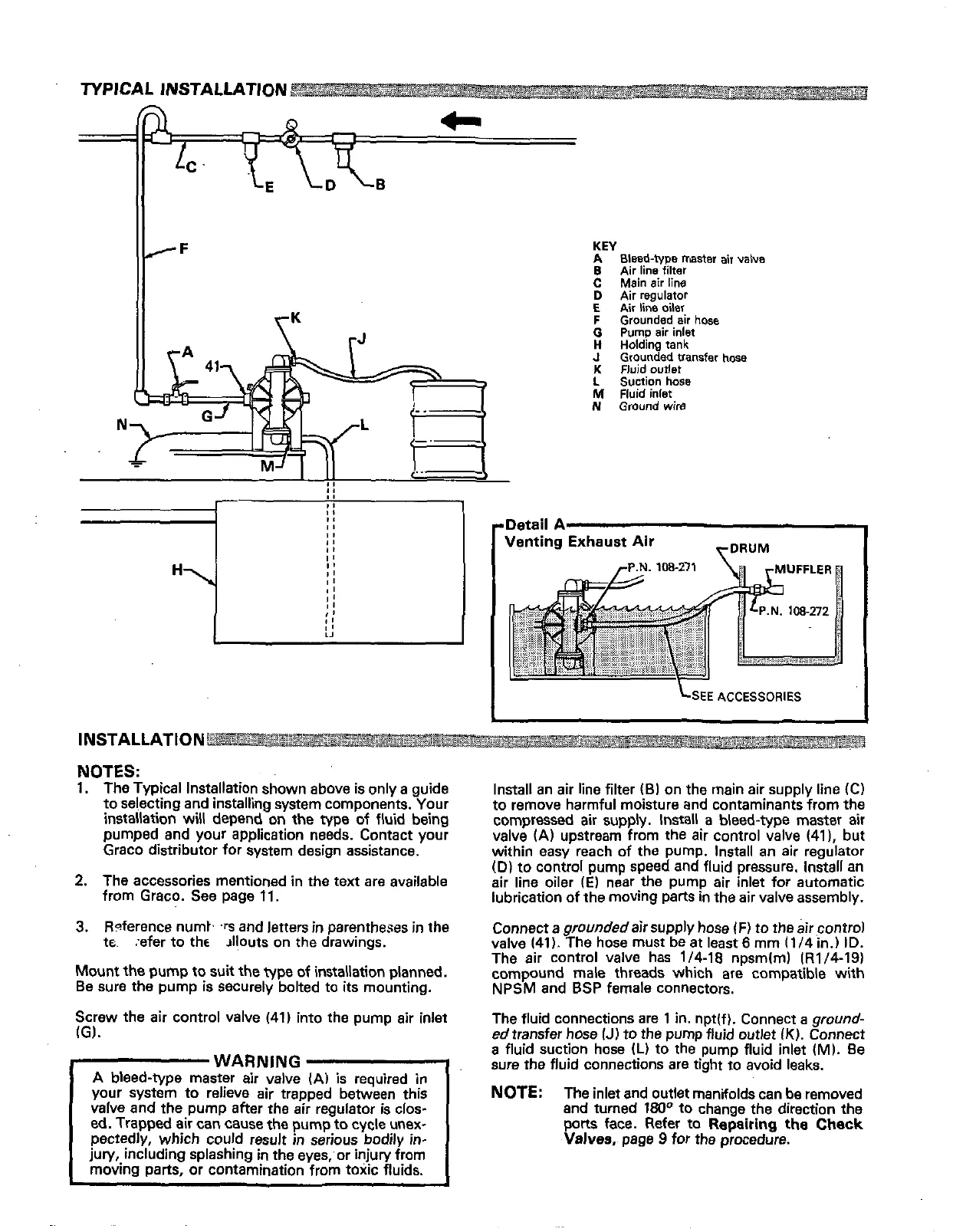

TYPICAL INSTALLATION

KEY

A

Bleed-type master air valve

B

Air line filter

C

Main

air

line

D

Air regulator

E

Air line oiler

F

Grounded air

hose

0

Pump

air

inlet

J

Grounded transfer

hose

H

Holding

tank

K

Fluid ourlet

L

Suction hose

N

Ground

wire

M

fluid inlet

Ir

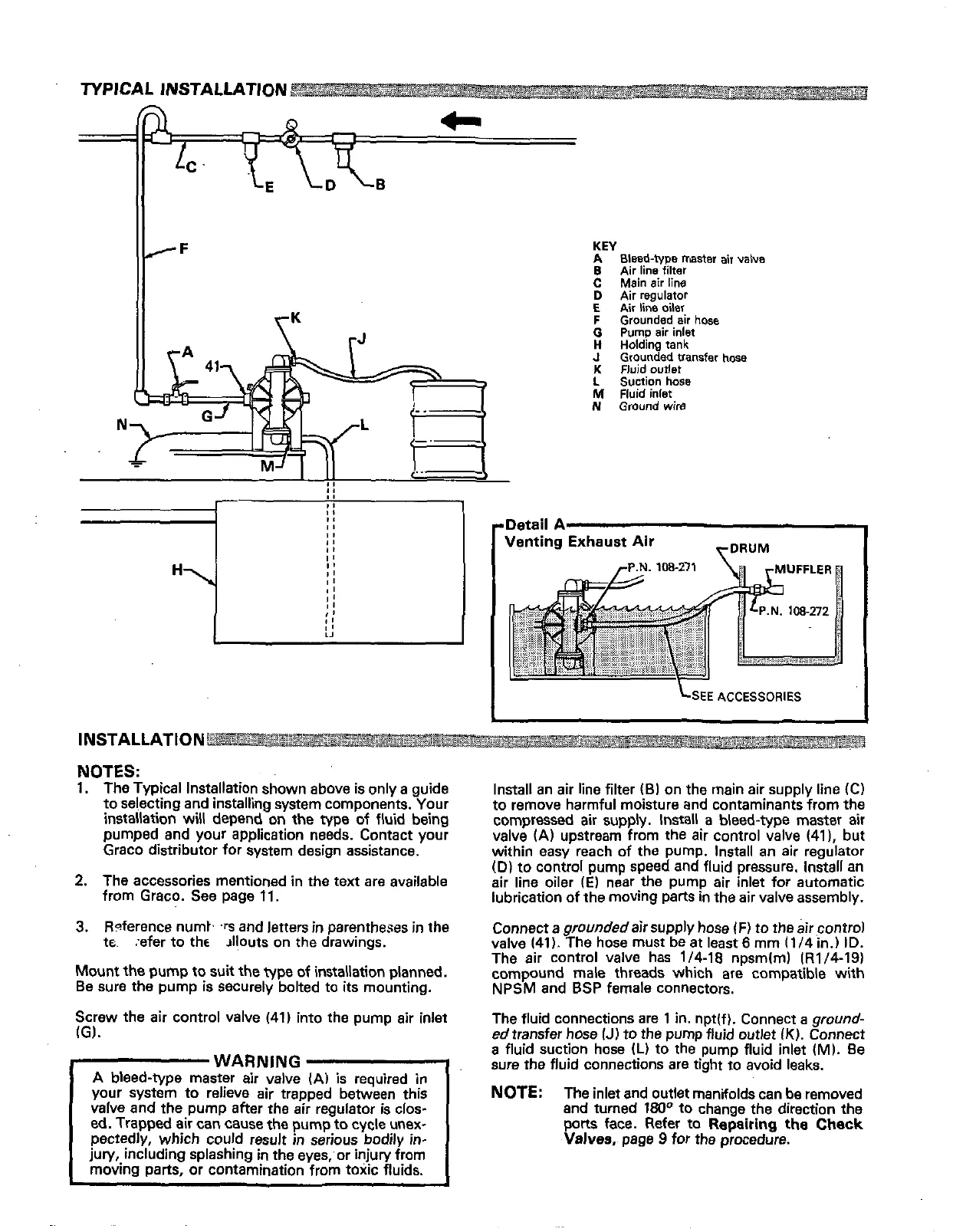

Detail

A

Venting Exhaust

Air

I

LSEE

ACCESSORIES

INSTALLATION

NOTES:

1.

The Typical Installation shown above is only a guide

to selecting and installing system components. Your

installation

will

depend on the type of fluid being

pumped and your application needs. Contact your

Graco distributor for system design assistance.

2.

The accessories mentioned in the text are available

from Graco.

See

page 11.

3.

Roference numt.

'rs

and

letters

in

parentheses

in

the

tc. :efer to

the

Jllouts on the drawings.

Mount

the

pump

to suit the

type

of installation planned.

Be sure the pump is securely bolted to its mounting.

Screw the air control valve (41) into the pump air inlet

IG).

A

bleed-type master air valve

(A)

is

required in

WARNING

valve and the pump after the

air

regulator is clos-

your system to relieve air trapped between this

ed.

Trapped air can cause the pump

to

cycle unex-

pectedly, which could result

in

serious bodily

in-

jury, including splashing

in

the eyes;or injury from

moving parts, or contamination from toxic fluids.

to remove harmful moisture and contaminants from the

Install

an

air line filter

(BI

on the main air supply line

(C)

valve

(A)

upstream from the air control valve (411, but

compressed air supply. Install

a

bleed-type master air

within easy reach of the pump. Install

an

air regulator

(D)

to control pump speed and fluid pressure. Install an

air line oiler

(E)

near the pump air inlet for automatic

lubrication of the moving parts

in

the air valve assembly.

valve 141).

The hose must be at least

6

mm

(114

in.)

ID.

Connect a

grounded

air supply

hose

IF)

to the air control

The air control valve has 1/4-18 npsm(m) (R1/4-19)

compound male threads which are compatible with

NPSM

and

BSP

female connectors.

The fluid connections are 1

in.

npt(f). Connect a ground-

ed transfer

hose

IJ)

to

the

pump

fluid outlet

(K).

Connect

a fluid suction hose

(L)

to the pump fluid inlet

(MI.

Be

sure the fluid connections are tight to avoid leaks.

NOTE:

The inlet and outlet manifolds can be removed

and turned

180°

to

change the direction the

pons

face. Refer to Repairing

the

Check

Valves,

page

9

for the procedure.

Loading...

Loading...