool) and

W2. GPH1548M41 and GPH1560M41 low cool Y1 will run at G

speed.

ECM Motor

The ECM control board is factory set with the dip switch #4 in

the “ON” position for single stage units and to the "OFF"

position for the 2 stage units. All other dip switches are factory

set in the “OFF” position. For most applications, the settings

are to be changed according to the electric heat size.

The ECM motor provides many features not available on the

traditional PSC motor. These features include:

• Improved Efficiency

• Constant CFM

• Soft Start and Stop

• Improved Humidity Control

ECM Motor Speed Adjustment

Each ECM blower motor has been preprogrammed for

operation at 4 distinct air flow levels when operating in Cooling/

Heat Pump mode or Electric Heat mode. These 4 distinct

levels may also be adjusted slightly lower or higher if desired.

The adjustment between levels and the trim adjustments are

made by changing the dip switch(s) either to an "OFF" or "ON"

position.

See Appendix for Blower Performance Data tables.

APH DIP SWITCH FUNCTIONS

The ECM motor has an electronic control that contains eight

(8) 2-position dip switches. The function of these dip switches

is shown in Table 1.

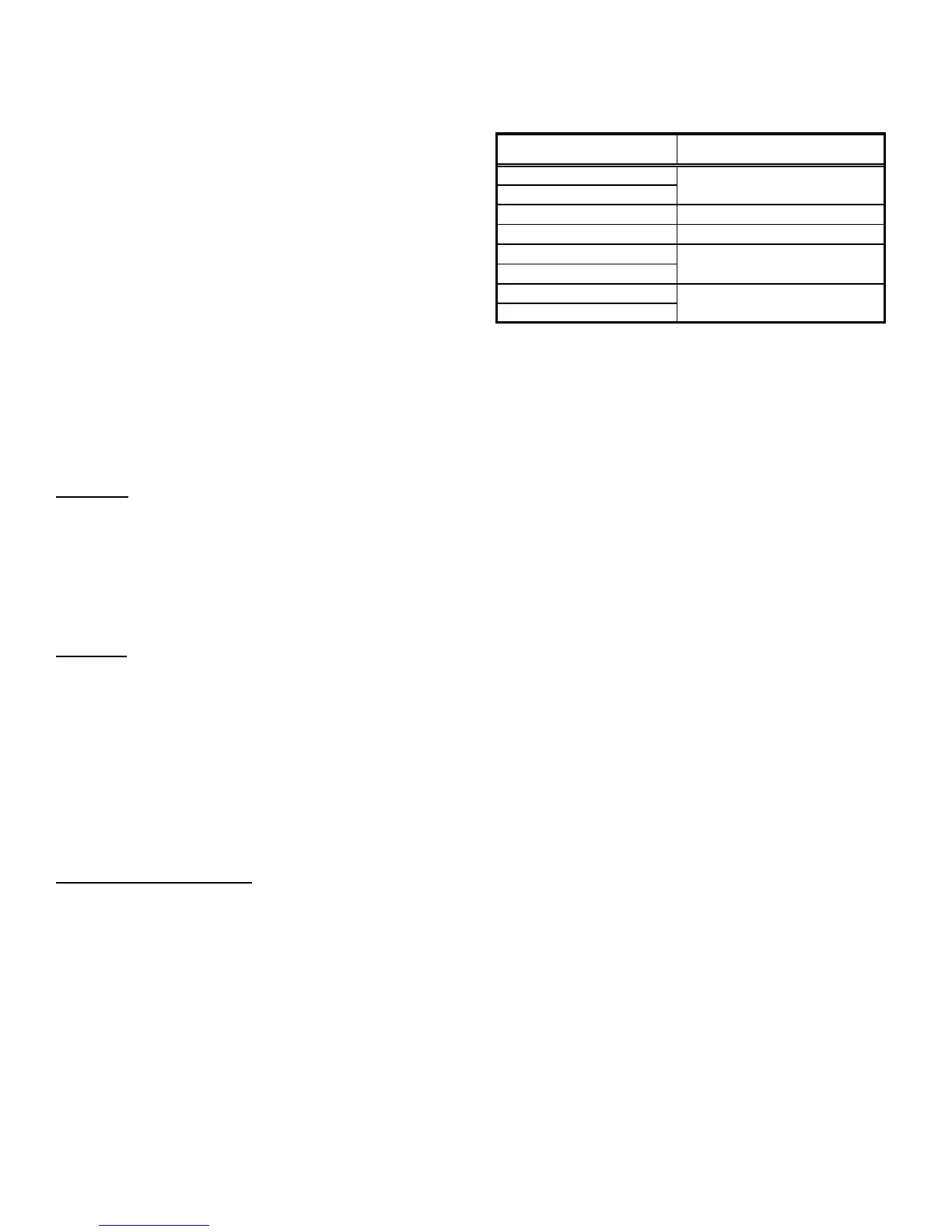

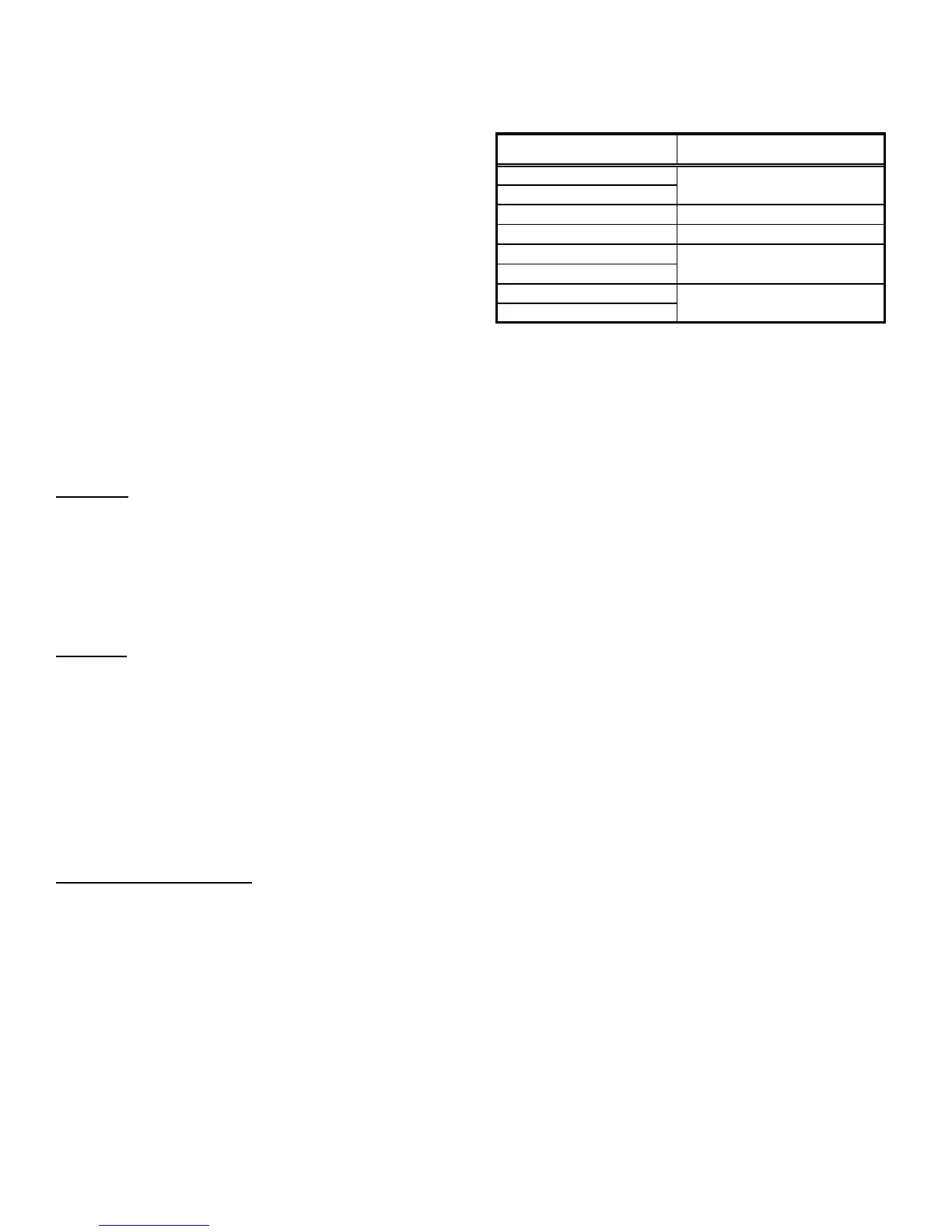

DIP SWITCH NUMBER FUNCTION

1

2

3N/A

4 Indoor Thermostat

5

6

7

8

Cooling & Heat Pump CFM

CFM Trim Adjust

Electric Heat

Table 1

For APH1524-43 models, dip switch 4 must be set to ON. Dip

switch 4 must be set to OFF for two-stage compressor models

APH1549-60. Dip switch 4 ON energizes Y1 signal to the

ECM motor anytime Y/Y2 is energized. The indoor motor will

not operate properly if switch is not set correctly for the model.

APH CFM DELIVERY AND ADJUSTMENTS

See Appendix for CFM Output, Adjustments and DIP switch

settings.

APH THERMOSTAT “FAN ONLY” MODE

During Fan Only Operations, the CFM output is 50% of the high

stage cooling setting.

APH HUMIDITY CONTROL

When using a Humidistat (normally closed), cut jumper PJ6 on the

control board. The Humidistat will only affect both low stage and

high stage cooling air flow by adjusting the Air flow to 85%.

APH TWO-STAGE HEATING

When using staged electric heat, cut jumper PJ4 on the control

board.

APH THERMOSTAT W IRING

Use thermostat wiring diagrams provided with the thermostat

when making these connections.

See Appendix for Blower Performance tables.

SUPERHEAT CAN BE DETERMINED AS FOLLOWS:

1. Read suction pressure. Determine Saturated Suction

Temperature from tables or pressure gauge saturated

temperature scale (R-410A).

2. Read suction line temperature.

3. Use the following formula:

SUPERHEAT = SUCTION LINE TEMP - SAT. SUCTION TEMP

Loading...

Loading...