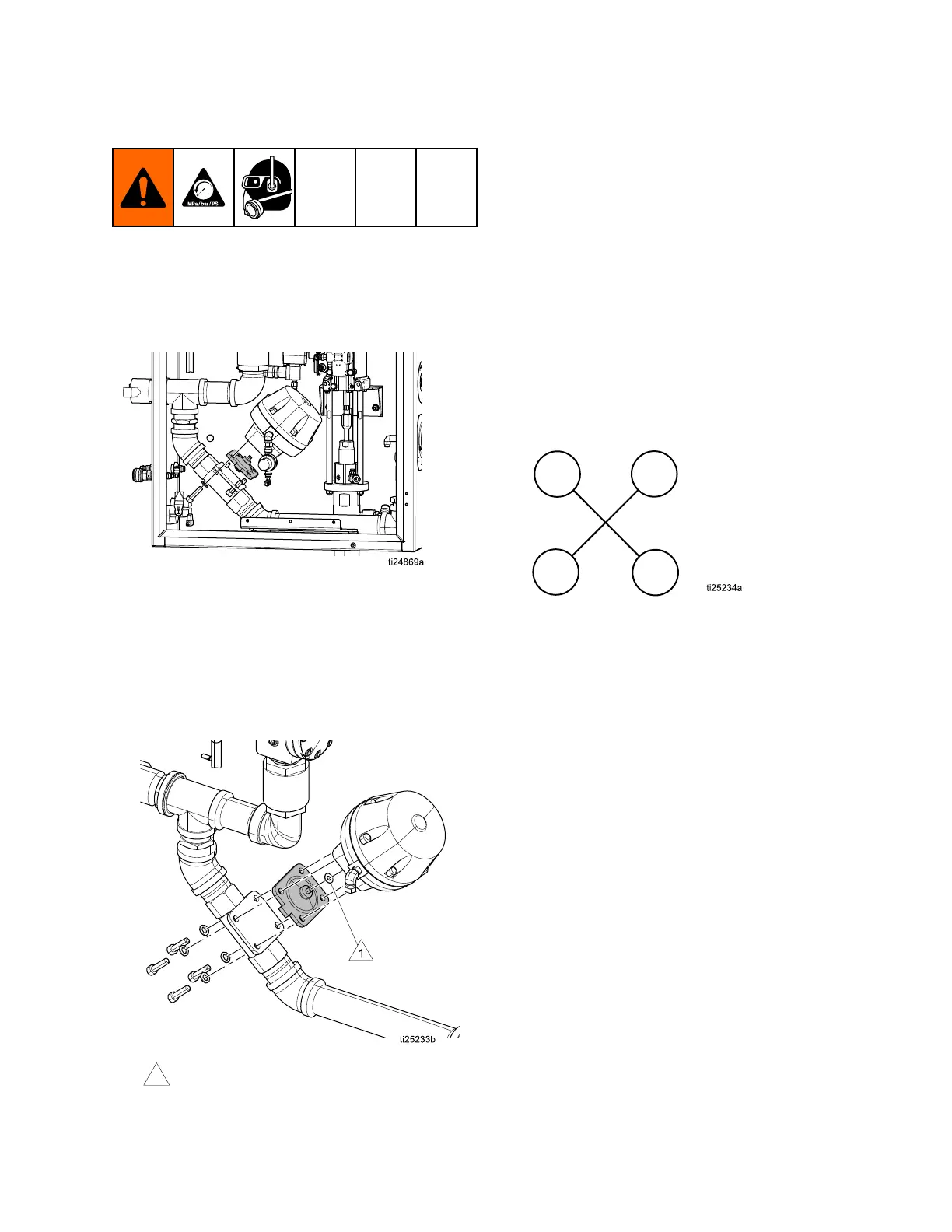

Repair

Repairing Repairing

Repairing

the the

the

Diaphragm Diaphragm

Diaphragm

Valve Valve

Valve

SeeCommonSpareParts,page47forrepairkits.

NOTE: NOTE:

NOTE:

Thediaphragmcanbereplacedwithout

removingtheassemblyfromthepanel.Youwillneed

an8mmAllenwrenchfortheEQ400anda6mm

fortheEQ200.

1.PerformthePressureReliefProcedure,page8.

2.Applymorethan80psi(5.5Bar,MPa)air

pressuretotheregulatorinlettocausethepiston

toretract.

3.Loosenall4Allen-headcap-boltsevenlyand

thenremovethemcompletelywhilesupporting

thecanisterofthediaphragmvalve.

EQ200shown,EQ400usestwoshims.

NOTE: NOTE:

NOTE:

Donotdisassemblethecanister.

4.Replacethediaphragm(naturalrubber

compound)andhand-tightenit(onlyasfaras

necessary)toestablishthealignmentwiththe

canister.

NOTE: NOTE:

NOTE:

Thereareoneortwoshimsbetween

thediaphragmandtheactuator.Keepthe

shimsandreusethem(theydonotcomewith

thereplacementdiaphragm).Donotcause

anypre-loadortorqueonthediaphragmby

over-tighteningitinamisalignedposition.

5.Insertall4Allen-headcapboltsandhand-tighten.

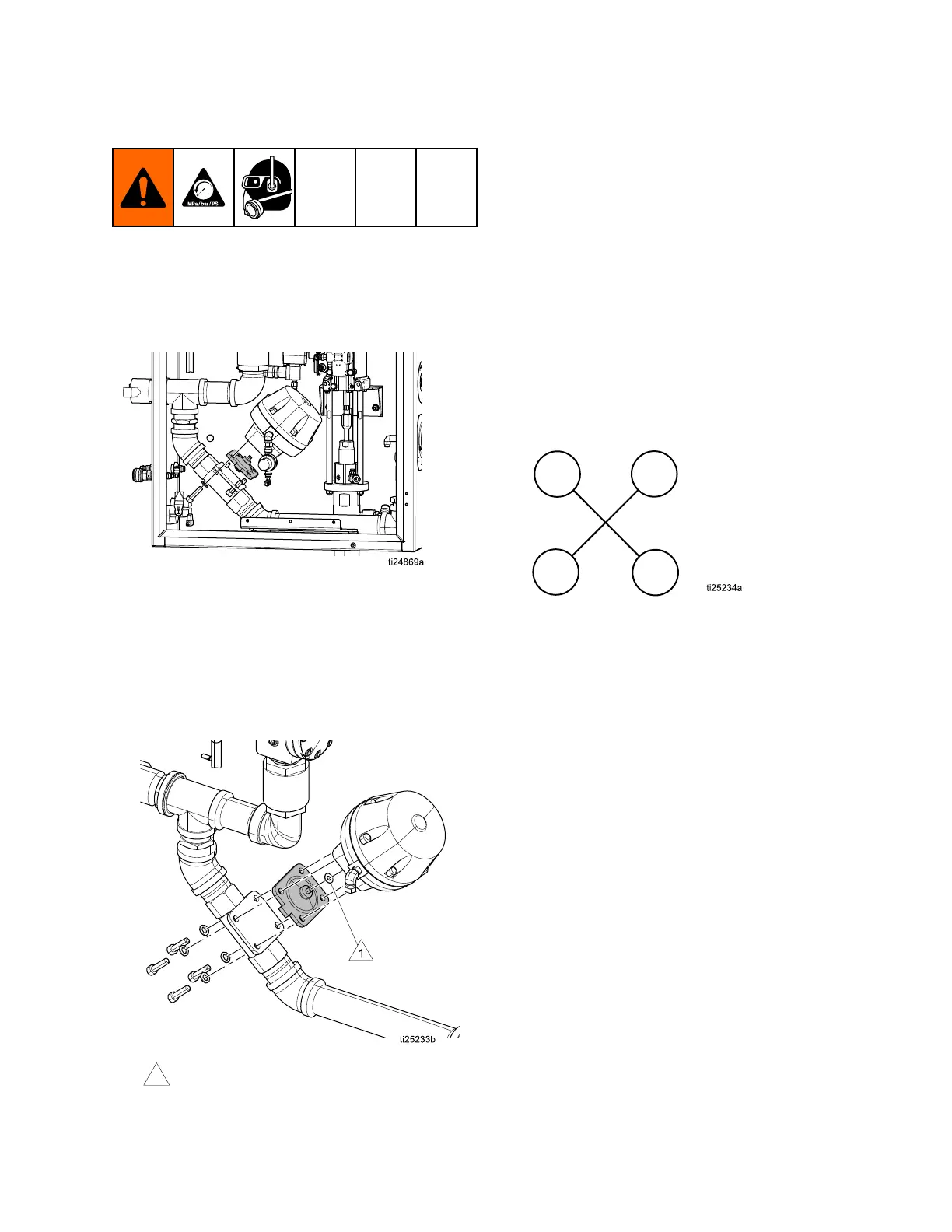

6.Tightenthecap-boltsinanalternatingpattern

(seeimagebelow)to80+/-8in-lb(9+/-0.9N•m).

Thiswillcauseaslightbulgeinthediaphragm

betweenthecanisterandthestainlesssteel

casting.

7.Relievethepressureappliedinstep2.

8.Testandconrmthattheunitisworkingproperly.

NOTE: NOTE:

NOTE:

Thiscanbedoneusingonlywaterto

chargetheequipment–thereisnoneedtouse

abrasiveforthistest.

334666C 29

Loading...

Loading...