BEARING HOUSING

&

CON.NECTlNG

ROD

WARNING

dure Warning on page

24

before repairing

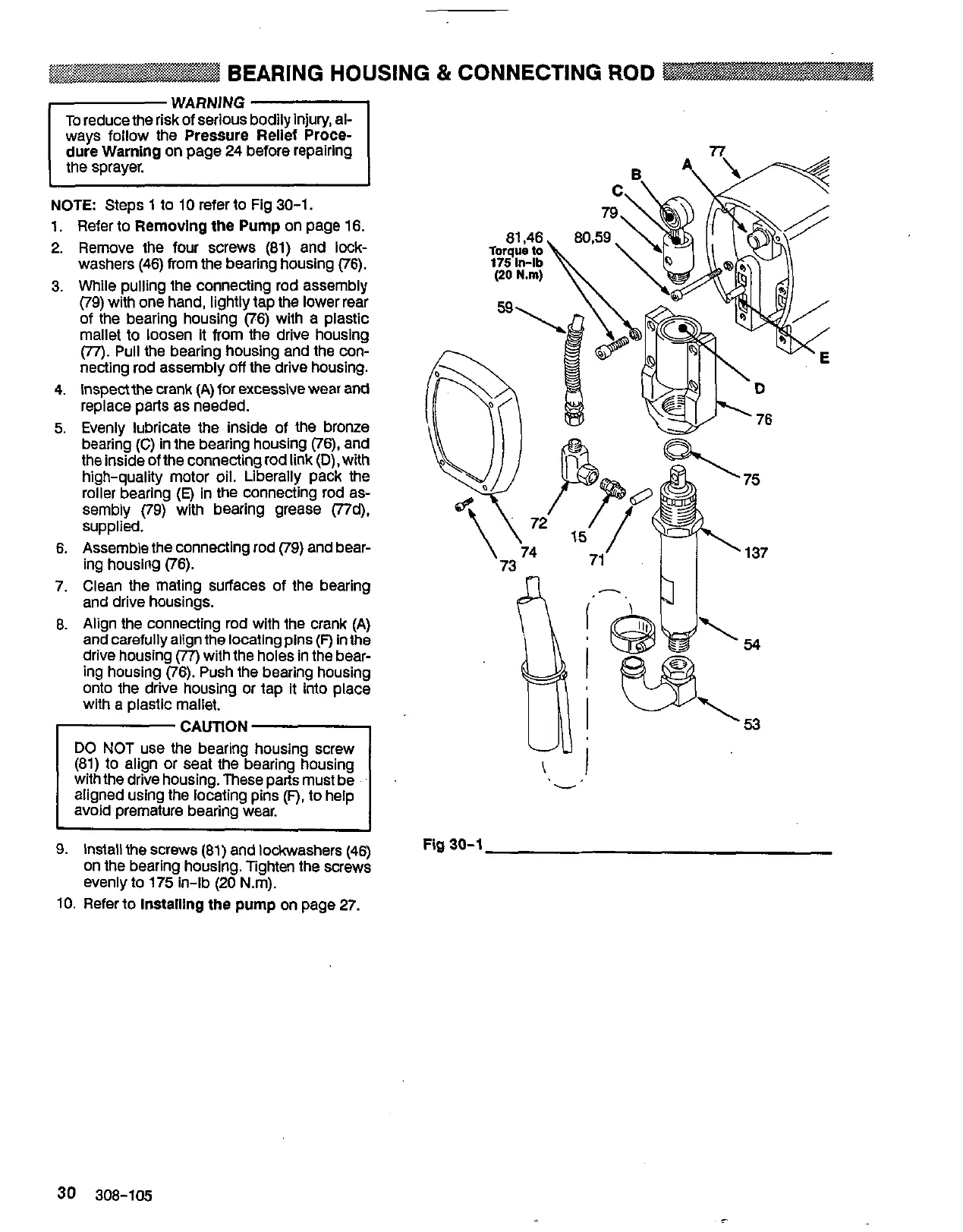

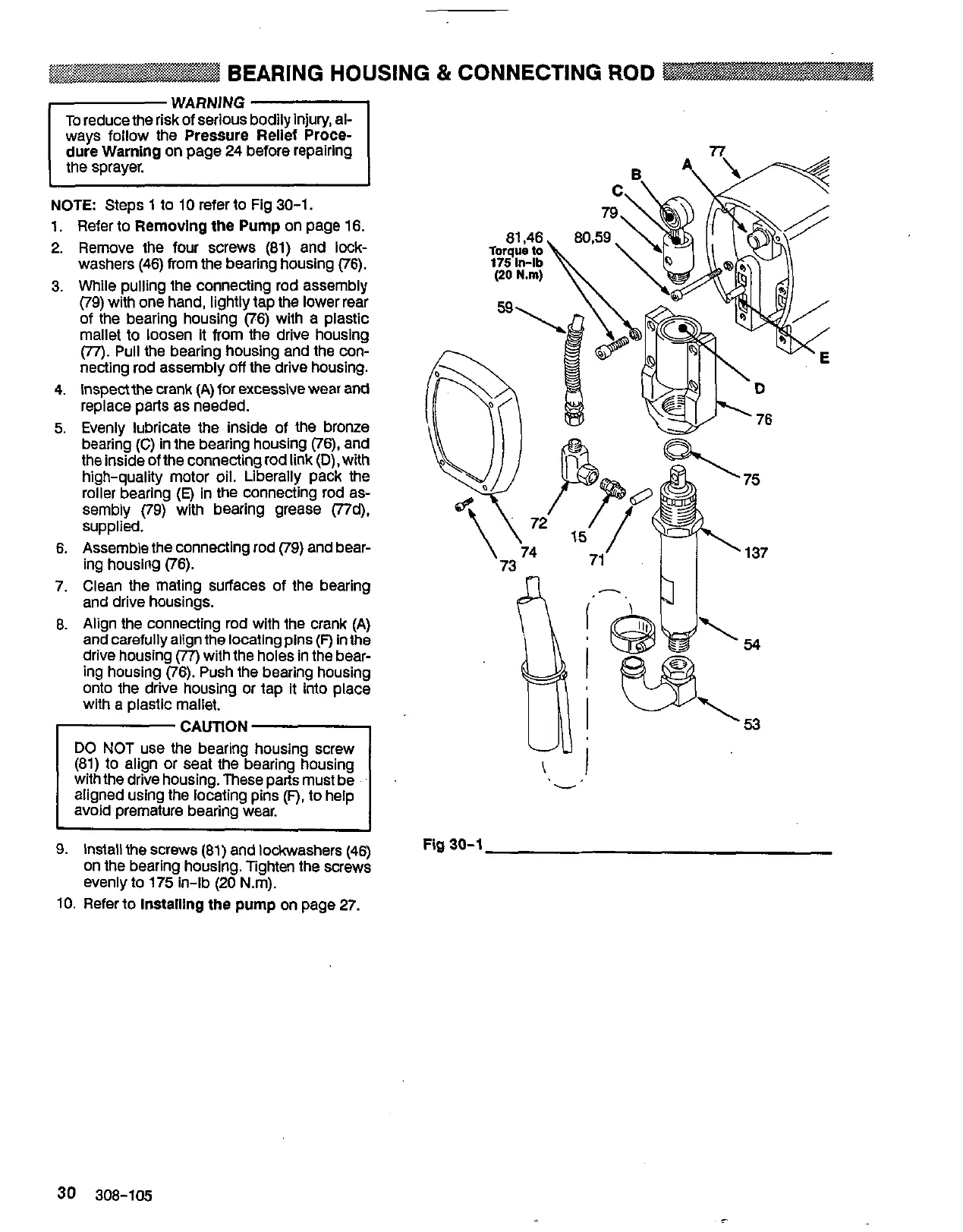

NOTE

Steps

1

to

10

refer to Fig

30-1.

1.

Refer to Removing the Pump on page

16.

2. Remove the four screws

(81)

and lock-

washers

(46)

from the bearing housing

(76).

3.

While pulling the connecting rod assembly

(79)

with one hand, lightly tap the lower rear

of the bearing housing

(76)

with a plastic

mallet to loosen it from the drive housing

necting rod assembly

off

the drive housing.

(77).

Pull

the bearing housing and the con-

4.

Inspect the crank (A) for excessive wear and

replace parts as needed.

5.

Evenly lubricate the inside of the bronze

the inside of the connecting rod link

(D),

with

bearing

(C)

in

the bearing housing

(76),

and

high-quality motor oil. Liberally pack the

roller bearing

(E)

in the connecting rod

as-

sembly

(79)

with bearing grease (Tld),

supplied.

6.

Assemble the connecting rod

(79)

and bear-

ing housing

(76).

7.

Clean the mating surfaces of the bearing

and drive housings.

8.

Align the connecting rod with the crank (A)

and carefully align the locating pins

(F)

in the

drive housing

(77)

with the holes in the bear-

ing housing

(76).

Push the bearing housing

onto the drive housing or tap it into place

with

a

plastic mallet.

.,

u

9.

Install the screws

(81)

and lockwashers

(46)

on the bearing housing. Tighten the screws

evenly to

175

in-lb

(20

N.m).

~~

Fig

30-1

10.

Refer to Installing the pump on page

27.

30

308-105

Loading...

Loading...