TROUBLESHOOTING

GUIDE

WARNING

Pressure

Rellef

Procedure

Toreducetheriskofseriousbodilyinjury,

includingfluid

6.

Open the fluid pressure drain valve and leave it

from moving parts, always

follow

this procedure when

,,

Disconnecl

the

spa*

plug cable.

injection, splashing in the eyes or on

the

skin, or injury

open until you start the sprayer again.

YOU

shut

off

the sprayer, when checking, adjusting

Or

If

you

suspect

the

hose

or

tip

is

co,,,p,ete~

‘leaning

the

system’

and

when

changing

spray

tips‘

clogged

or

that

pressure is

not

fully relieved after fol-

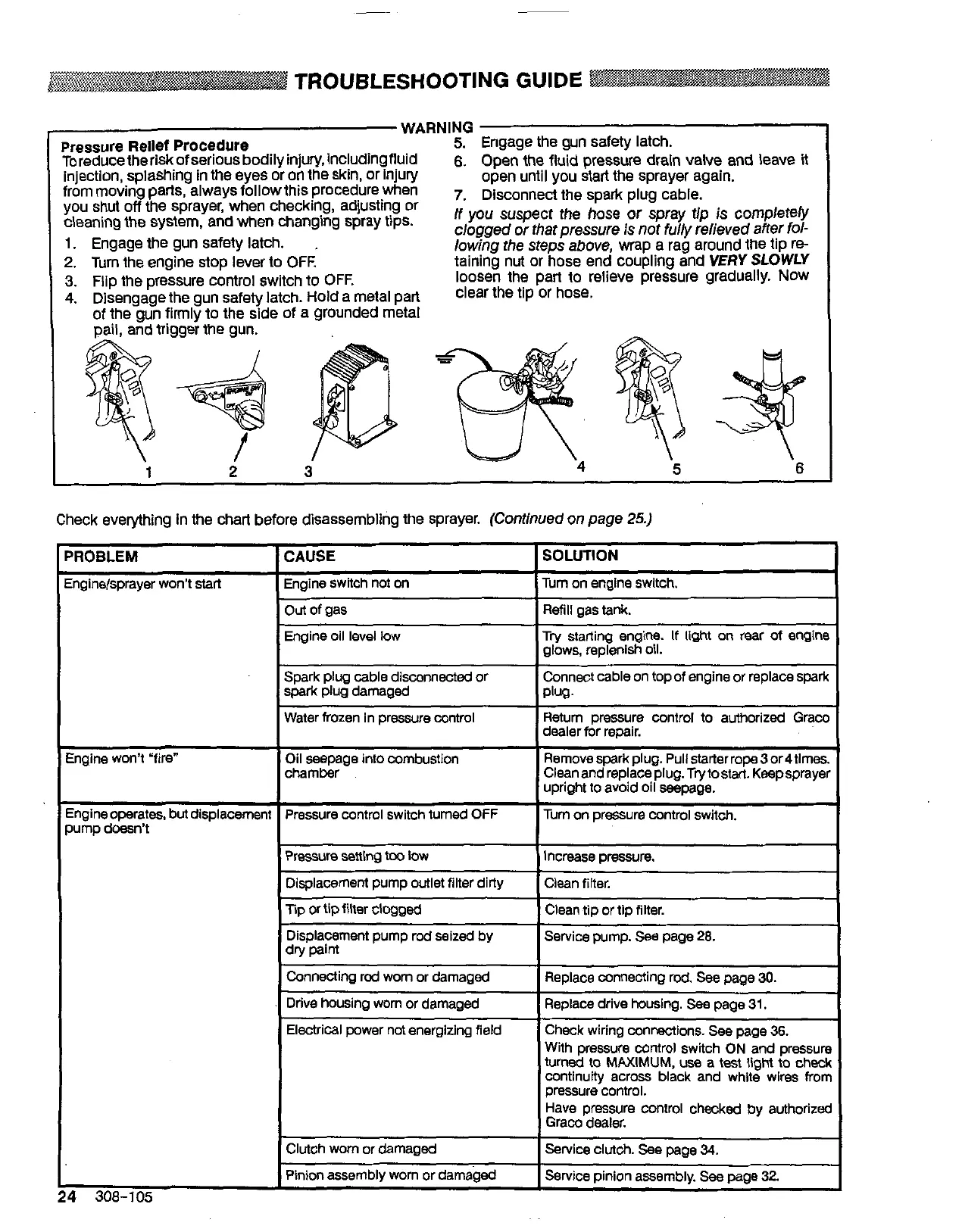

1. Engage the gun safety latch.

2.

Tum the engine stop lever

to

OFF. taining nut or hose end coupling and

VERY

SLOWLY

lowing the

steps

above, wrap

a

rag around the tip re-

3. Flip the pressure control switch to OFF.

4.

Disengage the gun safety latch. Hold a metal part clear the tip

01

hose.

loosen the part

to

relieve pressure gradually.

NOW

5. Engage the gun safety latch.

of the gun firmly to the side of a grounded metal

pail, and lrigger

the

gun.

‘4

5

6

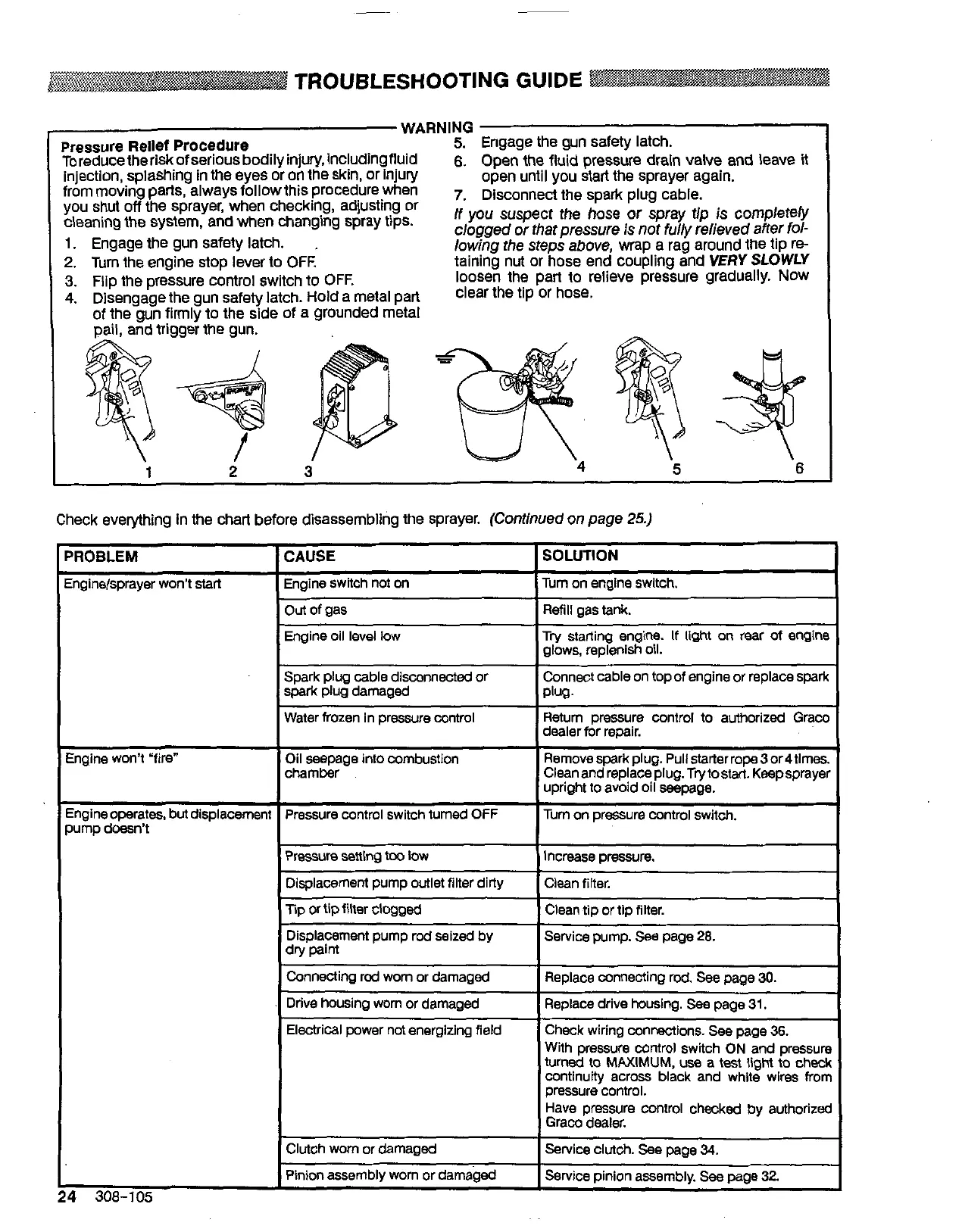

Check everything In the chart before disassembling the sprayer. (Continued

on

page 25.)

PROBLEM

I

CAUSE

I

SOLUTION

I

-

Enginelsprayer won’t

start

Turn

on

engine Switch. Engine switch

not

on

Out

of

gas

TI^

starting engine.

If

li@t

on

rear

of

engine Engine oil

level

low

Refill gas lank.

glows, replenish oil.

I

Spark

plug cable disconnected or Connect cable on top

of

engine

or

replace

spark

spark plug damaged

I

Plug.

I

1-

Water frozen in pressure wntrol

Return

pressure wntrol

lo

authorized Graco

dealer for remir.

Engine won’t “fire”

chamber

Oil seepage into combustion

CleanandreplaCeplug.Trytostart.Keepsprayer

Removespa~~lug.PullstaRerrope3or4times.

upright

to

avoid oil

seepage.

pump

doesn’t

EnginBOpBrates.

but

displacement

Turn

on

pressure wntrol switch.

Pressure control switch turned

OFF

Pressure

setting

too

low

Displacement pump outlet

filter

dirty

Clean tip or tip filter.

Tip

or

tip

filter clogged

Clean filter.

Service pump.

See

page

28.

Displacement pump rod seized by

dry

mint

~~ ~ ~ ~~

Increase pressure.

I

Connecting rod worn or damaged

I

Replace wnnecting rod.

See

page

30.

I

.I

Drive housing worn

or

damaged

I

Replace drive hOUSinQ.

SeS

page

31.

I

Electrical power nd energizing field

With pressure control switch

ON

and pressure

Check wiring wnnections.

See

page

36.

turned

to

MAXIMUM,

use

a test

light

to check

continuity across black and whlte wires

from

pressure control.

1

I

Have pressure control checked

by

authorized

Graco

dealer.

I

Clutch worn or damaged

Pinion assembly worn or damaged

%Nice

Clutch.

See

page

34.

SENICE pinion assembly. See page

32.

!4

308-105

Loading...

Loading...