PRESSURE

CONTROL CALIBRATION

WARNING

USE EXTREME CAUTION WHEN PERFORMINGTHIS CALIBRATION PROCEDUREto reducethe riskof afluid

injection injury

w other serious bodily injury, which can resuit from component rupture, electric shock, fire, expio-

slon or moving parts.

This procedure sets the sprayer to 2600-3000 psi NEVER attempt to increase the fluid outlet pressure by

1182-210 barl MAXIMUM WORKING

PRESSURE.

oerformina these calibrations

in

anv other wav. NEVER

~~

,

~ ~~~~ ~

~.

I

Perfo~~his procedure whenever the Dressure control PRESSURE. Normal ooeration of the soraver at hioher

'U(CEED

5000

PSI

(210

BAR)

M~IMUM

WORKING

assembly is'removed and reinstalled; or replaced, to

pressures could

res&

in component'rui;ture,

ti&

or

be sure the sprayer

Is

properly calibrated.

explosion.

pressurize and result in component rupture, fire or

ex-

for at least 3000 PSI (210 BAR) MAXIMUM WORKiNG

Improper calibration can cause the sprayer to over- ALWAYS

use

a

new50

foot (15.2

m)

spray hose, rated

the maximum working pressure, resulting

in

poor

under-rated hose could develop a high pressure leak

plosion. It may also prevent the sprayerfrom obtaining PRESSURE, when pelforming this procedure.

A

used,

sprayer performance.

or rupture.

~~ ~ ~ ~~

Service Tools Needed:

NEW

50

foot

(15.2

m).

3000

psi

(210 bar),

flexible nylon airless spray hose,

Pari

No.

223-541

0-5000 psi

(0-350

bar) fluid-filled pressure gauge,

NEW spray tip, size 0.025 to

0.029

Part

No.

102-814

3/8

in.

ignition wrench

or

nut

driver

5

gallon pail

of

water or mineral splrits

Swivel, 156-823

Nipple, 162-453

e

Tee. 104-984

Set Up

1. Follow the Pressure Relief Procedure Warning

on

2.

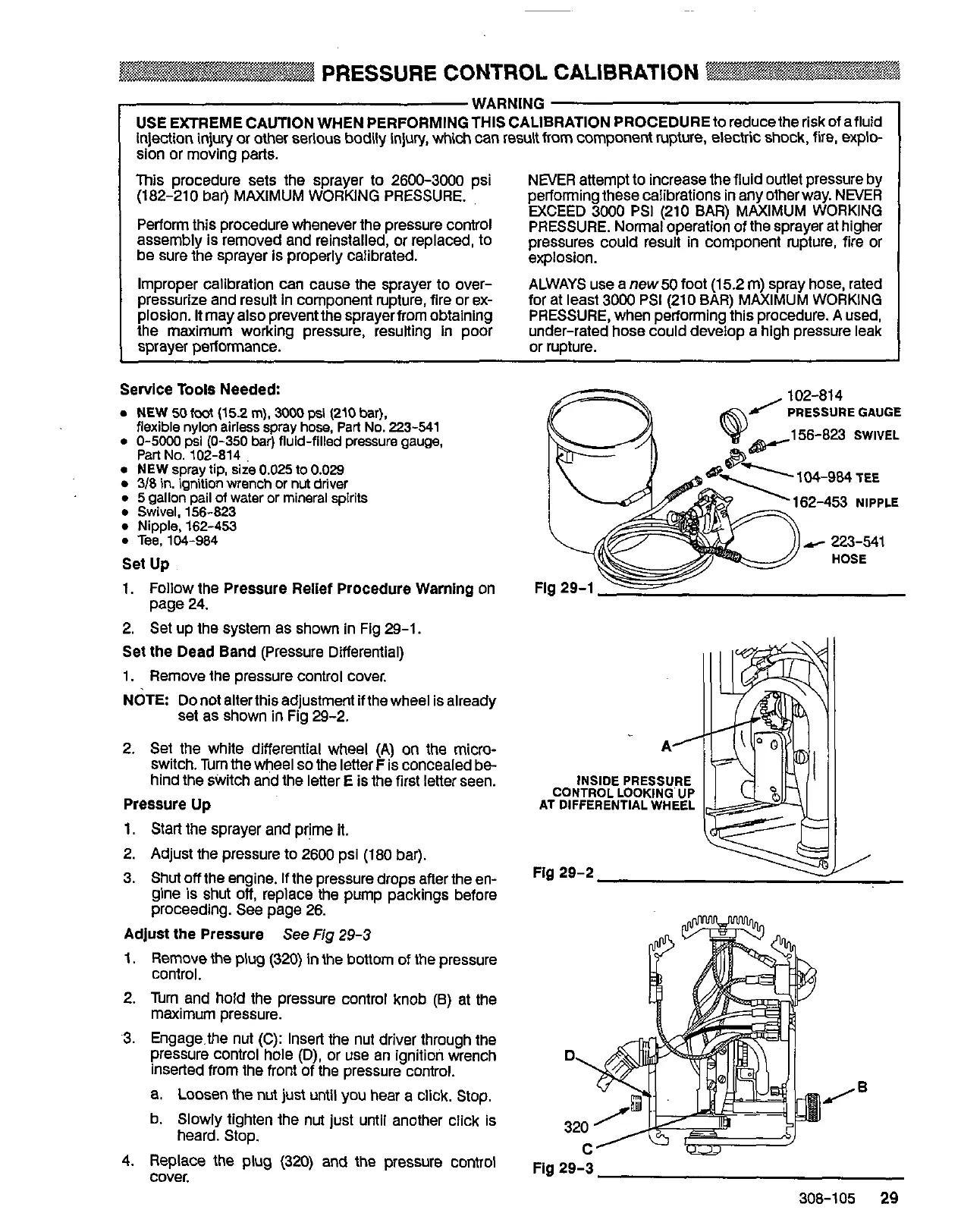

Set up the system as shown in Fig 29-1.

Set the Dead Band (Pressure Differential)

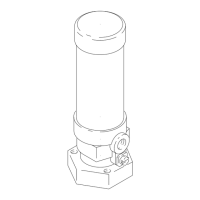

1. Remove the pressure control cover.

NOTE

Do

not alterthis adjustment ifthewheel

is

already

page

24.

set as shown

in

Fig

29-2.

2.

Set the white differential wheel

(A)

on the micro-

switch.

Turn

the wheel

so

the letter

F

is

concealed be

hind the switch and the letter

E is the first letter seen.

Pressure Up

1.

Start the sprayer and

prime

it.

2.

Adjust the pressure to

2600

psi

(180

bar),

3.

Shut

off

the engine.

If

the pressure drops after the en-

gine is shut

on,

replace the pump packings before

proceeding.

See

page

26.

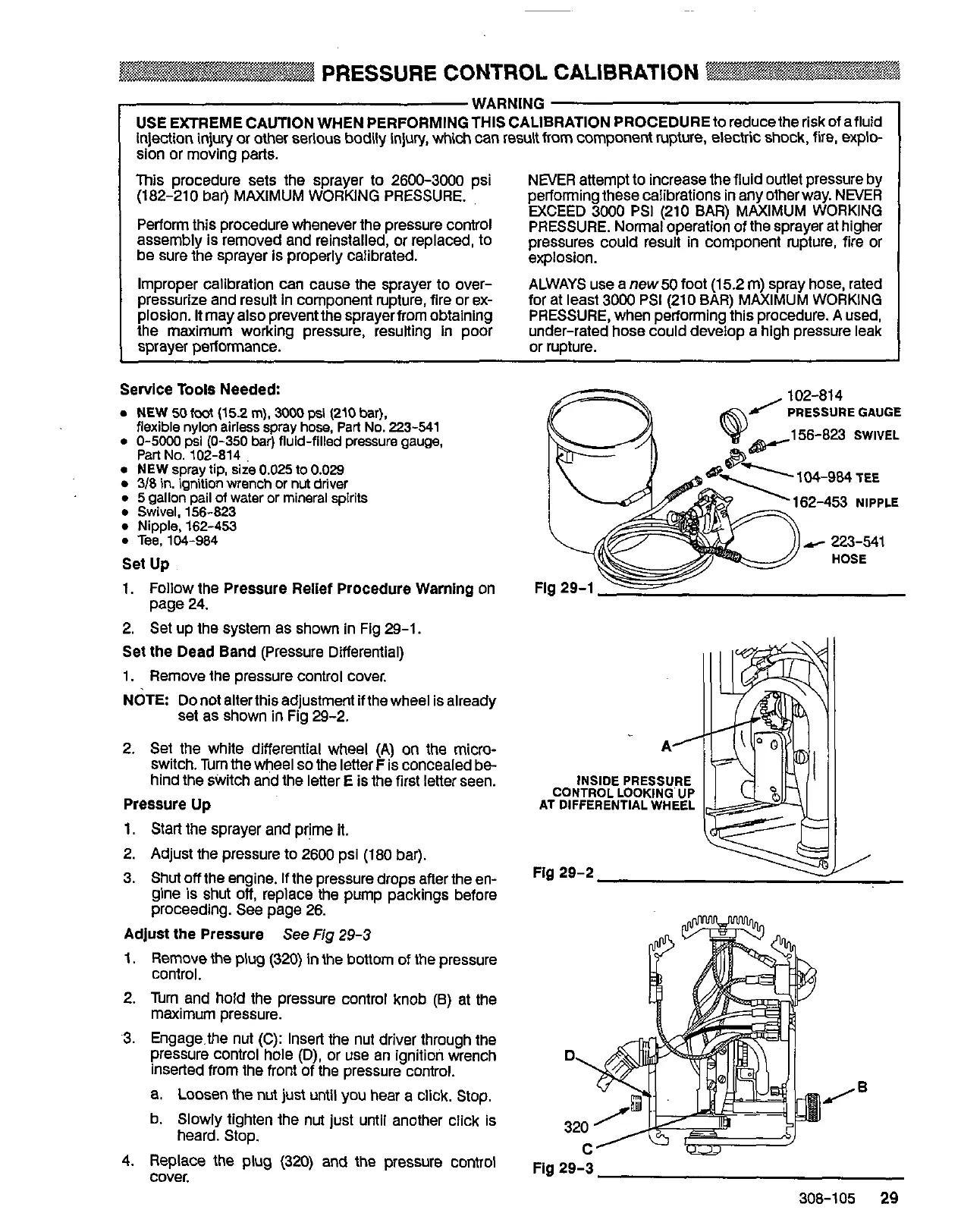

Adjust the Pressure

See

Fig

29-3

1.

Remove the

plug

(320)

in

lhe bottom

of

the pressure

control.

2.

Turn and hold the pressure control knob (6) at the

maximum pressure.

.3. Engage.the nut (C): Insert the nut driver through the

pressure control hole (D), or use an ignition wrench

Inserted from the front of the pressure control.

a.

Loosen

the

nut

just until you hear a click, Stop.

b. Slowly tighten the nut just until another click is

heard. Stop.

4.

Repiace the

plug

(320) and the pressure control

cover.

PRESSUREGAUGE

156-823

SWIVEL

162-453 NIPPLE

Y

223-541

HOSE

Fig

29-3

308-105

29

Loading...

Loading...