~~ ~

~

REMOVING

and

REPLACING PRESSURE CONTROL

I

,

..

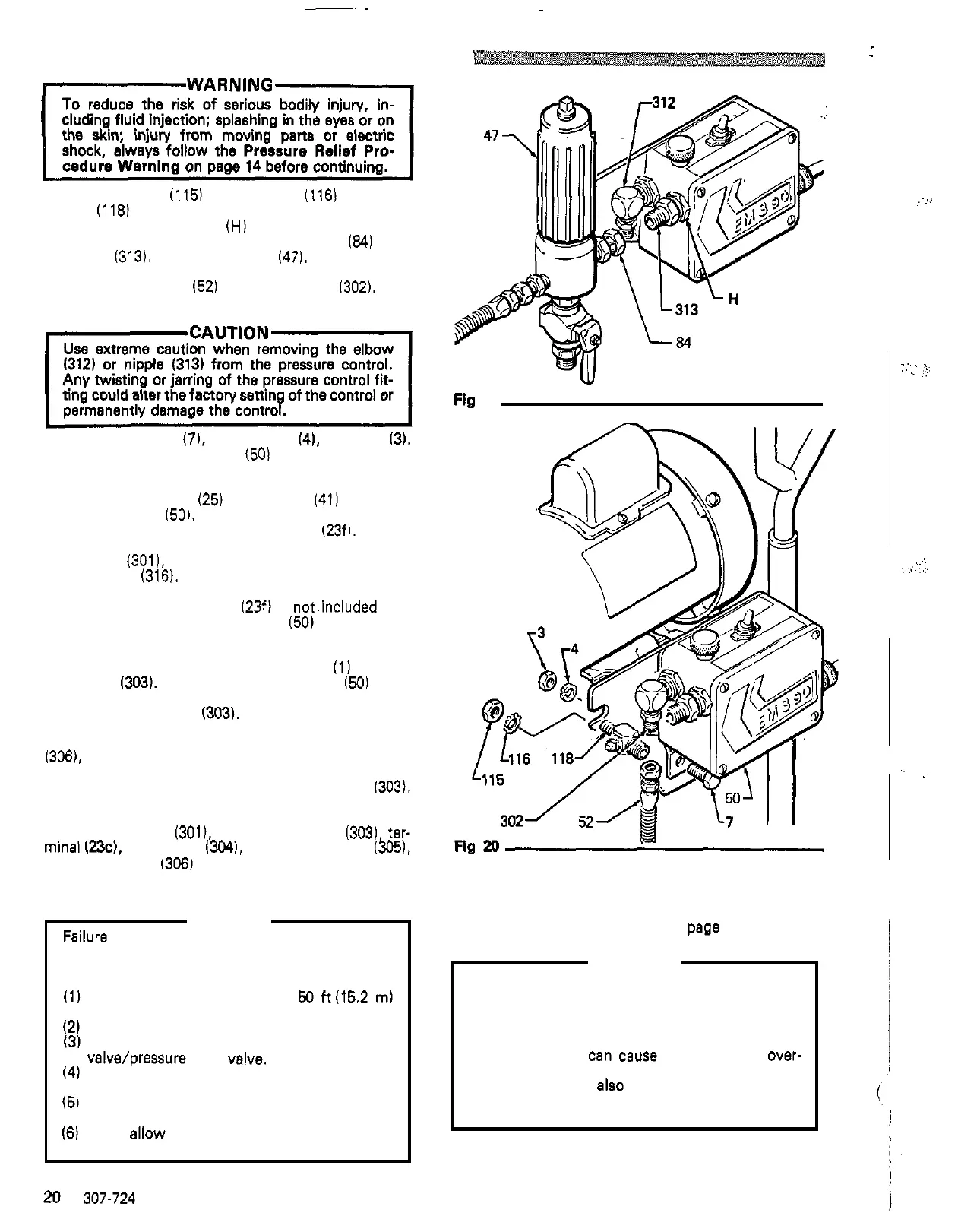

adapter (118) holding the filter to the mounting bracket.

Remove the nut

(115) and washer (116) from the

with

a

wrench and unscrew the swivel union

(84)

from

See

Fig

20.

Hold the nut

(H)

at

the pressure control

the nipple

(313). Remove the filter (47).

See

Fig 19.

Disconnect the hose

(52) from the nipple 1302).

See

Fig

20.

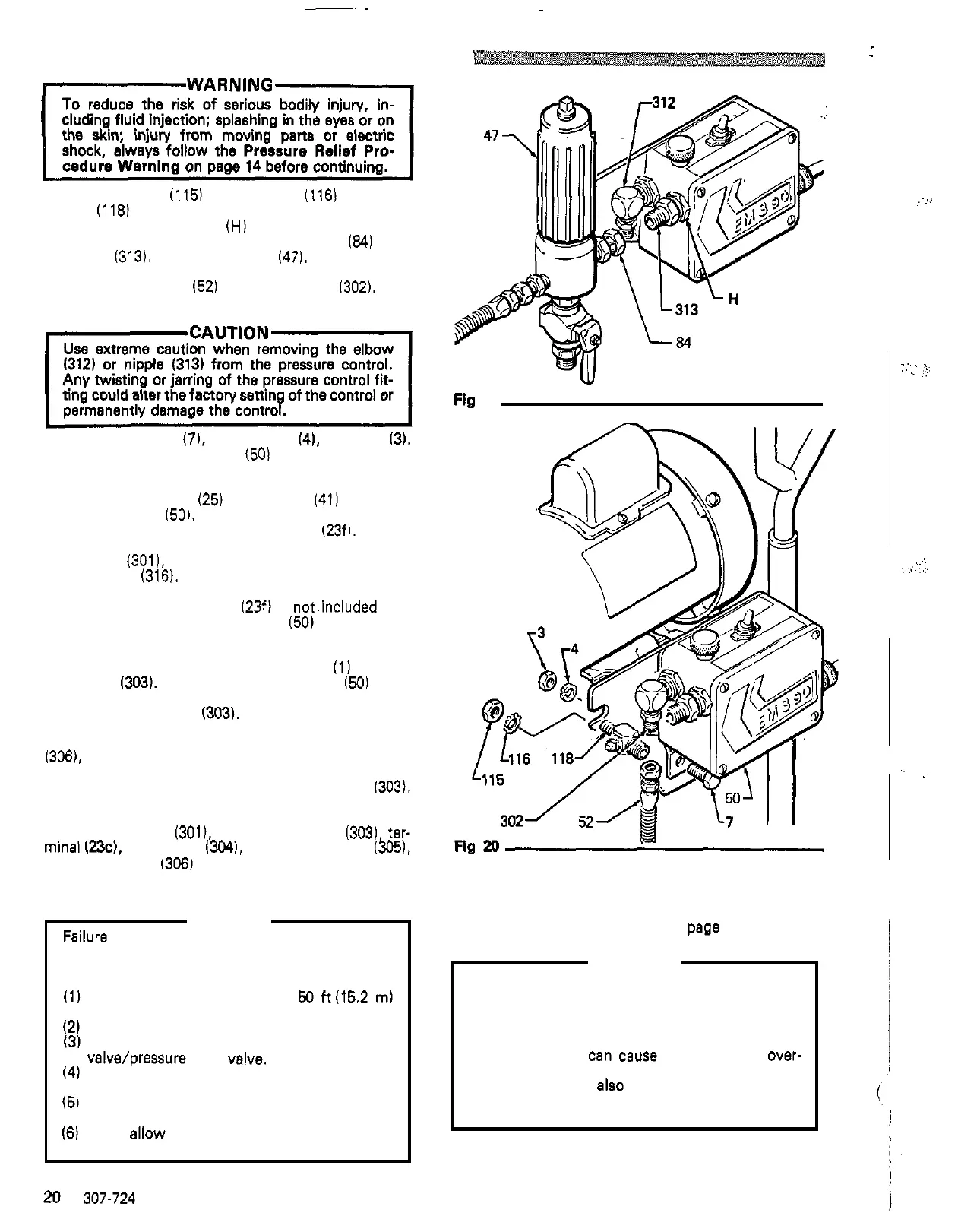

Remove the screws (7), lockwashers

(4),

and nuts

(3).

Remove the pressure control

(50)

from the frame.

See

Fig

20.

Remove the screws

(25)

and cover (41) from the

pressure control

(50).

Disconnect the red, pink and

brown motor leads from the circuit board

(23f). Discon-

nect the green and yellow motor lead from the groun

-

ding screw (3011, and the black motor lead from the

toggle switch

(316). See Fig 21.

NOTE:

The circuit board

(23f)

is

not.included with

the pressure control

(50)

replacement

assembly. Order separately if needed.

connector

(303).

Pull

the pressure control

150)

away

Unscrew the nut on the end of the conduit

(1) from the

from the conduit while carefully guiding the wires

through

the

connector

(303).

See

Fig 21.

Loosen the knurled pert of the power cord strain relief

the strain relief up on the power cord to provide

(306).

and unscrew

it

from the pressure control. Slide

clearance, and unscrew the conduit connector

(303).

See

Fig

21.

Remove

the

screw

(301).

conduit connector (303). ter-

and strain relief (306) from the old pressure control.

mind 123c), lockwasher

1304).

power supply cord

(305).

Replace any damaged parts. Assemble these parts to

the new pressure control.

CAUTION

Failure to observe the following may cause poor

performance or excessive pressure end permanent

damage to the pressure control:

(1)

Always use nylon spray hose

et

50

ft

(15.2 m)

(2)

Never

use

a wire braid spray hose.

13) Never attach

a

spray hose to the filter drain

(4) Never add any type of shut

off

device between

valve/pressure relief velve.

(5)

Be

sure to check filter for clogging or incorrect

the pump outlet and the spray gun.

(6)

Never ellow flushing water or water base paint

assembly if tip clogging frequency increases.

to freeze in the system.

minimum length.

20

307-724

Fig

19

Replace in the reverse order of disassembly and then

calibrate the pressure control.

See

pege

22.

WARNING

whenever

a

new or used microswitch or pressure

The pressure control

MUST

be calibrated

control assembly

is

removed and reinstalled or

replaced to be sure the control is properly

calibrated. Failure to properly calibrate the

pressure control

can cause the sprayer to over-

explosion.

It

may

also

prevent the sprayer from

pressurize end result in component rupture, fire or

obtaining

the

maximum working pressure which

would result in poor sprayer performance.

.

,

,::1

..

..

.....

..'.,

,:)'

..

......

4

..

.

,.

..<.,.>

.. .

. .

..

Loading...

Loading...