Spraying

2 313895A

Spraying

The spray pattern can be adjusted by changes to:

• Nozzle size

• Fluid and/or air flow

• Air needle position

• FineFinish disk size* (see next page)

The standard applicator adjustment

is to adjust the air

needle slightly behind the fluid nozzle. Fully open the air

valve (3), while adjusting the needle valve (5) for the

minimum air flow necessary for a good pattern.

NOTE: Installing needle (20) too far forward can force

air back into fluid hose, stopping material flow.

Air bleeds from the applicator nozzle

whenever the

applicator air valve (3) is open. Close the valve to stop

the air if desired. Otherwise, the air valve can stay open

during priming.

Adjusting the spray pattern

requires testing to balance

the fluid flow and the air to the applicator, and requires

the correct nozzle size.

Spray Techniques

1. Test the spray pattern on cardboard. Hold the appli-

cator 18-30 in. (455-760 mm) from the surface. Use

this spraying distance for most applications.

2. Adjust fluid flow until material flow is adequate.

3. Adjust the applicator air flow valve (5) to achieve a

uniform round spray pattern.

4. Consider the size of aggregate in the material and

the coarseness of the spray pattern. Larger nozzles

allow heavier patterns.

5. Overlap each stroke 50%. A circular overlapping

pattern may give the best results, and is obtained by

grasping the flexhead (2) and swinging the head

around as the hose flexes.

When spraying small confined areas

use the valve and

knob to make fine adjustments without adjusting the

pump.

Material Flow Adjustments

For a lighter spray pattern, adjust the air needle (20)

closer to the fluid nozzle and/or reduce the fluid flow.

For a heavier spray pattern, adjust the air needle (20)

farther back from the fluid tip and/or increase the fluid

flow.

NOTE: Withdrawing needle (20) too far can force air

back into fluid hose, stopping material flow.

Air Flow Valve Adjustment

To decrease air flow, turn valve knob (5) clockwise.

To increase air flow, turn valve knob (5) counterclock-

wise.

Check material and thin as needed to maintain the

proper consistency. The material may thicken as it sits

and could slow down application or affect the spray pat-

tern.

Flush and dry applicator thoroughly at the end of each

use.

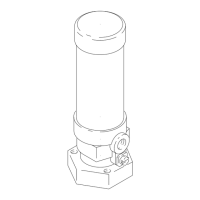

Installing Nozzle Retaining Cap

1. Place nozzle retaining cap over top lip of applicator

housing.

(Optional)

2. Insert screwdriver through hole in tab of nozzle

retaining cap.

3. Push screwdriver head against notch on applicator

tip and pry nozzle retaining cap over lip until it snaps

into place.

ti14355a

Loading...

Loading...