14 308443

Troubleshooting

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 11.

1. Relieve the pressure before checking or servicing

the equipment.

2. Check all possible problems and causes before

disassembling the pump.

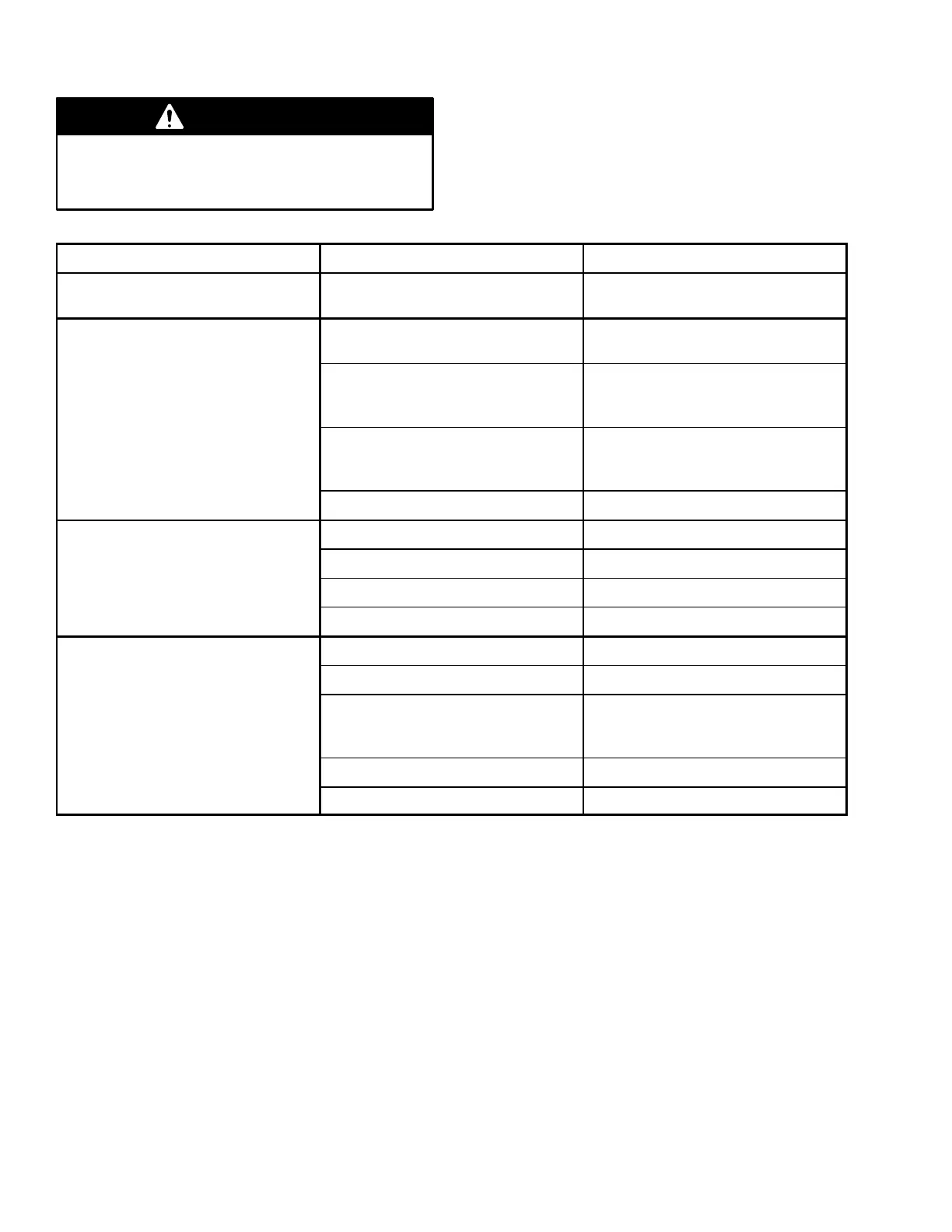

PROBLEM CAUSE SOLUTION

Pump cycles at stall or fails to hold

pressure at stall.

Worn check valve balls (301), seats

(201) or o-rings (202).

Replace. See page 18.

Pump will not cycle, or cycles once

and stops.

Air valve is stuck or dirty. Disassemble and clean air valve.

See pages 16 to 17. Use filtered air.

Check valve ball (301) severely

worn and wedged in seat (201) or

manifold (102 or 103).

Replace ball and seat. See page

18.

Check valve ball (301) is wedged

into seat (201), due to overpressur-

ization.

Install Pressure Relief Valve

(see page 9).

Dispensing valve clogged. Relieve pressure and clear valve.

Pump operates erratically. Clogged suction line. Inspect; clear.

Sticky or leaking balls (301). Clean or replace. See page 18.

Diaphragm ruptured. Replace. See pages 19 to 21.

Restricted exhaust. Remove restriction.

Air bubbles in fluid. Suction line is loose. Tighten.

Diaphragm ruptured. Replace. See pages 19 to 21.

Loose inlet manifold (102), dam-

aged seal between manifold and

seat (201), damaged o-rings (202).

Tighten manifold bolts (106 or 112)

or replace seats (201) or o-rings

(202). See page 18.

Loose fluid side plate (105). Tighten or replace (pages 19 to 21).

Damaged o-ring (108). Replace. See pages 19 to 21.

Loading...

Loading...