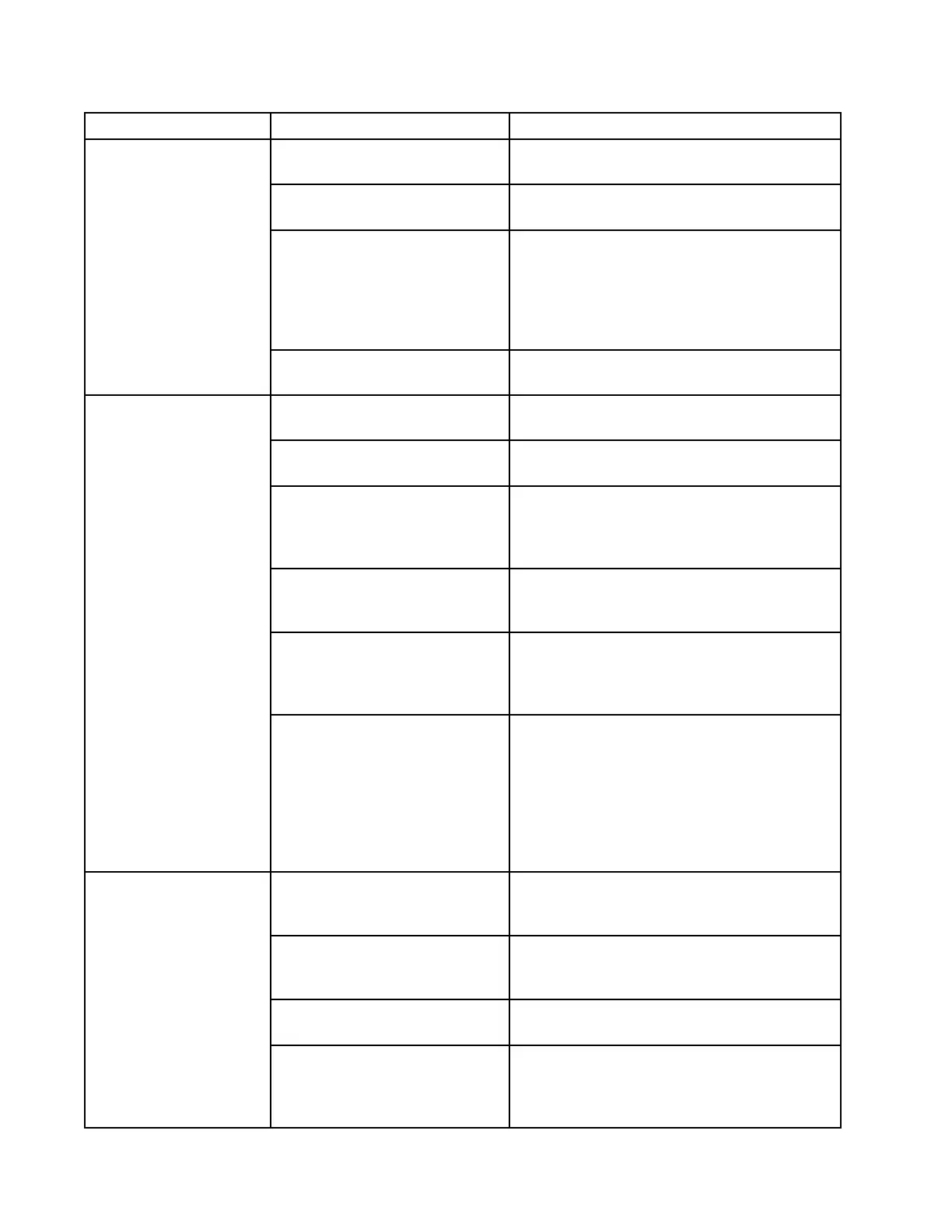

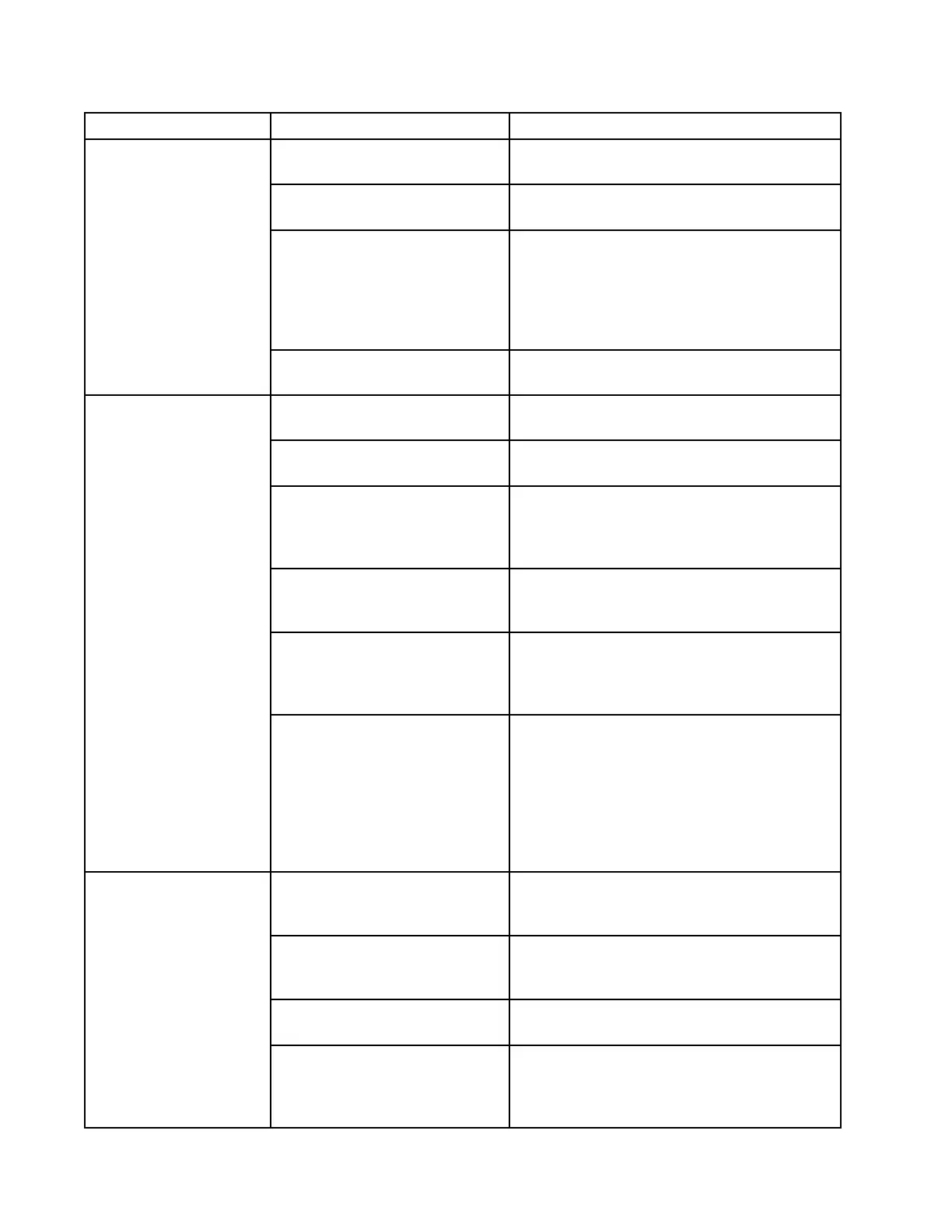

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Themainairregulatorisstuck

open.

SeeRepairingtheMainAirRegulator,page

27.

Theblastcontroltubingisnot

connectedproperly.

Ensureairtubingisroutedandconnected

properly.SeeHoseSchematic,page42.

Electricblastcontrolcircuitis

malfunctioning.

Inspecthosecablefordamagedorshorted

wiring.Checkbatteryandcontrolpanel

connections.EnsureDCpowersourceis

12V.Check3Afuseinsidecontrolpaneland

replaceitifnecessary.Checkcurrentowin

circuit,ifcurrentexists,replacerelay.

Theblastcontrolisnot

engagedbutblastingstill

occurs.

Pneumaticblastcontrolcircuitis

malfunctioning.

SeePneumaticBlastControlCircuit,page26.

Incorrectabrasiveisbeingused.

Usethecorrectabrasive.See

AbrasiveMeteringValveSettings,page16.

Thepotdoesnothavea

sufcientamountofabrasive.

Rellthepotwithabrasive.See

RellingthePotwithAbrasive,page18.

Thepotpressuresettingis

incorrect.

Performthepressurereliefprocedure(see

PressureReliefProcedure,page8)

andresetpotpressure(see

SettingUptheEquipment,page11).

TheAuto-Ventvalvedoesnot

ventairwhenthepotislled.

MakesuretheAuto-Ventvalveisworking.

PerformtheAuto-Ventcleaningprocedure

(seeCleaningtheAuto-VentValve,page30).

Thediaphragmvalveis

malfunctioning.

Performthediaphragmushprocedure(see

FlushingtheDiaphragmValve,page28).

Ifushingdoesnotsolveproblem,see

RepairingtheDiaphragmValve,page29.

Theblastspraypattern

isirregular.

Thereisblockageinsidethe

potorinsidetheabrasivehose

betweenthepotandthepanel.

Makesuretheballvalveisclosed,then

disconnectthecam-lockcoupler.Openthe

abrasiveballvalveslightlyandmakesure

abrasiveisowingfromtheabrasivehose.

Ifnot,followtheshutdownprocedure(see

ShuttingDown,page19).Thoroughlyush

thepotandthemediahoseafterdraining

mediaandwater.

Theunitisnotonalevelsurface.Placetheunitonalevelsurface.Ifthisis

impossible,theAuto-Ventmustbeonthe

highersideoftheunit.

Theinitialpotpressureisnotset

correctly.

Conrmthattheauto-ventvalveisworking

andsetinitialpotpressure30psi(2.0bar,

0.20MPa)abovetheblastpressure.

TheAuto-Ventismalfunctioning.Performauto-ventcleaningprocedure(see

CleaningtheAuto-VentValve,page30).

Astronghoserecoil

occursfrequentlywhen

theblastcontrolswitch

isengaged.

Thediaphragmneedstobe

ushed.

Performthediaphragmushprocedure(see

FlushingtheDiaphragmValve,page28).

Ifushingdoesnotsolvetheproblem,see

RepairingtheDiaphragmValve,page29.

24

334666C

Loading...

Loading...