6 309662

Troubleshooting (Contd)

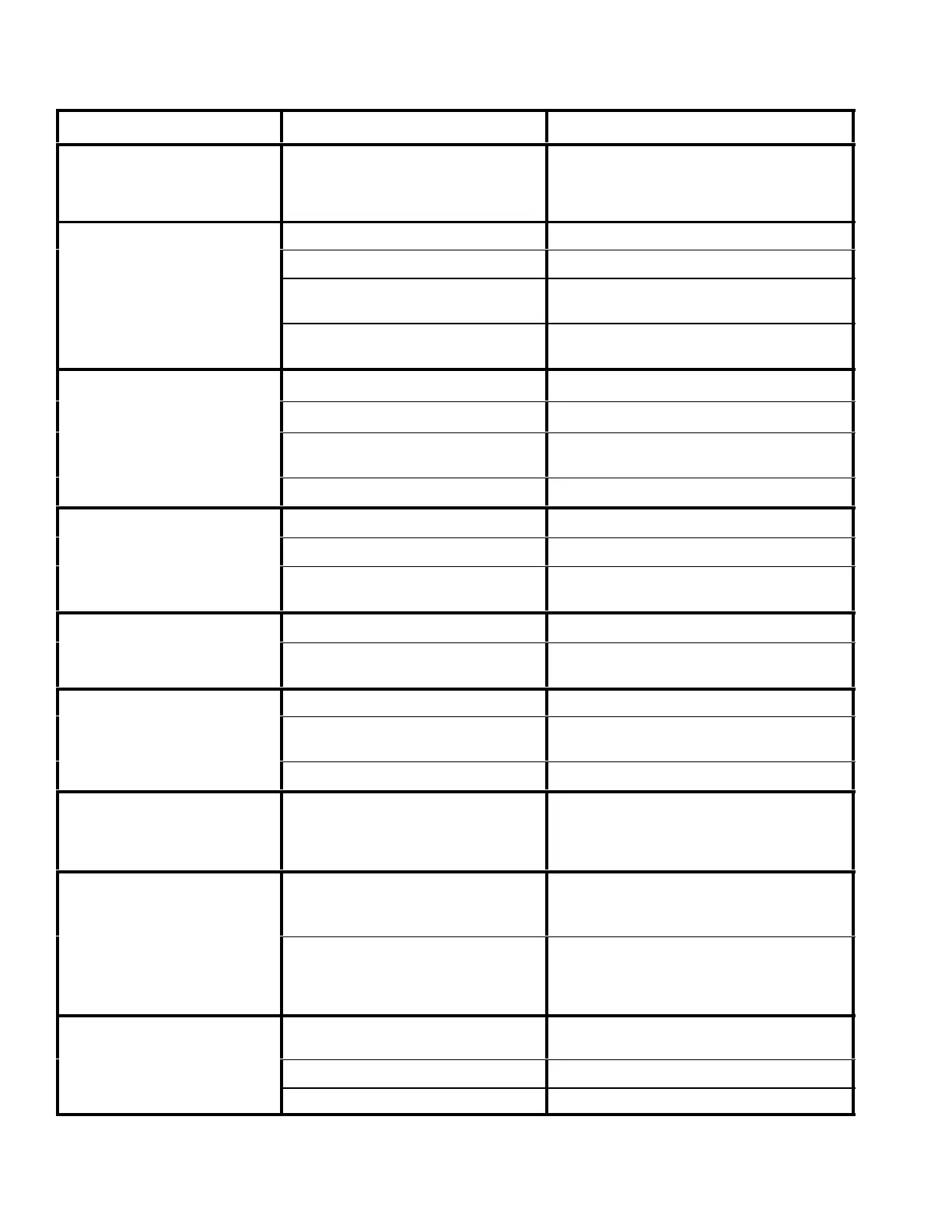

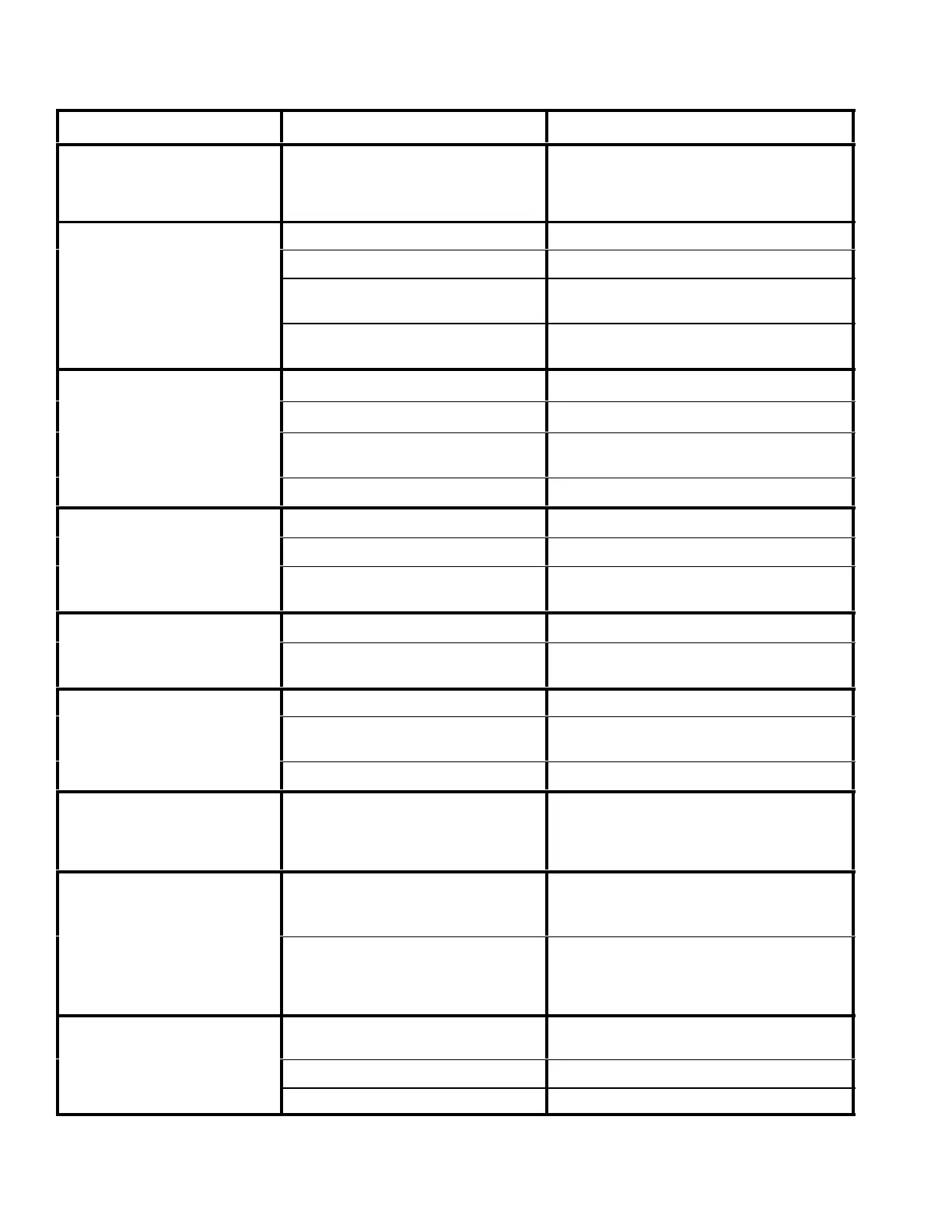

PROBLEM CAUSE SOLUTION

Loss of air control or volume

at gun

Air passages clogged with material After releasing gun trigger, make sure

system is fully depressurized before trig-

gering gun again. This helps prevent

material backing into gun passages.

Displacement pump output

p

Piston ball (220) not seating Clean piston area. See page 8.

ow on upstro

e

Piston packings worn or damaged Replace packings. See page 8.

Siphon hose coupling gasket (1e)

worn or missing.

Replace or install gasket

Pump cylinder o-ring (205) worn or

missing

Replace o-ring

Displacement pump output

low on downstroke or both

Siphon hose strainer is clogged Clean strainer

ow on

owns

ro

e or

o

strokes

Piston packings worn or damaged Replace packings. See page 8.

Intake valve ball (216) not seating

properly

Clean and service intake valve. See

page 8.

Clutch (9) worn or damaged Replace clutch. See page 14.

Material leaks into wet-cup Loose wet-cup (202) Tighten wet-cup enough to stop leakage

Throat packings worn or damaged Replace packings. See page 8.

Displacement rod (201) worn or

damaged

Replace displacement rod. See page 8.

Low fluid delivery Siphon hose strainer is clogged. Clean or remove strainer

Engine RPM too low Increase engine speed. See Startup,

procedure in operator manual.

No fluid delivery Flow control not set to PRIME Set flow control to PRIME

Compressor is not on and/or air

hoses are not properly connected

Check and correct

Gun is not fully triggered Squeeze trigger firmly and completely.

Spitting from gun Material supply is low or empty Refill and prime pump. See Startup pro-

cedure in operator manual. Check materi-

al supply often to prevent running pump

dry.

Heavy or poorly atomized

material when gun is first trig-

gered

Fluid pressure was not allowed to

fully self relieve after releasing gun

trigger

Wait a little longer between releasing gun

trigger and pulling it again

Gun was not fully triggered immedi-

ately when squeezed, causing gun

air passages to clog with material.

Always squeeze trigger fully to prevent

just air from turning on, which starts pump

and pressurizes hoses. Disassemble and

clean gun.

Material from gun is not atom-

ized, or has insufficient

Gun air control valve is turned fully in Turn air control valve out for desired

atomization.

atom

zat

on

Insufficient compressor air Increase air supply or compressor size

Gun nozzle too small for application Increase nozzle size

Loading...

Loading...