13

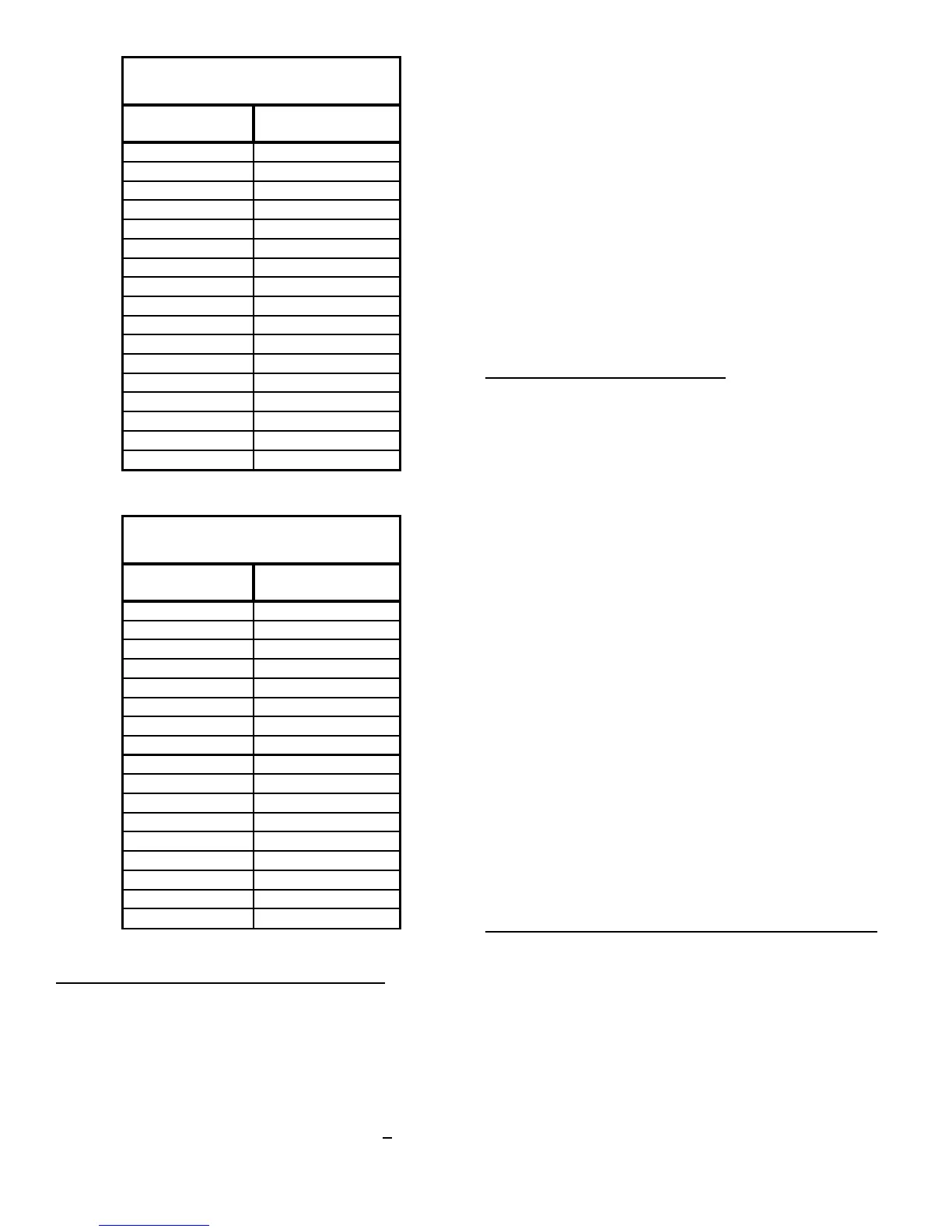

Suction

Pressure

Saturated Suction

Tem

erature °F

PSIG R-410A

50 1

52 3

54 4

56 6

58 7

60 8

62 10

64 11

66 13

68 14

70 15

72 16

71 17

76 19

78 20

80 21

SATURATED SUCTION PRESSURE

TEMPERATURE CHART

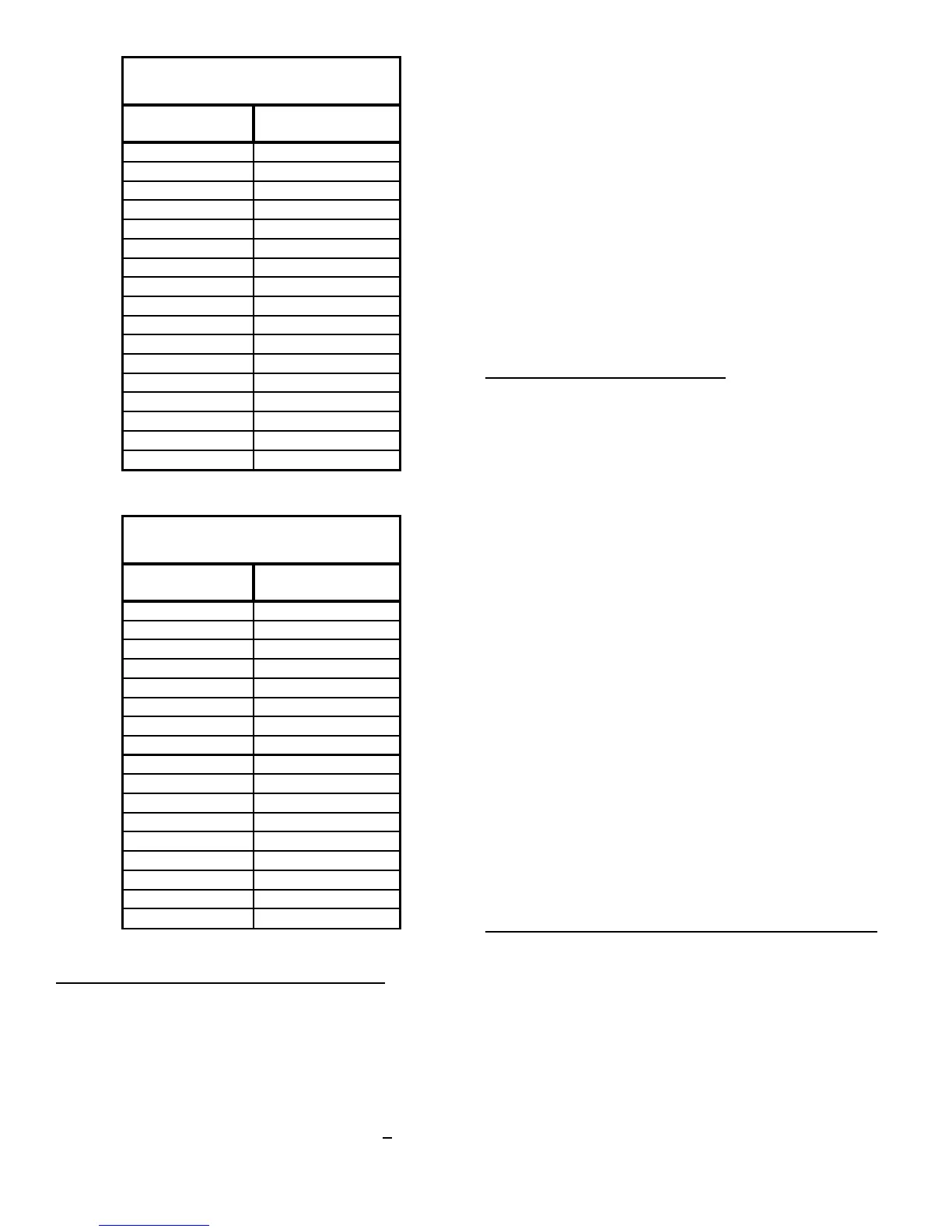

SUBCOOLING = SAT. LIQUID TEMP. - LIQUID LINE TEMP.

Liquid

Pressure

Saturated Liquid

Tem

erature °F

PSIG R-410A

200 70

210 73

220 76

225 78

235 80

245 83

255 85

265 88

275 90

285 92

295 95

305 97

325 101

355 108

375 112

405 118

SATURATED LIQUID PRESSURE

TEMPERATURE CHART

EXPANSION VALVE (TXV) SYSTEM

Single Speed Application (*PH1524/43 and GPC15)

1. Purge gauge lines. Connect service gauge manifold to

access fittings. Run system at least 10 minutes to allow

pressure to stabilize.

2. Temporarily install thermometer on liquid (small) line near

liquid line access fitting with adequate contact and insulate

for best possible reading.

3. Check subcooling and superheat. Systems with TXV

application should have a subcooling of 10 + 2°F and

superheat of 15 to 18ºF.

a. If subcooling and superheat are low, adjust TXV to 15

- 18ºF then check subcooling.

b. If subcooling is low and superheat is high, add charge

to raise subcooling to 10 ± 2ºF then check superheat.

c. If subcooling and superheat are high, adjust TXV valve

to 15 - 18ºF then check subcooling.

d. If subcooling is high and superheat is low, adjust TXV

valve to 15 to 18ºF superheat and remove charge to

lower the subcooling to 10 ± 2ºF.

The TXV should NOT be adjusted at light load conditions 55º

to 60ºF, under such conditions only the subcooling can be

evaluated. This is because suction pressure is dependent

on indoor air flow, and wet bulb temperature.

NOTE: Do NOT adjust charge based on suction pressure

unless there is a gross undercharge.

4. Disconnect manifold set. Installation is complete.

Two Speed Application (*PH1549/60)

Run the unit on low stage cooling for 10 minutes until

refrigerant pressures stabilize. Follow the guidelines and

methods below to check unit operation and ensure that the

refrigerant charge is within limits. Charge the unit on low

stage.

1. Purge gauge lines. Connect service gauge manifold to

access fittings. Run system at least 10 minutes to allow

pressure to stabilize.

2. Temporarily install thermometer on liquid (small) line near

liquid line access fitting with adequate contact and insulate

for best possible reading.

3. Check subcooling and superheat. Two stage systems

running on low stage with TXV application should have a

subcooling of 5 to 7 ºF and superheat of 15 to 18ºF.

a. If subcooling and superheat are low, adjust TXV to 15

to 18ºF superheat, then check subcooling.

NOTE: To adjust superheat, turn the valve stem

clockwise to increase and counter clockwise to

decrease.

b. If subcooling is low and superheat is high, add charge

to raise subcooling to 5 to 7 ºF then check superheat.

c. If subcooling and superheat are high, adjust TXV valve

to 15 to 18ºF superheat, then check subcooling.

d. If subcooling is high and superheat is low, adjust TXV

valve to 15 to 18ºF superheat and remove charge to

lower the subcooling to 5 to 7 ºF.

NOTE: Do NOT adjust the charge based on suction

pressure unless there is a gross undercharge.

4. Disconnect manifold set, installation is complete.

Refrigerant Charge Check (Units with Fixed Orifice Devices)

After completing airflow measurements and adjustments the

unit’s refrigerant charge must be checked. The unit comes

factory charged, but this charge is based on 325 CFM per ton

and minimum ESP per ARI test conditions (generally between

.15 -.25 ESP). When air quantity or ESP is different than above,

the refrigerant charge must be adjusted to the proper amount.

All package units with fixed orifice devices are charged using

the super heat method at the compressor suction line.

For charging in the warmer months, 8 ± 3ºF superheat at the

compressor is required at conditions 95ºF outdoor ambient

(dry bulb temperature), 80ºF dry bulb / 67ºF wet bulb indoor

ambient, approximately 50% humidity. This superheat varies

when conditions vary from the conditions described.

Loading...

Loading...