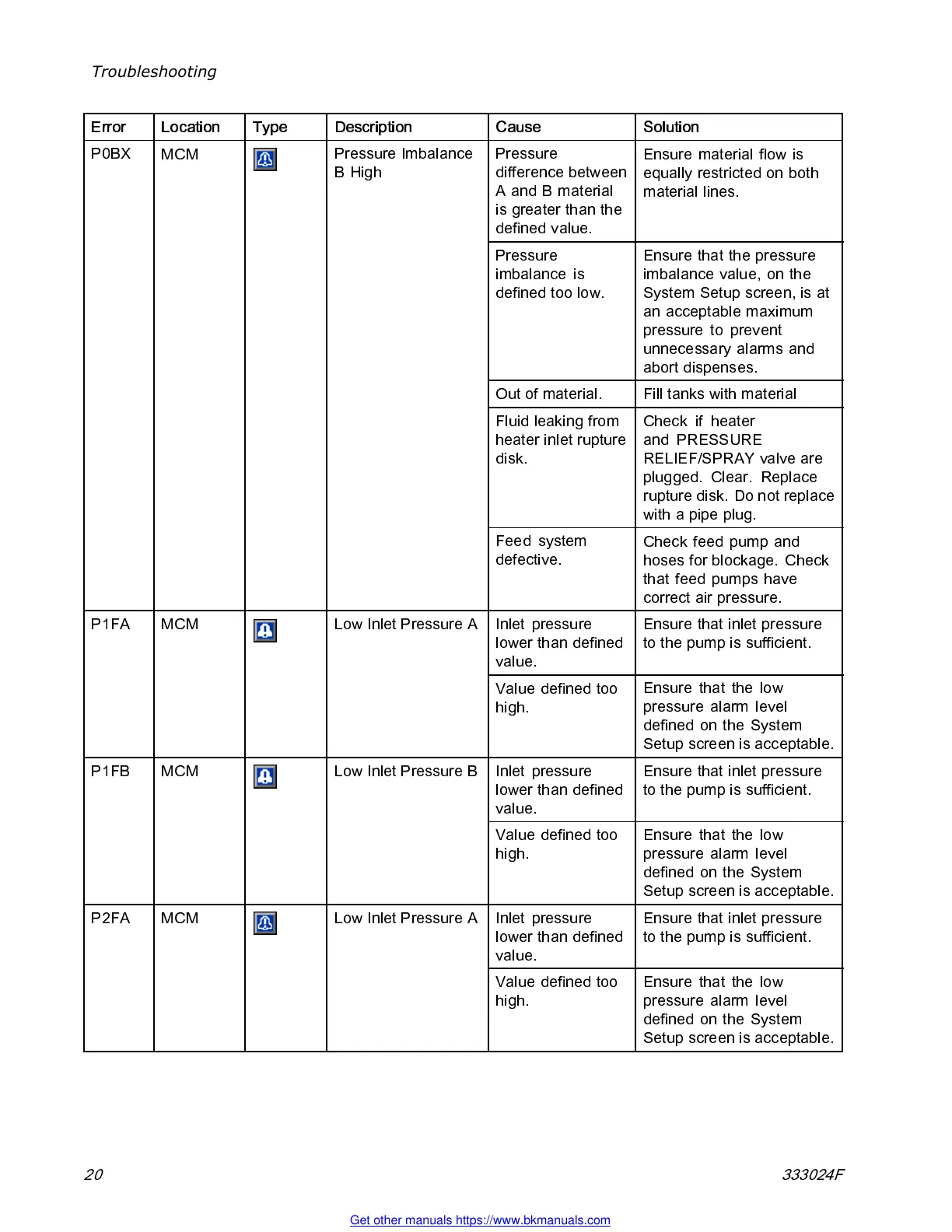

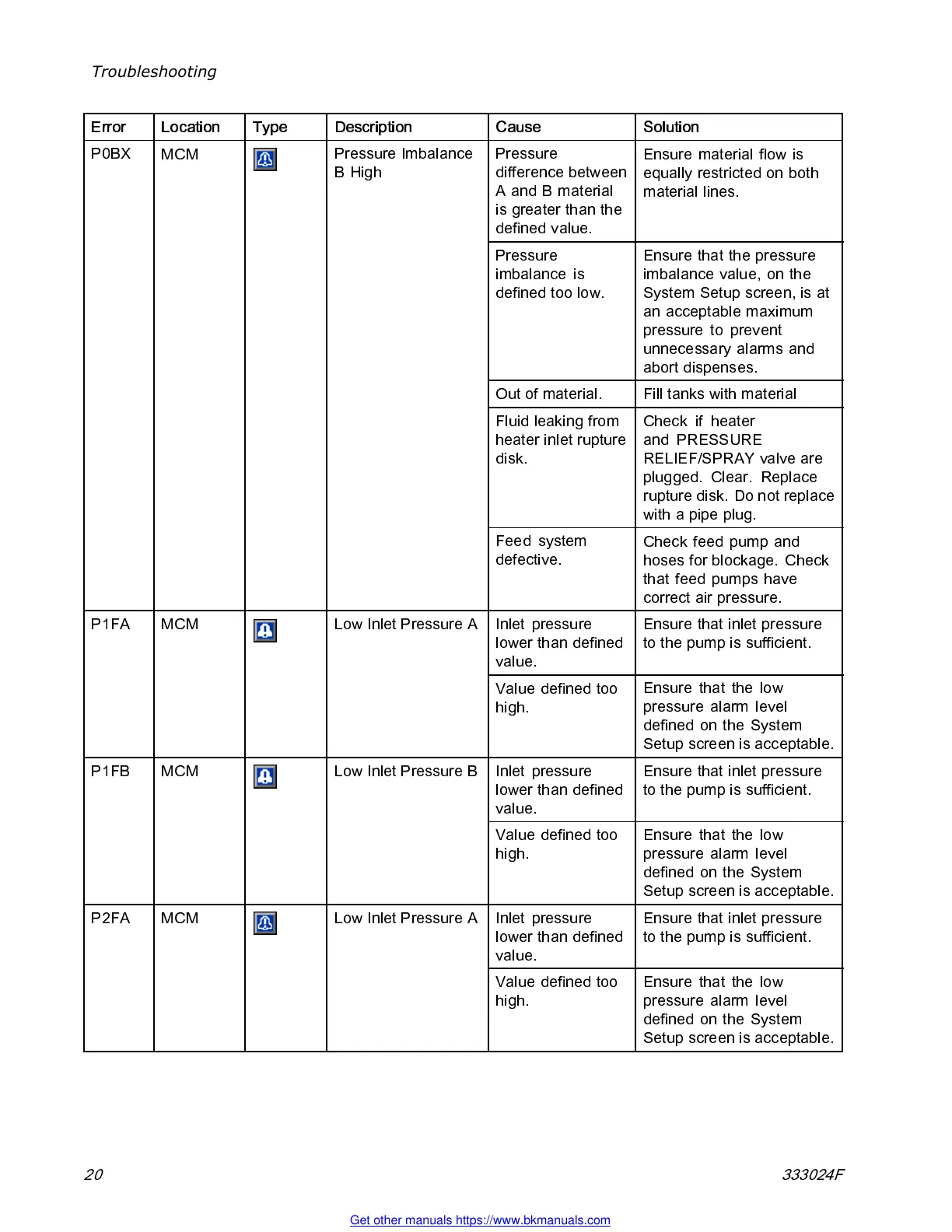

Troubleshooting

Error Location Type Description

Cause Solution

Pressure

difference between

AandBmaterial

is greater than the

defined value.

Ensure material flow is

equa lly restric ted on both

material lines.

Pressure

imbalance is

defined too low.

Ens ure tha t the pressure

imbalance value, on the

System Se tup screen, is at

an acceptable maximum

pressure to prevent

unnecessary alarms and

abort dispenses.

Out of material. Fill tanks with material

Fluid leaking from

heater inlet rupture

disk.

Check if heater

and PRESSURE

RELIEF/SPRAY valve are

plugged. Clear. Replace

rupture disk. Do not replace

withapipeplug.

P0BX

MCM

Pressure Imbalance

BHigh

Feed system

defective.

Check feed pump and

hoses for blockage. Check

that feed pumps have

correct air pressure.

Inlet pressure

lower than defined

value.

Ens ure that inlet pressure

to the pump is sufficient.

P1FA

MCM

Low Inlet Pressure A

Value defined too

high.

Ens ure that the low

pressure alarm level

defined on the System

Setup screen is acceptable.

Inlet pressure

lower than defined

value.

Ens ure that inlet pressure

to the pump is sufficient.

P1FB

MCM

Low Inlet Pressure B

Value defined too

high.

Ens ure that the low

pressure alarm level

defined on the System

Setup screen is acceptable.

Inlet pressure

lower than defined

value.

Ens ure that inlet pressure

to the pump is sufficient.

P2FA

MCM

Low Inlet Pressure A

Value defined too

high.

Ens ure that the low

pressure alarm level

defined on the System

Setup screen is acceptable.

20 333024F

Get other manuals https://www.bkmanuals.com

Loading...

Loading...