14 308155

Service

Reciprocator Repair

NOTES

D The following reciprocator repair instructions are for

Models 239882, 224741, and 224742. For Model

237653 instructions, see accompanying manual

307654.

D Clean and inspect all parts for wear or damage.

Replace parts as needed. For the best results,

always replace all the o-rings and seals when you

disassemble the pump. Repair Kit 223426 is

available. Parts included in the kit are marked with

one asterisk, for example (23*), in the text and

drawings. Always replace the seals (23*, 24*) and

the seals (16*, 44*) together.

D Assembly Tool 189305 is required for

reassembling the reciprocator.

D Loctiter 242 thread sealant and Loctiter Primer T

or Perma-Locr 115 thread sealant and

Perma-Bondr Surface Conditioner I are required.

Be sure their shelf life is within the manufacturer’s

recommendations.

Note: Use Loctiter 609 on yoke (9) and rod (12) on

page 15, step 9 only. Use Loctiter 242 or

Perma-Locr 115 on other threaded surfaces as

required.

Before you begin, drain the oil out of the reciprocator

as follows: Place the reciprocator in a drain pan, push

the piston all the way up/in, then all the way down/out.

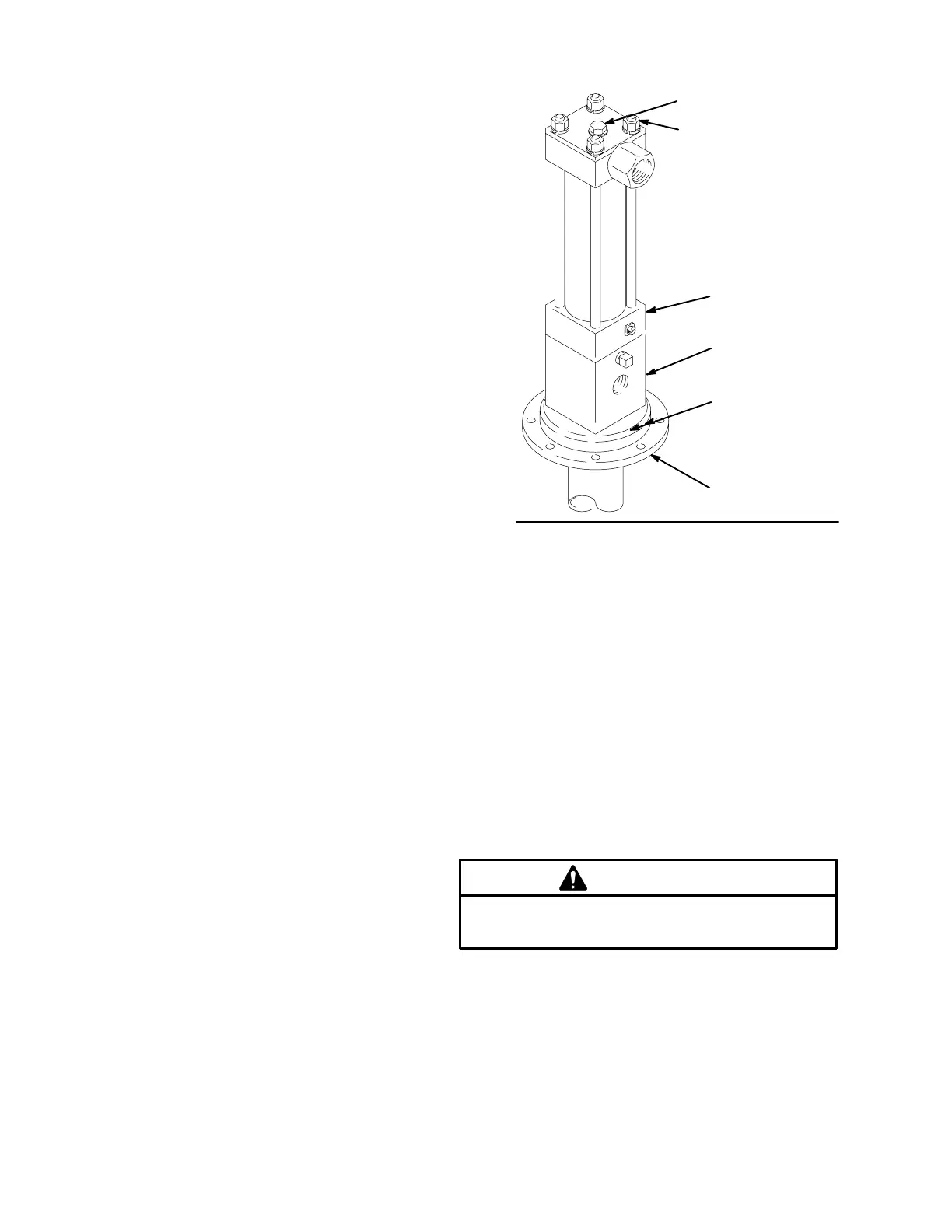

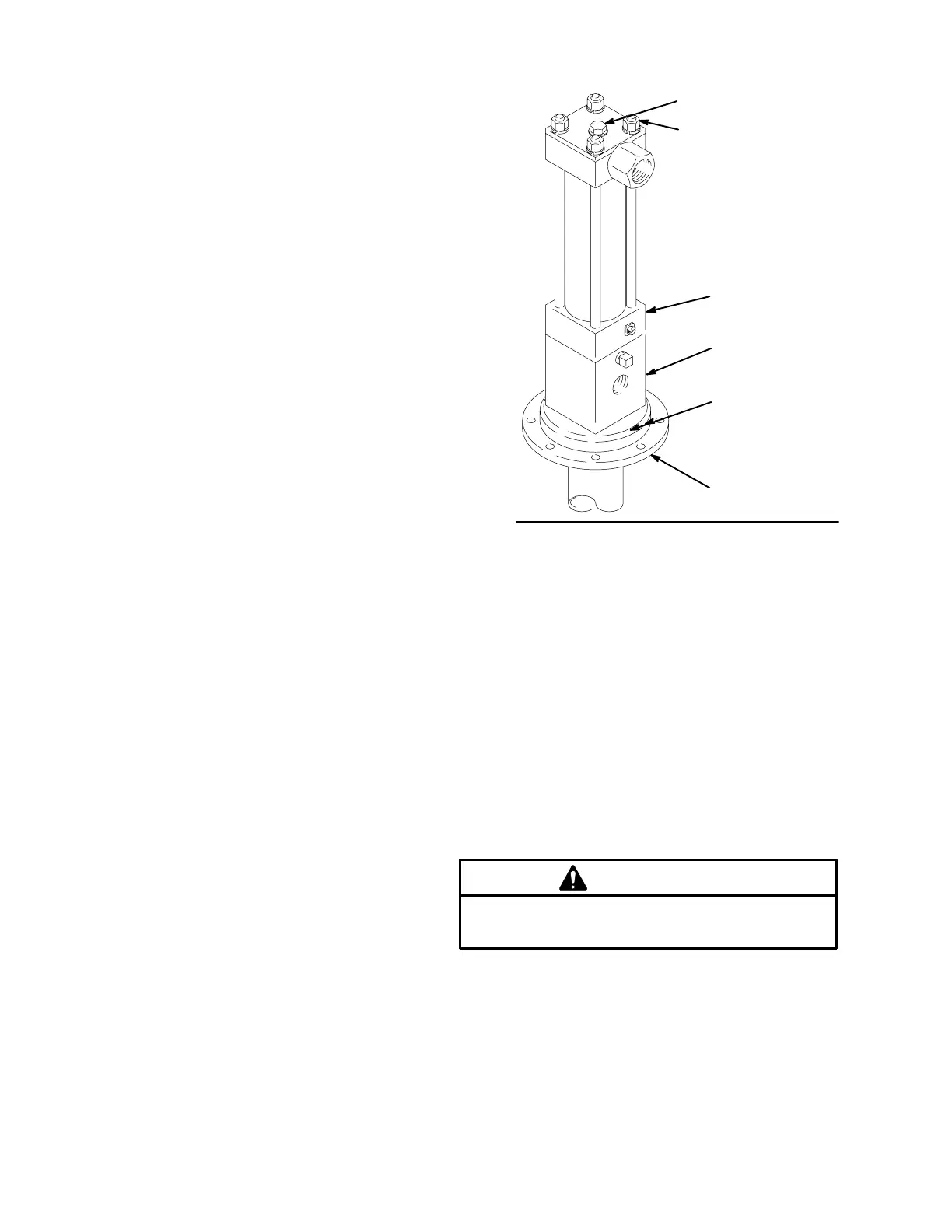

1. Place the adapter (43) in a vise. Remove the four

capscrews (46) and the base (33). Pull the bottom

cap (32) off of the adapter. See Fig. 7. If needed,

replace the seals as described on page 12.

2. Remove the capscrew (3), nuts (36), and

lockwashers (37) on top of the reciprocator. See

Fig. 7.

3. Loosen both nuts on the fluid tube (45). Use a

wrench to rotate the tube fittings (1,58) to the side,

and remove the tube (45). Check the o-rings

(1a,58a) on the fittings, and replace them if they

are worn or damaged. Install plugs in the fittings to

prevent contamination. See Fig. 4 and the Parts

Drawing.

See Fig. 9 for Steps 4 to 13, except where noted.

Fig. 7

43

36,37

33

32

3,39,2

46

(hidden from

view)

06146C

4. Tap on the bottom of the displacement rod (34)

with a plastic mallet to loosen the cylinder (25).

5. Grasp the spool valve assembly (31), and pull it off

the cylinder and tie rods (38). Pull the cylinder and

piston off the bottom cap (32). It is not necessary

to remove the tie rods from the bottom cap.

6. Lay the assembly on its side. Place a clean rag

around the yoke (9) to prevent losing the detent

balls. Slide the yoke sideways off the valve sleeve

(29) while holding the balls (7) and spring (6) in

place.

7. Slide the cylinder (25) off the displacement rod

(34). Hold the hex end of the displacement rod in a

vise, and use a spanner wrench in the pin holes of

the piston (22) to screw it off the rod.

CAUTION

Be careful not to scratch the outside of the dis-

placement rod or the inside of the cylinder.

Loading...

Loading...