Piston

packings

worn

or

damaged

Intake valve

ball

check

nd

seating

Replace packings.

See

page

26.

Clean and service intake valve.

See

page

26.

properly

EngineRPM twlow

Clutch worn or damaged

Replace Clutch.

See

page

34.

~~

Increase thrdtie

wing.

See

Startup,

Steps

5b and

14,

page

14.

I

I

Partially clogged suction

tube

assembly Remove and clean suction

tube.

During normal

flushing

remove and clean

the

suction

tube

as-

sembly separately

to

prevent further ciMging.

I

1

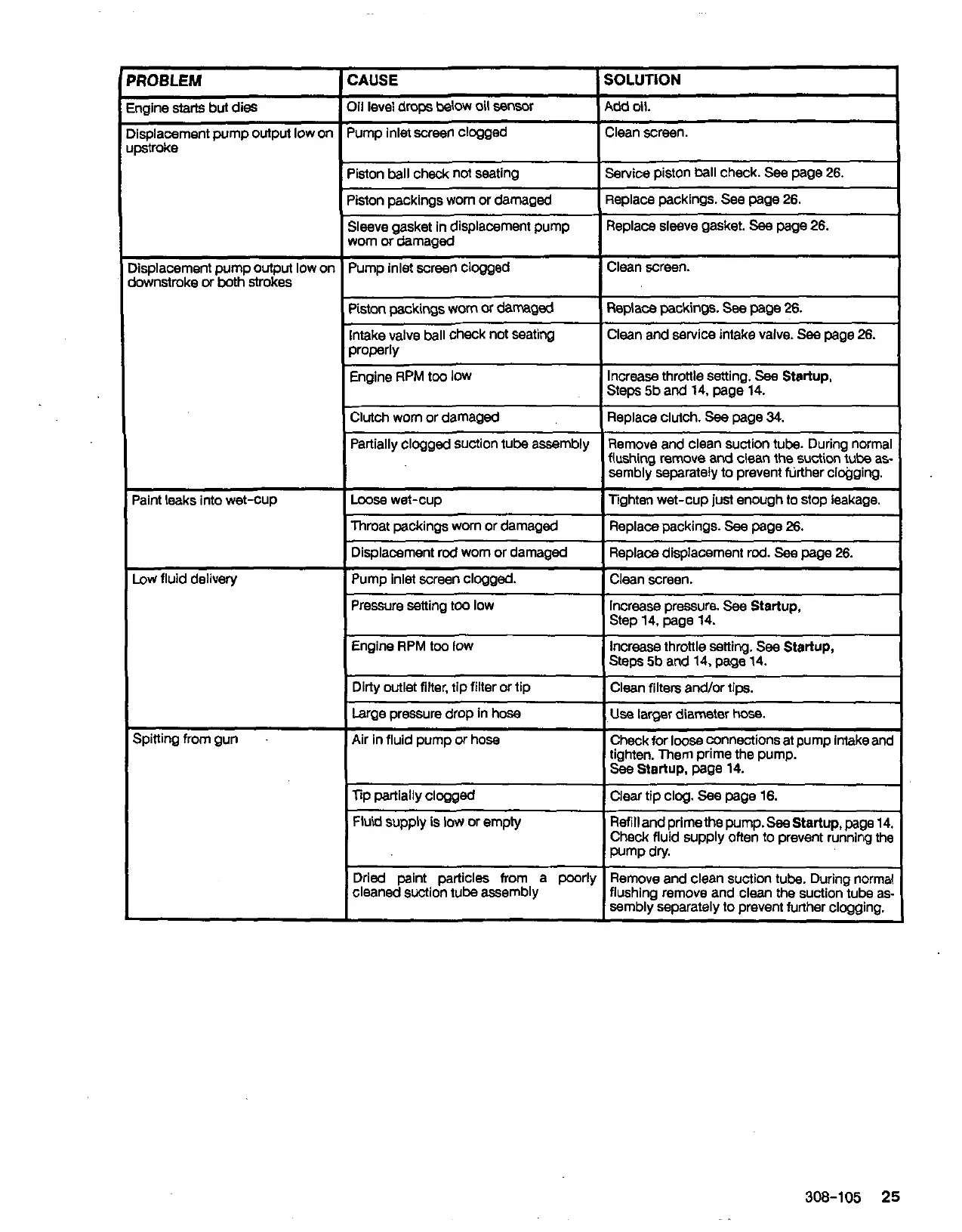

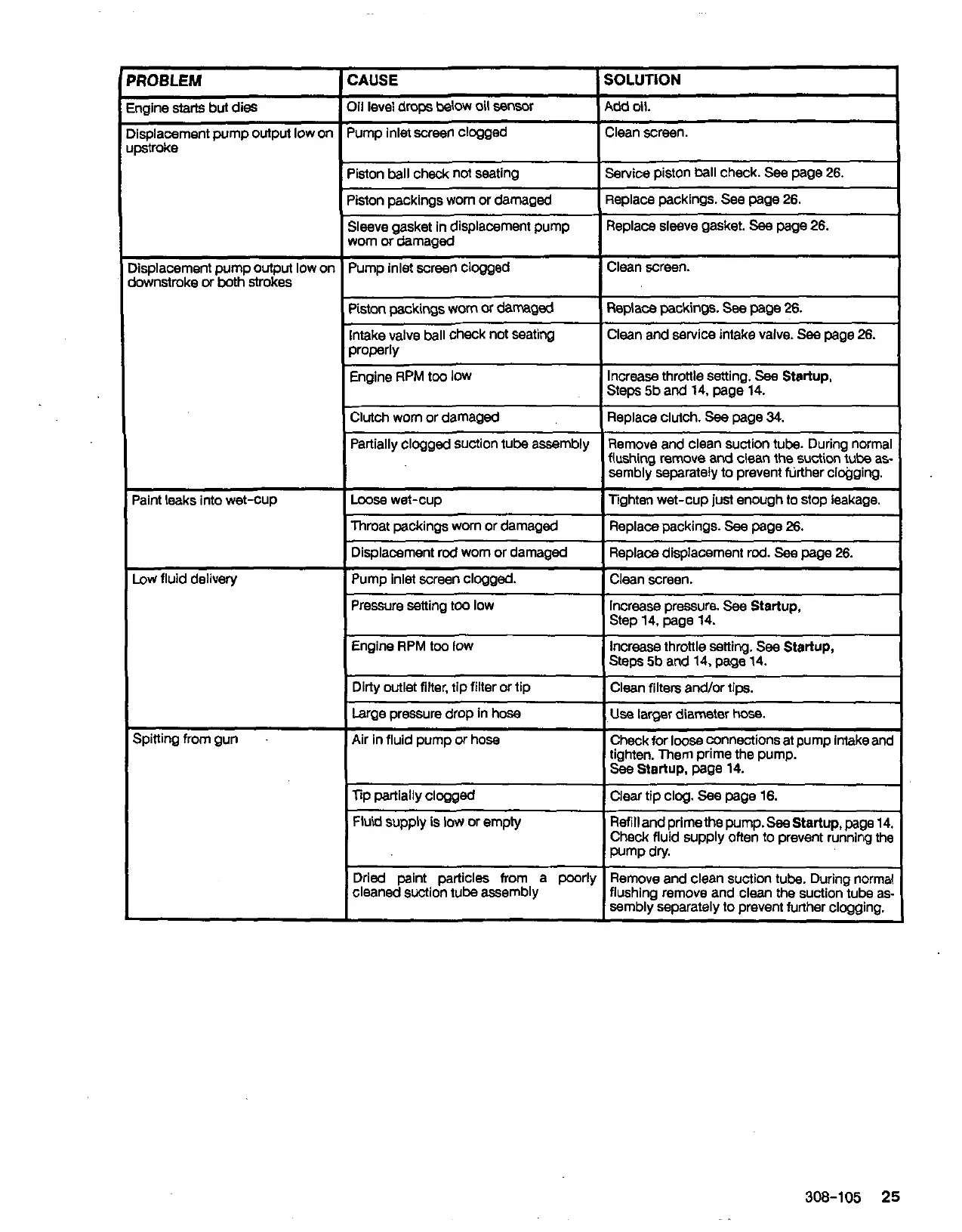

SOLUTION

CAUSE

PROBLEM

Engine

starts

but

dies

upstroke

Clean screen. Pump

Inlet

screen clogged

Displacement pump output low

on

Add

oil.

011

level

drops

below

oil

senw

Piston

ball

check

nd

seating

Replace sleeve gasket.

See

page

26.

Sleeve gasket in displacement pump

Replace paCklngS.

See

page

26.

Piston paCkingS wom or damaged

Service

piston

ball

check. See

page

26.

worn

or

damaged

-

Displacement pump output

low

on

downstroke

or

both

strokes

Pump inlet screen Clogged

Clean scram.

-

I

-

I

-

'aint leaks into wet-cuD

Loose

wet-cup

Replace displacement rod.

See

page

26.

Displacement rod worn or daInaged

Replace packings.

See page

26.

Throat

packings worn or damaged

Tighten Wet-CUP

jUSt

EllOUgh

10

Stop leakage.

IIW

fluid delivery

I

Pump

inlet

screen

clogged.

I

Clean &reen.

I

Pressure setting

too

low

I

Increase pressure.

See

Startup,

step

14,

page

14.

I

Engine RPM

tw

low Increase throttle setting.

See

Startup,

.-

Steps

5b and

14,

page

14.

Dirty

outlet

filter,

tip

filter or tip

I

Clean filterS and/or

tips.

I

Large pressure drop in hose

I

Use

larger diameter

hwe.

Spitting from

gun

Air

in

fluid pump

or

hose Check for

lwse

connections at pump Intake am

tighten. mem prime the pump.

Fluid supply

is

low

or

empty

cleaned

suction

tube

assembly

Dried paint particles from a poorly

Refillandprimethepump.SeeStsrtup,page14,

Check fluid supply ofien

to

prevent running the

fiUShlng remove and clean the suction

tube

as

Remove and clean suciion

tube.

During norma

sembly separately

to

prevent further clwaina.

308-105

25

Loading...

Loading...