~~

~~~~~~~~ PRESSURE CONTROL REPLACEMENT

followthe

Pressure Rellef Procedure Warning

on

page 24 before repairing the sprayer.

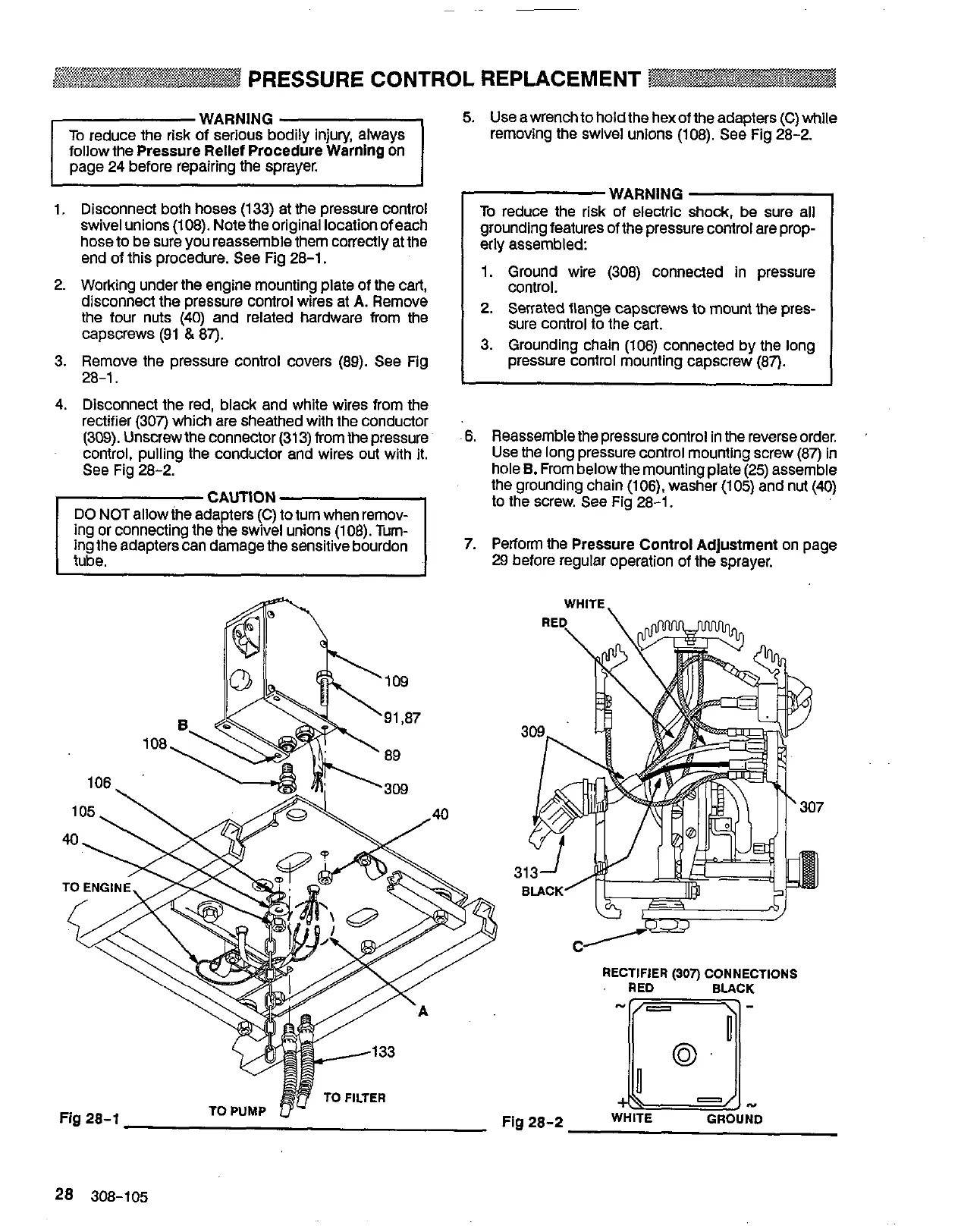

5.

Use

a wrench to hold the hex of the adapters (C) while

removing the swlvel unions (108).

See

Fig 28-2.

1.

2.

3.

4.

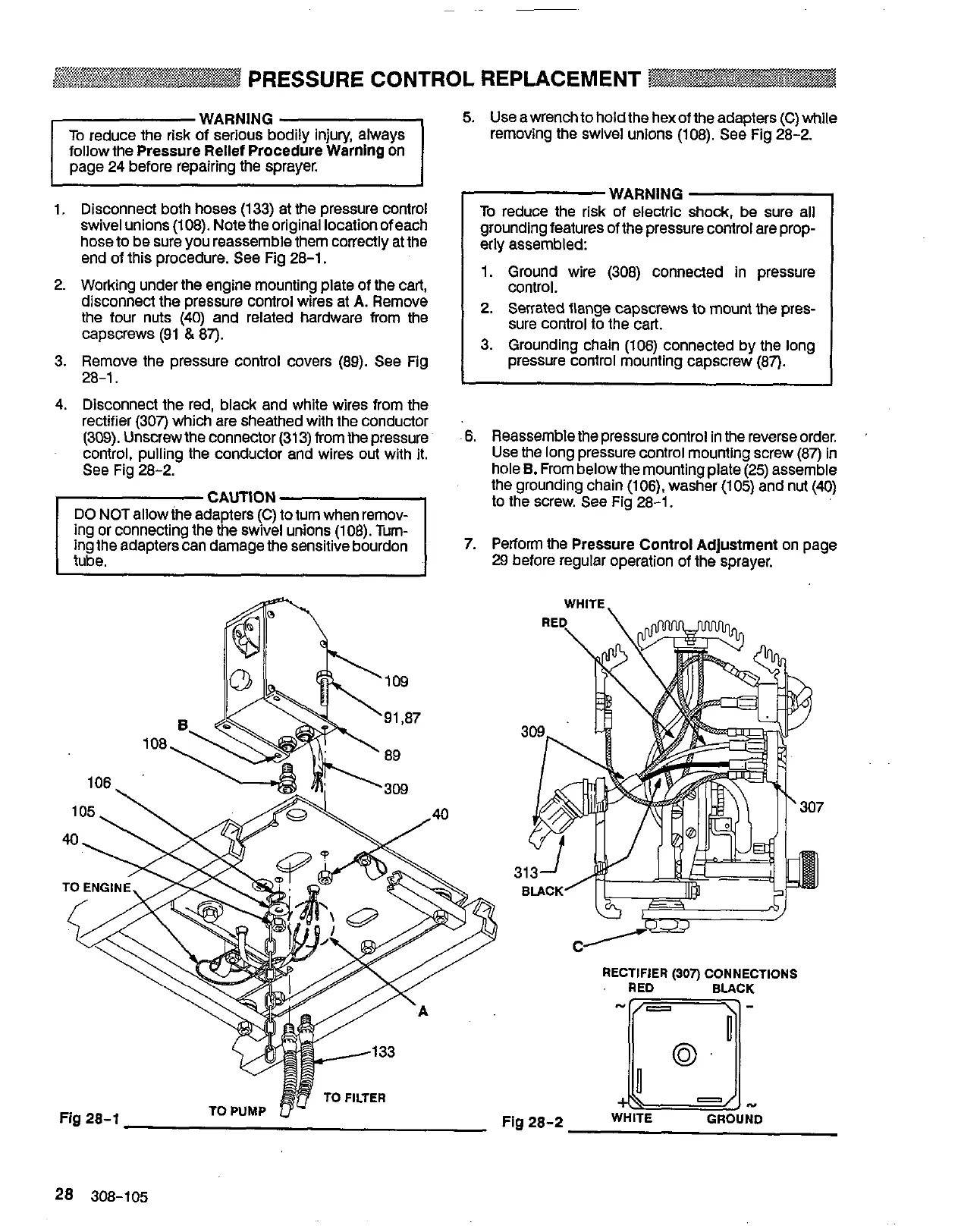

Disconnect both hoses (133) at the pressure control

swivel unions (108). Notethe original locationofeach

hose to be sure you reassemble them correctly at the

end of this procedure.

See

Fig 28-1.

Working under the engine mounting plate of

the

cart,

disconnect the pressure control wires at

A.

Remove

the four nuts

(40)

and related hardware from the

capscrews (91

&

87).

Remove the pressure control covers (89).

See

Fig

28-1.

Disconnect the red, black and white wires from the

rectifier (307) which are sheathed with the conductor

(309).

Unscrew the connector (31

3)

from the pressure

control, pulling the conductor and wires out with it.

See

Fig 28-2.

ing or connecting the the swivel unions (108). Tum-

DO

NOT

allow

the

adapters (C) to tum when remov-

ing the adapters can damagethe sensitive bourdon

WARNING

To

reduce the risk of electric

grounding features of the pressure control are prop-

erly assembled:

1. Ground wire (308) connected In pressure

control.

2.

Serrated flange capscrews

to

mount

the pres-

sure control to the cart.

3. Grounding chain (106) connected by the long

pressure control mounting capscrew (87).

I

I

6.

7.

Reassemble the pressure control

in

the reverse order.

Use

the long pressure control mounting screw

(87)

in

the grounding chain (106). washer (105) and nut

(4)

hole

B.

From belowthe mounting plate

(25)

assemble

to the screw. See Fig 28-1.

Perform

the

Pressure Control Adjustment

on page

29

before regular operation of the sprayer.

WHITE,

RECTIFIER

(307)

CONNECTIONS

RED BLACK

28 308-105

Loading...

Loading...